Abstract

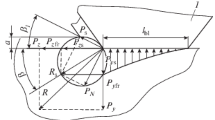

A model of the wheel–workpiece interaction in peripheral surface grinding is developed. The goal is to predict the microrelief of the blank after repeated microcutting. Models of the abrasive grain, the grinding wheel, individual scratches, and the three-dimensional microrelief of the blank are presented. Experimental results confirm the validity of the model.

Similar content being viewed by others

References

Kozlov, A.M. and Kozlov, A.A., Shaping the surface topology of cylindrical components by means of an abrasive tool, Russ. Eng. Res., 2009, vol. 29, no. 7, pp. 743–746.

Shirokov, A.V. and Osipov, A.P., Modeling of the polished surface forming, Izv. Samar. Nauch. Tsentra, Ross. Akad. Nauk, 2011, vol. 13, nos. 4–3, pp. 905–909.

Zhou, X. and Xi, F., Modeling and predicting surface roughness of the grinding process, Int. J. Mach. Tools Manuf., 2002, no. 42, pp. 969–977.

Hecker, R.L. and Liang, S.Y., Predictive modeling of surface roughness in grinding, Int. J. Mach. Tools Manuf., 2003, no. 43, pp. 755–761.

Salisbury, E.J., Domala, K.V., Moon, K.S., et al., A three-dimensional model for the surface texture in surface grinding, Part 2: Grinding wheel surface texture model, ASME Int. Manuf. Sci. Eng. Trans., 2001, vol. 123, no. 4, pp. 582–590.

Nguyen, T.A. and Butler, D.L., Simulation of surface grinding process, part 2: Interaction of the abrasive grain with the work piece, Int. J. Mach. Tools Manuf., 2005, vol. 45, no. 11, pp. 1329–1336.

Ardashev, D.V., Contact phenomena of wear in the pair “abrasive–steel,” Tekhnol. Mashinostr., 2014, no. 9, pp. 19–21.

Ardashev, D.V., Physicochemical wear of abrasive grains during grinding processes, J. Frict. Wear, 2014, vol. 35, no. 4, pp. 284–289.

D’yakonov, A.A., Blank-cutter interaction in highspeed cutting, Russ. Eng. Res., 2014, vol. 34, no. 12, pp. 775–777.

D’yakonov, A.A., Effective cutting conditions in abrasive machining, Russ. Eng. Res., 2014, vol. 34, no. 12, pp. 778–780.

D’yakonov, A.A. and Shipulin, L.V., Selecting the cutting conditions for plane grinding by the wheel periphery, Russ. Eng. Res., 2014, vol. 34, no. 12, pp. 814–816.

Author information

Authors and Affiliations

Corresponding author

Additional information

Original Russian Text © A.A. D’yakonov, L.V. Shipulin, 2015, published in STIN, 2015, No. 6, pp. 23–26.

About this article

Cite this article

D’yakonov, A.A., Shipulin, L.V. Wheel–workpiece interaction in peripheral surface grinding. Russ. Engin. Res. 36, 63–66 (2016). https://doi.org/10.3103/S1068798X16010093

Published:

Issue Date:

DOI: https://doi.org/10.3103/S1068798X16010093