Abstract

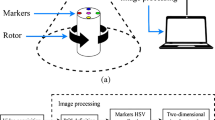

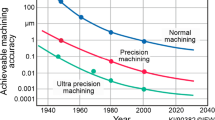

More reliable preliminary monitoring of a machine-tool spindle is permitted by the use of an information and measuring system based on vibroacoustic and thermal analysis of the bearings

Similar content being viewed by others

References

Grigoriev, S.N., Kozochkin, M.P., Sabirov, F.S., and Kutin, A.A., Diagnostic systems as basis for technological improvement, Procedia CIRP, 2012, vol. 1, no. 1, pp. 599–604.

Sabirov, F.S. and Sabirov, S.Y., Diagnostics and control of the accuracy of axis drives for automatically controlled multicoordinate metal cutting machines, Meas. Techn., 2011, vol. 54, no. 8, pp. 879–882.

Kochinev, N.A. and Sabirov, F.S., Measurement of the dynamic characteristics of machine tools by a pulse loading method, Meas. Techn., 2009, vol. 52, no. 6, pp. 621–625.

Kozochkin, M.P. and Sabirov, F.S., Attractors in cutting and their future use in diagnostics, Meas. Techn., 2009, vol. 52, no. 2, pp. 166–171.

Kozochkin, M.P., Kochinev, N.A., and Sabirov, F.S., Diagnostics and monitoring of complex production processes using measurement of vibration-acoustic signals, Meas. Techn., 2006, vol. 49, no. 7, pp. 672–678.

Kozochkin, M.P., Porvatov, A.N., and Sabirov, F.S., The fitting of technological equipment with data-measuring systems, Izmerit. Tekhn., 2012, no. 5, pp. 29–32.

Kozochkin, M.P., Porvatov, A.N., and Sabirov, F.S., The fitting of technological equipment with data-measuring systems, Meas. Techn., 2012, vol. 55, no. 5, pp. 530–534.

Porvatov, A.N., An approach to the development of an information system for the diagnostics of lathe equipment with the use of simulation modeling, Meas. Techn., 2011, vol. 54, no. 6, pp. 650–654.

Grigor’ev, S.N., Kozochkin, M.P., Sabirov, F.S., and Sinopal’nikov, V.A., Current problems in machinetool diagnostics, Vestn. MGTU Stankin, 2010, no. 4, pp. 27–36.

Sinopal’nikov, V.A. and Grigor’ev, S.N., Nadezhnost’ i diagnostika tekhnologicheskikh sistem (Reliability and Diagnostics of Technological Systems), Moscow: Yanus-K, 2003.

Grigor’ev, S.N., Designing numerically controlled technological systems, Mekhatron., Avtomat., Upravl., 2011, no. 4, pp. 19–26.

Grigor’ev, S.N., Creating a multifunctional numerical control system for technological equipment, on the basis of a common core with open modular architecture, Prib. Sist., Upravl., Kontr., Diagn., 2011, no. 5, pp. 1–11.

Porvatov, A.N., An approach to the development of an information system for the diagnostics of lathe equipment with the use of simulation modeling, Meas. Techn., 2011, vol. 54, no. 6, pp. 650–654.

Kamnev, V.A., Kuzovkin, V.A., and Porvatov, A.N., Automatic diagnostic test bench for the dressing spindle of a grinding machine, Vestn. MGTU Stankin, 2013, no. 3(26), pp. 37–40.

Kozochkin, M.P., Maslov, A.R., and Porvatov, A.N., Assessing the dynamic rigidity of a micromilling machine, Vestn. MGTU Stankin, 2013, no. 2(25), pp. 12–26.

Author information

Authors and Affiliations

Corresponding author

Additional information

Original Russian Text © V.A. Kamnev, A.N. Porvatov, 2014, published in STIN, 2014, No. 12, pp. 29–31.

About this article

Cite this article

Kamnev, V.A., Porvatov, A.N. Efficient preliminary monitoring of a machine-tool spindle by means of information and measuring systems. Russ. Engin. Res. 35, 470–472 (2015). https://doi.org/10.3103/S1068798X15060052

Published:

Issue Date:

DOI: https://doi.org/10.3103/S1068798X15060052