Abstract

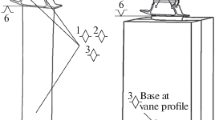

A highly effective method used for machining geometrically complex surfaces in gas-turbine blades is considered. This method is widely adopted for the machining of materials that are difficult to cut, such as high-temperature nickel alloys and cobalt alloys used for the manufacture of gas-turbine components. It provides the basis for the machining of complex surfaces in the clamped sections of the turbine blade.

Similar content being viewed by others

References

Poletaev, V.A., Technologiya avtomatizirovannogo proizvodstva lopatok gazoturbinnykh dvigatelei (Automated Production of Gas-Turbine Blades), Moscow: Mashinostroenie, 2006.

Poletaev, V.A. and Volkov, D.I., Glubinnoe shlifovanie lopatok turbin (Deep Grinding of Turbine Blades), Moscow: Mashinostroenie, 2009.

Poletaev, V.A. and Tsvetkov, E.V., Improving the automated grinding of gasturbine blades, Naukoemk. Tekhnol. Mashinostr., 2013, no. 4, pp. 34–37.

Author information

Authors and Affiliations

Corresponding author

About this article

Cite this article

Poletaev, V.A., Tsvetkov, E.V. Automated machining of turbine blades. Russ. Engin. Res. 35, 212–214 (2015). https://doi.org/10.3103/S1068798X15030168

Published:

Issue Date:

DOI: https://doi.org/10.3103/S1068798X15030168