Abstract

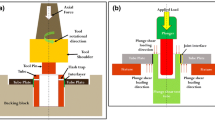

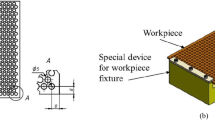

Surface treatment of titanium joint components so as to prevent jamming and increase their wear resistance is considered. Threaded joints in titanium pipes with a modified surface undergo bench tests.

Similar content being viewed by others

References

Vul’f, B.K., Termicheskaya obrabotka titanovykh splavov (Heat Treatment of Titanium Alloys), Moscow: Metallurgiya, 1969.

Vinogradov, Yu.M., Dovzhenko, V.D., and Polikarpova, E.M., Chemicothermal treatment of titanium alloys, Titan dlya narodnogo khozyaistva (Industrial Applications of Titanium), Moscow: Nauka, 1976, pp. 262–267.

Yanko, V.M., Veretennikov, Yu.N., and Lifshits, O.Z., Chemicothermal treatment of VT6 alloy to improve its antifrictional properties, Metalloved. Term. Obrab. Met., 1982, no. 5, pp. 52–54.

Yanko, V.M., Determining the contact stress in loaded threaded joints of titanium pumping pipe, Khim. Neftegaz. Mash., 2008, no. 7, pp. 12–13.

Yanko, V.M., Manufacture of conical thread on pipeline components and methods of improving joint sealing, Vestn. Mashinostr., 2013, no. 3, pp. 41–42.

USSR Inventor’s Certificate 1068539.

Author information

Authors and Affiliations

Corresponding author

Additional information

Original Russian Text © V.M. Yanko, 2013, published in Vestnik Mashinostroeniya, 2013, No. 11, pp. 23–24.

About this article

Cite this article

Yanko, V.M. Increasing joint life and reliability by surface treatment of thread on titanium pipe. Russ. Engin. Res. 34, 69–70 (2014). https://doi.org/10.3103/S1068798X14020166

Published:

Issue Date:

DOI: https://doi.org/10.3103/S1068798X14020166