Abstract

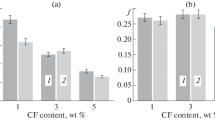

It is shown analytically that the empirical wear law takes account of two fundamentally different wear mechanisms. Whether adhesive or fatigue wear predominates will depend on the selection of the frictional power. Comparison of the coefficients in the empirical law demonstrates the role of the filler in reducing the wear rate of composites.

Similar content being viewed by others

References

Belyi, V.A., Sviridenok, A.I., Petrokovets, M.I., and Savkin, V.G., Trenie i iznos materialov na osnove polimerov (Friction and Wear of Polymer-Based Materials), Minsk: Nauka i Tekhnika, 1976.

Bowden, F.P. and Tabor, D., Friction and Lubrication of Solids, London: OUP, 1954.

Kragel’skii, I.V., Dobychin, M.N., and Kombalov, V.S., Osnovy raschetov na trenie i iznos (Principles of Frictional and Wear Calculation), Moscow: Mashinostroenie, 1977.

Archard, J.F., Contact of Rubbing Surfaces, Brit. J. Appl. Phys., 1953, vol. 24, p. 981.

Rigin, D.A., Some Remarks on Wear with Slip, Tren. Iznos, 1992, vol. 13, no. 1, pp. 21–26.

Tabor, D., The Wear of Non-Metallic Materials: A Brief Review, Proceedings of the Third Leeds-Lyon Symposium on Tribology, 1976, pp. 3–10.

Kozyrev, Yu.P. and Sedakova, E.B., Determining the Permissible Loads in Friction by Means of the Empirical Wear Law, Vestn. Mashinostr., 2007, no. 6, pp. 44–46.

Ken’ko, V.M., Standardizing Frictional Test Methods for Plastics, Vestsi AN BSSR, 1980, no. 2, pp. 52–57.

Russian Patent Approval 2007108828.

Broek, D., Elementary Engineering Failure Mechanics, Dordrecht: Kluwer, 1978.

Bersten, V.A. and Egorov, V.M., Differential Scanning Calorimetry of Polymers, New York: Ellis Horwood, 1994.

Spravochnik po plasticheskim massam (Plastics Handbook), Kataev, V.M., Popov, V.A., and Sazhin, B.I., Ed., Moscow: Khimiya, 1975.

Bahadur, S., The Development of Transfer Films and Their Role in Polymer Tribology, Wear, 2000, vol. 245, pp. 92–99.

Gong, D., Physical Models of Adhesive Wear of Polytetrafluoroethylene and Its Composites, Wear, 1997, vol. 147, pp. 9–24.

Okhlopkova, A.A., Adrianova, O.A., and Popov, S.N., Modifikatsiya polimerov ul’tradispersnymi soedineniyami (Polymer Modification by Ultradisperse Compounds), Yakutsk: Izd. YaF SO RAN, 2003.

Author information

Authors and Affiliations

Additional information

Original Russian Text © Yu.P. Kozyrev, E.B. Sedakova, 2009, published in Vestnik Mashinostroeniya, 2009, No. 7, pp. 43–47.

This article forms part of a cycle on problems of tribology (friction, wear, and lubrication), edited by Yu.N. Drozdov of the Russian Academy of Astronautics.

About this article

Cite this article

Kozyrev, Y.P., Sedakova, E.B. Wear mechanisms of polytetrafluoroethylene and its composites. Russ. Engin. Res. 29, 674–677 (2009). https://doi.org/10.3103/S1068798X09070089

Published:

Issue Date:

DOI: https://doi.org/10.3103/S1068798X09070089