Abstract

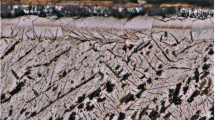

Boronizing (boron diffusion) is one of the treatments applied to improve the surface properties of steels. In this study, an interstitial-free (IF) steel was boronized and titanium diffused in order to gain knowledge about the diffusion mechanism. Boronizing was carried out electrothermochemically at 900°C by applying a current density of 0.10 or 0.40 A/cm2 for 45 or 120 minutes in a salt bath containing 100% Na2B4O7 while titanium diffusion was performed thermally at 1000°C for 2 hours. Single-layered diffusion coatings were formed by either boronizing or titanium diffusion whereas multi-layered diffusion coatings were generated by both boronizing and titanium diffusion. One part of the study was concerned with first boronizing and then titanium diffusion while a reverse sequence of the process, i.e. first titanium diffusion and then boronizing, was applied in the other part. The generated single-layered and multi-layered diffusion coatings were characterised by using an optical microscope, a scanning electron microscope equipped with an energy dispersive spectrometer, and an X-ray diffractometer. Occurrence of six chemical reactions during titanium diffusion was assumed and the standard formation enthalpies of these reactions were calculated by using a database. On investigating the microstructure, it was understood that both a boride layer and a titanium based diffusion layer were formed by first boronizing and then titanium diffusion. However, it was observed that the previously formed titanium based diffusion layer inhibited the diffusion of boron atoms in case of first titanium diffusion and then boronizing. On the other hand, if the duration of boronizing and the current density applied during this treatment that was carried out after titanium diffusion were increased, formation of boride phases, as well as of a titanium based diffusion layer, was achieved. The semi-quantitative atomic per cent chemical analyses carried out by the energy dispersive spectrometer and X-ray diffraction analyses pointed out the formation of metastable boride phase of Fe3B, as well as stable boride phases of Fe2B and FeB on the surface of the IF steel that was only boronized. It was concluded that the standard formation enthalpies of the six supposed chemical reactions were negative, indicating that these reactions could occur at a normal atmospheric pressure. In addition, most of the products of these reactions were detected in the X-ray diffraction analyses.

Similar content being viewed by others

References

Suwattananont, N., Multi-component boron coatings on low carbon steel AISI 1018, PhD Thesis, New Jersey: Inst. Technol., 2010.

Hayashi, Y. and Sugeno, T., Acta Metall., 1970, vol. 18, pp. 693–697.

Lucci, A. and Venturello, G., Scr. Metall., 1971, vol. 5, pp. 17–24.

Hayashi, Y. and Sugeno, T., Scr. Metall., 1971, vol. 5, pp. 25–26.

Brown, A., Garnish, J.D., and Honeycombe, R.W.K., Met. Sci., 1974, vol. 8, pp. 317–324.

Fichtl, W., Mater. Eng., 1981, vol. 2, pp. 276–286.

Sinha, A.K., Heat Treating: Boriding (Boronizing) of Steels, Materials Park, OH: ASM Int., 1995, vol. 4, pp. 978–997.

Jain, V. and Sundararajan, G., Surf. Coat. Technol., 2002, vol. 149, no. 1, pp. 21–26.

Yan, P.X., Zhang, X.M., Xu, J.W., Wu, Z.G., et al., Mater. Chem. Phys., 2001, vol. 71, pp. 107–110.

Asthana, P., Liang, H., Usta, M., and Ucisik, A.H., J. Tribol., 2006, vol. 129, no. 1, pp. 1–10.

Segers, L., Fontana, A., and Winand, R., Electrochim. Acta, 1991, vol. 36, no. 1, pp. 41–47.

Kartal, G., Boriding of metals via cathodic reduction and thermal diffusion method (CRTD–bor) and optimization of their production parameters, PhD Thesis, Istanbul: Inst. Sci. Technol., Istanbul Tech. Univ., 2011.

Goeuriot, P., Thevenot, F., Driver, J.H., and Magnin, T., Wear, 1983, vol. 86, no. 1, pp. 1–10.

Kessler, O.H., Hoffman, F.T., and Mayr, P., Surf. Coat. Technol., 1999, vols. 120–121, pp. 366–372.

Khodasevich, V.V., Solodukhin, I.A., Uglov, V.V., Hartmann, J., et al., Surf. Coat. Technol., 1998, vol. 98, nos. 1–3, pp. 1433–1436.

Sen, U., Mater. Des., 2005, vol. 26, pp. 167–174.

Ikeda, T. and Nakajima, H., Mater. Lett., 2004, vol. 58, pp. 3807–3811.

Radjabov, T.D., Iskanderova, Z.A., Iskanderov, A.Sh., Kamardin, A.I., et al., Surf. Coat. Technol., 1995, vol. 72, pp. 88–92.

Tal-Gutelmacher, E., Gemma, R., Pundt, A., and Kirchheim, M., Acta Mater., 2010, vol. 58, pp. 3042–3049.

Gidikova, N., Mater. Sci. Eng., A, 1997, vol. 222, no. 1, pp. 84–90.

IF (interstitial-free) steel. http://www.steel.org/en/ Autosteel_org/Web%20Root/Research/AHSS%20Data %20Utilization/IF.aspx. Accessed July 10, 2014.

Majumdar, S., Bhattacharjeeb, D., and Ray, K.K., Scr. Mater., 2011, vol. 64, pp. 288–291.

Bayraktar, E., Kaplan, D., Devillersb, L., and Chevalier, J.P., J. Mater. Process. Tech., 2007, vol. 189, pp. 114–125.

Duttaa, K. and Ray, K., Mater. Sci. Eng., A, 2013, vol. 575, pp. 127–135.

Davis, J.R., Surface Hardening of Steel: Understanding the Basics: Boriding, Materials Park, OH: ASM Int., 2002, pp. 213–226.

Choo, W.K. and Kaplow, R., Metall. Mater. Trans. A, 1977, vol. 8, no. 3, pp. 417–419.

Kartal, G., Kahvecioglu, O., and Timur, S., Surf. Coat. Technol., 2006, vol. 200, pp. 3590–3593.

Timur, S., Kartal, G., Eryilmaz, O.L., and Erdemir, A., US Patent 2010/00186111, 2010.

Sen, U. and Sen, S., Mater. Charact., 2003, vol. 50, pp. 261–267.

Sen, U., Sen, S., Koksal, S. and Yilmaz, F., Mater. Des., 2005, vol. 26, pp. 175–179.

Sen, U., Sen, S., and Yilmaz, F., J. Mater. Process. Techol., 2004, vol. 148, pp. 1–7.

Kartal, G., Eryilmaz, O.L., Krumdick, G., Erdemir, A., et al., Appl. Surf. Sci., 2011, vol. 257, pp. 6928–6934.

Zhou, J. and Bai, P., Asia-Pac. J. Chem. Eng., 2015, vol. 10, pp. 325–338.

Çelikkan, H., Öztürk, M.K., Aydin, H., and Aksu, M.L., Thin Solid Films, 2007, vol. 515, pp. 5348–5352.

Kilic, A., Kartal, G., Urgen, M., and Timur, S., Surf. Eng. Appl. Electrochem., 2013, vol. 49, no. 2, pp. 168–175.

Kahvecioglu, O., Sista, V., Eryilmaz, O.L., Erdemir, A., et al., Thin Solid Films, 2011, vol. 520, pp. 1575–1581.

Kaptay, G. and Kuznetsov, S.A., Plasmas Ions, 1999, vol. 2, pp. 45–56.

Material Safety Data Sheet, ID: C1–103, Ammonium Chloride, Houston, TX: Chem. One, 2010.

Mitsubishi Safety Chemical Institute, OECD SIDS Initial Assessment Report for SIAM 17, Ammonium Chloride, Arona, 2004.

Becht, J.G.M., van Der Put, P.J., and Schoonman, J., Eur. J. Sol. State Inorg. Chem., 1989, vol. 26, no. 4, pp. 401–412.

Bram, M., Aubertin, F., Venskutonis, A., and Breme, J., Mater. Sci. Eng., A, 1999, vol. 264, pp. 74–80.

The periodic table of elements (including atomic radius). http://www.sciencegeek.net/tables/Atomic-Radius.pdf. Accessed February 8, 2016.

Author information

Authors and Affiliations

Corresponding author

Additional information

The article is published in the original.

About this article

Cite this article

Şeşen, F.E., Özgen, Ö.S. & Şeşen, M.K. Effect of process parameters on the formation of boron-titanium and titanium-boron multi-layered diffusion coatings on interstitial-free steel. Surf. Engin. Appl.Electrochem. 53, 167–178 (2017). https://doi.org/10.3103/S1068375517020107

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.3103/S1068375517020107