Abstract

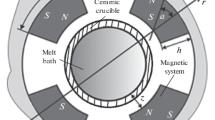

The problem of increasing the efficiency of melt mixing in a furnace bath or mixer at low melt levels using an electromagnetic mixer installed on the furnace or mixer side is considered. It is proposed to use a transverse magnetic flux mixer as an electromagnetic mixer. A comparative analysis of devices with a longitudinal and transverse running magnetic field is performed. To perform the comparative analysis, mathematical modeling is carried out using the ANSYS software. By means of parametric mathematical models of electromagnetic mixers with a longitudinal and transverse magnetic field installed on the mixer side, it is possible to accurately reflect electromagnetic processes and obtain dependences of electromagnetic forces in the melt, to determine the release of thermal power in the melt and inductor, and power consumption and cosφ for different linear current load and different melt levels in the mixer. Based on the results of mathematical modeling, two types of electromagnetic mixers are compared and best practice advices are provided for choosing the mixer type depending on the initial metallurgical process conditions.

Similar content being viewed by others

REFERENCES

Kalnin’, T.K., Lineinye induktsionnye mashiny s poperechnym magnitnym potokom (Linear Induction Machines with Transverse Magnetic Flux), Riga: Zinatne, 1980.

Nasar, S.A. and Del Cid, L., Jr., Propulsion and levitator forces in a single-sided linear induction motor for high-speed ground transportation, Proc. IEEE, 1973, vol. 61, no. 5, pp. 638–644.

Vol’dek, A.I., Induktsionnye magnitogidrodinamicheskie mashiny s zhidkometallicheskim rabochim telom (Induction Magnetohydrodynamic Machines with Liquid Metal Working Fluid), Leningrad: Energiya, 1970.

Svenchanskii, A.D., Elektricheskie promyshlennye pechi. Chast’ 1. Elektricheskie pechi soprotivleniya (Electrical Industrial Furnaces, Part 1: Resistance Furnace), Moscow: Energiya, 1975.

Isidorov, E., US Patent 8 486 326, Byull. Izobret., 2013, no. 7.

Zienkiewicz, O., The Finite Element Method in Engineering Science, New York: McGraw-Hill, 1971.

Timofeev, V.N., Avdulov, A.A., Avdulova, Yu.S., Boyakov, S.A., and Khomenkov, P.A., RF Patent 2543022, Byull. Izobret., 2015, no. 2.

Author information

Authors and Affiliations

Corresponding author

Additional information

Translated by A. Kolemesin

About this article

Cite this article

Avdulova, Y.S., Boyakova, T.A. & Avdulov, A.A. Effective Metal Mixing at a Low Melt Level in a Furnace or Mixer. Russ. Electr. Engin. 91, 286–291 (2020). https://doi.org/10.3103/S1068371220040021

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.3103/S1068371220040021