Abstract—

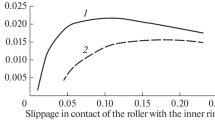

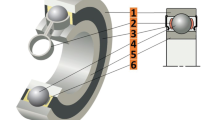

Conditions for seizing during hydrodynamic contact between parts under rolling friction have been studied. For this purpose, a known friction model based on the generalized Eyring equation and taking into account the phenomenon of oil film self-heating has been used. The fact that a correct description of friction curves using this model is possible has been confirmed by comparison with published experimental data. Conditions are revealed, under which in the thermal zone of friction curves, despite a decrease in the friction coefficient, an increase in friction power loss continues. It is shown that the bearing seizing hazard occurs when the bearings operate in a thermal zone of the friction curves. A concept of critical slide–roll ratio that represents a boundary of the thermal zone of friction curves has been introduced, and its dependence on the contact pressure and temperature has been studied for PAO1 grade polyalphaolefin oil in the temperature range of 40–100°C and for MN-7.5u grade oil in the range of 60−140°C. It is shown that the critical sliding-to-rolling ratio increases with decreasing contact pressure in the bearing, as well as with increasing oil temperature. It is concluded that the conditions of contact between the rollers and the inner ring promote an increase in friction power loss to a greater extent than the conditions of contact between the rollers and the outer ring. This indicates a higher seizing hazard in the case of the inner ring than in the case of the outer ring, which is confirmed by the statistics of rolling bearing failures. In order to prevent seizing in bearings, it is necessary to provide a margin with respect to critical sliding at the bearing design stage.

Similar content being viewed by others

REFERENCES

Gan, K.G., Method for calculating the minimum allowable load in high-speed lightly loaded rolling bearings, Vestn. MGTU, Ser. Mashinostr., 1994, no. 1, pp. 32–38.

Muraki, M., EHL traction and related rheological parameters under high temperature conditions, J. Synth. Lubric., 1992, vol. 9, no. 1, pp. 29–43.

Muraki, M., Molecular structure of synthetic hydrocarbon oils and their rheological properties governing traction characteristics, Tribol. Int., 1987, vol. 20, no. 6, pp. 347–354.

Zhang, J., Tan, A., and Spikes, H., Effect of base oil structure on elastohydrodynamic friction, Tribol. Lett., 2017, vol. 65, no. 1, pp. 1–24.

Vengudusamy, B., Enekes, C., and Spallek, R., EHD friction properties of ISO VG20 gear oils with smooth and rough surfaces, Friction, 2020, vol. 8, no. 1, pp. 164–181.

Archard, J.F. and Baglin, K.P., Nondimensional presentation of frictional tractions in elastohydrodynamic lubrication. Part I: Fully flooded conditions, ASME J. Lubric. Technol., 1975, vol. 97, no. 3, pp. 398–410.

Baskin, E.M., Power bearing life equations for various lubrication conditions, Probl. Mashinostr. Nadezhnosti Mashin, 1993, no. 5, pp. 57–64.

Ivanov, B.A., Evaluation of the anti-seize resistance of rolling bearing units at high speeds, in Dinamika i prochnost' mekhanicheskikh sistem (Dynamics and Strength of Mechanical Systems), Perm: PPI, 1982, pp. 3–6.

Morales-Espejel, G.E. and Gabelli, A., Rolling bearing seizure and sliding effects on fatigue life, Proc. Inst. Mech. Eng., 2019, vol. 233, no. 2, pp. 339–354.

LaFountain, A.R., Johnston, G.J., and Spikes, H.A., The elastohydrodynamic traction of synthetic base oil blends, Tribol. Trans., 2001, vol. 44, no. 4, pp. 648–656.

Spikes, H. and Jie, Z., History, origins and prediction of elastohydrodynamic friction, Tribol. Lett., 2014, vol. 56, pp. 1–25.

Spikes, H., Basics of EHL for practical application, Lubric. Sci., 2015, vol. 27, no. 1, pp. 45–67.

Korolev, A.A. and Korolev, A.V., Influence of geometrical parameters of the working surface of the bearing raceway on its operability, J. Frict. Wear, 2015, vol. 36, no. 2, pp. 189–192.

Balyakin, V.B. et al., Teoriya i proektirovanie opor rotorov aviatsionnykh GTD (Theory and Design of Rotor Bearings for Aircraft Gas Turbine Engines), Samara: Izd. SGAU im. akad. S.P. Koroleva, 2007.

Author information

Authors and Affiliations

Corresponding author

Additional information

Translated by O. Polyakov

About this article

Cite this article

Klebanov, I.M., Moskalik, A.D. & Brazhnikova, A.M. Critical Sliding in Rolling Bearings under Hydrodynamic Friction Conditions. J. Frict. Wear 43, 255–261 (2022). https://doi.org/10.3103/S1068366622040067

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.3103/S1068366622040067