Abstract

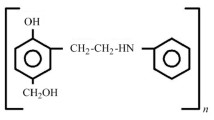

Half-metallic composite brake pads for railroad cars have polymeric designs with metal elements exposed to corrosive attack. Model electrolytes obtained from potential products of interaction with the pad during storage and operation are used as samples in studying the corrosion rate kinetics in the metal parts of the pads.

Similar content being viewed by others

References

Shiryaev, B.A., Proizvodstvo tormoznykh zheleznodorozhnykh kolodok iz kompozitsionnykh materialov dlya zheleznodorozhnykh vagonov (Production of Railway Brake Shoes from Composite Materials for Railway Coaches), Moscow: Khimiya, 1982.

Mantsev, S.V., Peshkova, A.F., and Zaitseva, N.N., Graphite application as composite material filler for railway brake shoes, Kauchuk Rezina, 1979, no. 9, pp. 35–37.

Larin, T.V., Paryshev, Yu.M., and Uzlov, I.G., Ways of further increasing of solid-rolled wheel quality, Zheleznodor. Transp., 1973, no. 2, p. 56.

Larin, T.V., Vekser, N.A., and Devyatkin, V.P., On choice of steel for railway wheels at high-speed motion, Vestn. Vseross. Nauch.-Issl. Inst. Zheldor. Transp., 1968, no. 6, pp. 35–38.

Vukolov, L.A. and Inozemtsev, V.G., Issledovanie i ekspluatatsiya kompozitsionnykh tormoznykh kolodok na vagonakh. Ser. “Vagony i vagonnoe khozyaistvo”. Vyp. 50 (Study and Exploitation of Composite Brake Shoes on Coaches. Ser. “Coaches and Coach Industry”, No. 50), Moscow: NIITEI MPS, 1969.

Vukolov, L.A., Shpadi, D.V., Nalev, I.A., et al., New brake wheel-preserving shoes for rolling-stock, Vestn. Vseross. Nauch.-Issl. Inst. Zheldor. Transp., 2011, no. 1, pp. 38–42.

Astashkevich, B.M., Features and kinetics of origin of secondary structure on surfaces of railway brake shoes made of phosphor cast iron, J. Fric. Wear, 1998, vol. 19, pp. 63–72.

Astashkevich, B.M. and Chaikovskii, K.R., Production of inoculated friction cast iron for brake blocks, Litein. Proizv., 1993, no. 7, pp. 8–9.

Voronchikhin, A.I., Nalev, I.A., Bychkov, V.N., Vukolov, L.A., Naishev, A.A., and Simonova, T.S., RF Patent 2340805, 2007.

Zhuk, N.P., Kurs korrozii i zashchity metallov (Course of Corrosion and Defense of Metals), Moscow: Metallurgiya, 1976.

Author information

Authors and Affiliations

Corresponding author

Additional information

Original Russian Text © A.V. Pavlov, S.P. Kudelnikova, A.N. Vicharev, 2015, published in Trenie i Iznos, 2015, Vol. 36, No. 2, pp. 161–166.

About this article

Cite this article

Pavlov, A.V., Kudelnikova, S.P. & Vicharev, A.N. On the corrosion resistance of half-metallic composite brake pads for railroad cars. J. Frict. Wear 36, 123–126 (2015). https://doi.org/10.3103/S1068366615020130

Received:

Published:

Issue Date:

DOI: https://doi.org/10.3103/S1068366615020130