Abstract

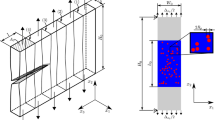

The effect of the internal (interparticle) and external friction on the limiting state generation has been analyzed in terms of the shear-induced failure criterion of the surface layers in the compacted disperse materials. The proposed design scheme based on the Mohr-Coulomb combined diagram has made it possible to develop an original method and derive analytic dependences for determining the normal and tangential stresses in the interlayer shear sites along with the orientation angles of these sites. It has been shown that, with increasing coefficient of external friction, the pressure in the interlayer shear sites reduces until tensile stresses are generated. This is accompanied by the nucleation of the crack at a right angle close to the side surface perpendicular of the formed item.

Similar content being viewed by others

References

Briscoe, B.J. and Adams, M.J., Tribology in Particulate Technology, Bristol: Adam Higler, 1987.

Heift, R., Cisnieniowa aglomeracja materialow roslinnych, (Agglomeration of Vegetable Materials under Pressure) Bialystok: Politechnika Bialostocka, Instytut Technologii Eksploatacji w Radomiu, 2002.

Roman, O.V. and Gabrielov, I.P., Spravochnik po poroshkovoi metallurgii: poroshki, materialy, protsessy (Handbook on Powder Metallurgy: Powders, Materials, Processes), Minsk: 1988.

Barsukov, V.G. and Krupich, B., Tribomekhanika Dispersnykh materialov. Tekhnologicheskie prilozheniya (Tribomechanics of Dispersed Materials. Thechnological Applications) Grodno: Grodn. Gos. Univ., 2004.

Stanley-Wood, N.G., Uniaxial powder compaction, in Tribology in Particulate Technology, Briscoe, B.J. and Adams, M.J., Bristol: Adam Higler, 1987, pp. 249–272.

Klyachko, L.I., Umanskii, A.M., and Bobrov, V.N., Oborudovanie i osnastka dlya formovaniya poroshkovykh materialov (Equipment and Accessory for Powder Material Formation), Moscow: Metallurgiya, 1986.

Kiparisov, S.S. and Padalko, O.V., Oborudovanie predpriyatii poroshkovoi metallurgii (Equipment of Powder Metallurgy Plants), Moscow: Metallurgiya, 1988.

Barsukov, V.G., Krupich, B., and Barsukov, V.V., The effect of interparticulate and external friction on the orientation of shear planes when brittle dispersed materials undergo compaction, J. Fric. Wear, 2012, vol. 33, pp. 53–59.

Barsukov, V.G., Barsukov, V.V., and Krupich, B., Determination of shift areas in deformed disperse materials taking into account interparticle and external friction by More stress method, Mekh. Mashin, Mekhan. Mater., 2013, vol. 22, pp. 71–75.

Smith, G.N., Elements of Soil Mechanics for Civil and Mining Engineers, London: Granada, 1982.

Author information

Authors and Affiliations

Corresponding author

Additional information

Original Russian Text © V.G. Barsukov, B. Krupicz, V.V. Barsukov, 2015, published in Trenie i Iznos, 2015, Vol. 36, No. 2, pp. 147–153.

About this article

Cite this article

Barsukov, V.G., Krupicz, B. & Barsukov, V.V. Tribomechanical analysis of interlayer shear and surface crack nucleation processes in compacted disperse materials. J. Frict. Wear 36, 112–117 (2015). https://doi.org/10.3103/S1068366615020026

Received:

Published:

Issue Date:

DOI: https://doi.org/10.3103/S1068366615020026