Abstract

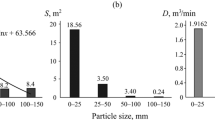

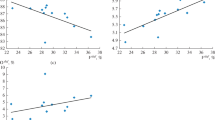

Traditional concepts regarding the influence of the entrainment of coal particles in coking on the quality of coal tar may usefully be expanded. In addition to increase in the ash content, the water content of the tar is increased. To eliminate stabilization of the emulsion forming in the condensation department, a limit of 10–13% has been imposed on the content of coal in the ≤0.2 mm class. Analysis of production data shows that the presence of coal particles smaller than 0.071 mm in the batch increases the density of the coal tar and its content of quinoline-insoluble materials. It is found that the water content of the tar is increased more strongly by the aromatic component of the coal than by the mineral component. The emulsifying properties of dusty coal are greatest for Zh coal and least for G coal.

Similar content being viewed by others

REFERENCES

Golovko, M.B., Miroshnichenko, D.V., and Kaftan, Yu.S., Predicting the coke yield and basic coking byproducts: an analytic review, Coke Chem., 2011, vol. 54, no. 9, pp. 331–338.

Miroshnichenko, D.V., Drozdnik, I.D., Kaftan, Yu.S., and Desna, N.A., Oxidation of Pokrovskoe coal in laboratory and natural conditions. 1. Kinetics of oxidation and technological properties, Coke Chem., 2015, vol. 58, no. 3, pp. 79–87.

Miroshnichenko, D.V. and Ulanovskii, M.L., Compositions of coals and anthracites as bases for modeling their properties, Koks Khim., 2003, no. 4, pp. 3–7.

Miroshnichenko, D.V., Drozdnik, I.D., Kaftan, Yu.S., Bidolenko, N.B., and Desna, N.A., Coking of coal bath different content of oxidized coal, Coke Chem., 2012, vol. 55, no. 5, pp. 155–164.

Miroshnichenko, D.V. and Golovko, M.B., Predicting the yield of coke and its byproducts on the basic of elementary and petrographic analysis: an analytic review, Coke Chem., 2014, vol. 57, no. 3, pp. 117–128.

Nazarov, V.G., Removal of naphthalene and tar from coke–oven gas in primary cooling and condensation, Coke Chem., 2016, vol. 59, no. 6, pp. 221–234.

Naumov, V.N., Malov, V.A., Eron’ko, O.N., and Bibik, E.E., Poverkhnostnye yavleniya i dispersnye sistemy: uchebnoe posobie dlya studentov zaochnogo otdeleniya (Surface Phenomena and Disperse Systems: Manual for Vocational Education Students), St. Petersburg: S.-Peterb. Gos. Tekhnol. Inst., 2007.

Pasternak, A.A., Bannikov, L.P., Skripchenko, N.P., et al., Formation technology of direct emulsions with derivatives of coal tar, Uglekhim. Zh., 2016, no. 1, pp. 7–12.

Pasternak, A.A., Bannikov, L.P., Nesterenko, S.V., and Smirnova, A.V., Production of direct emulsions based on coal tar, Uglekhim. Zh., 2016, no. 2, pp. 17–23.

Ding, L., Investigation of bituminous coal hydrophobicity and its influence on flotation, Energy Fuels, 2009, vol. 23, no. 11, pp. 5536–5543.

Wang, J., He, Y., Yang, Y., et al., Research on quantifying the hydrophilicity of leached coals by FTIR spectroscopy, Physicochem. Probl. Miner. Process., 2017, vol. 53, no. 1, pp. 227–239.

Usanina, A.S. and Patrakov, Yu.F., Experimental evaluation of the wetting properties of the coal surface, Gorn. Inf.-Anal. Byull., 2013, no. 6, pp. 208–212.

Usanina, A.S., Arkhipov, V.A., Paleev, D.Yu., and Patrakov, Yu.F., The influence of the chemical composition of coal on the wettability of their surface, Vestn. Kuzbass. Gos. Tekh. Univ., 2011, no. 3, pp. 101, 102.

Holushko, M.E. and Mastalerz, M.D., Coal maceral chemistry and its impication for selectivity in coal floatability, Int. J. Coal Prep. Util., 2015, vol. 35, pp. 99–110.

Issledovanie, razrabotka i vnedreni novykh metodov obezvozhivaniya i obezzolivaniya kamennougol’noi smoly: otchet po NIR (Analysis, Development, and Implementation of New Methods of Dewatering and Desalting of Coal Tar: The Results of Scientific Research Work), Kharkov: Ukr. Gos. Nauchno-Issled. Uglekhim. Inst., 1971, no. 5380.

Nakagawa, T., Carbon deposition in coke oven chamber: Influence of fine particles on formation rate of carbon deposits, Nippon Steel Tech. Rep., 2006, no. 7, pp. 63–68.

Ovcharenko, F.D., Gidrofil’nost’ glin i glinistykh materialov (Hydrophilicity of Clay and Clay Materials), Kiev: Akad. Nauk UkrSSR, 1961.

Novyi spravochnik khimika i tekhnologa. Syr’e i produkty promyshlennosti organicheskikh i neorganicheskikh veshchestv (New Handbook for Chemist-Technologist: Raw Materials and Industrial Products of Organic and Inorganic Substances), St. Petersburg: Mir i Sem’ya, 2002, part 1.

TU (Industrial Standard) U 24.1-00190443-005:2009: Electrode Coal-Tar Pitch, Pokrovsk: Makeevkoks, 2009.

Laskowski, J.S., Surface chemistry fundamentals in fine coal processing, in The Coal Handbook: Towards Cleaner Production, Woodhead Publishing Series in Energy vol. 1, Amsterdam: Elsevier, 2013, ch. 12, pp. 347–421.

Author information

Authors and Affiliations

Corresponding authors

Additional information

Translated by Bernard Gilbert

About this article

Cite this article

Bannikov, L.P., Miroshnichenko, D.V., Nesterenko, S.V. et al. Influence of Small Coal Particles in Coking Batch on Coal-Tar Quality. Coke Chem. 62, 95–102 (2019). https://doi.org/10.3103/S1068364X19030025

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.3103/S1068364X19030025