Abstract

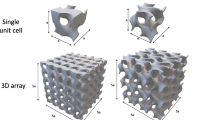

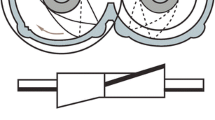

Approximate comparison of the pressure parameters for metallurgical coke in molding systems may be based on the residence time of the coal mass (density >900 kg/m3) under pressure. Caterpillar-type molding systems yield industrial productivity levels, but reconstruction with increase in the block height of the plastic coal mass to 0.19–0.25 m is expedient. It is shown for the first time that coal block of height 0.3 m may be supplied to the roller press in screw-type molding systems. This permits the creation of high-technology double-screw molding systems with productivity at industrial levels.

Similar content being viewed by others

References

Florinskii, N.V. and Matskevich, D.D., Pilot Production System for Shaped Metallurgical Coke, Koks Khim., 1989, no. 4, pp. 16–18.

Toryanik, E.I., Shmadchenko, V.N., Shul’ga, I.V., et al., Residence Time of Plastic Mass in Molding Machine and Quality of Shaped Coke, Koks Khim., 1990, no. 10, pp. 18–19.

Tyutyunnikov, Yu.B., Vasil’ev, V.S., Reva, A.S., et al., Reshaping Plastic Coal Blocks in Roller Presses, Metallurgiya i koksokhimiya (Metallurgy and Coke Chemistry), Kiev: Tekhnika, 1981, issue 73, pp. 43–46.

Vasil’ev, V.S., Raschet parametrov val’tsovykh pressov v protsesse proizvodstva formovannogo koksa (Calculation of Roller-Press Parameters in Shaped-Coke Production), Slavyansk: Pechatnyi Dvor, 2008.

Speranskaya, G.V., Tyutyunnikov, Yu.B., et al., Nauchnye osnovy proizvodstva formirovannogo metallurgicheskogo koksa iz slabospekayushchikhsya uglei (Scientific Principles for the Production of Shaped Metallurgical Coke from Poorly Clinkering Coal), Moscow: Metallurgiya, 1987.

Shchukin, P.A. and Sychev, V.S., Using Roller Presses to Shape Coals Heated to the Plastic State, Novye metody podgotovki i koksovaniya uglei (New Methods of Coal Preparation and Coking), Moscow: Nauka, 1964, pp. 97–103.

Tyutyunnikov, Yu.B. and Vasil’ev, V.S., Analysis of the Deformation of Plastic Coal Mass in Roller Presses, Koks Khim., 1989, no. 3, pp. 16–17.

Tyutyunnikov, Yu.B., Vasil’ev, V.S., and Zhazhin, S.N., Pressure Applied to Plastic Coal Mass in Roller Presses, Koks Khim., 1987, no. 12, pp. 19–22.

Tyutyunnikov, Yu.B. and Vasil’ev, V.S., Calculation of Molding-System Parameters, Metallurgiya i koksokhimiya (Metallurgy and Coke Chemistry), Kiev: Tekhnika, 1986, issue 91, pp. 126–129.

Toryanik, E.I., Sheptovitskii, M.S., Shmadchenko, V.N., et al., Industrial Trials of Shaped-Coke Production from Poorly Clinkering Donetsk Basin Coal, Koks Khim., 1985, no. 9, pp. 20–24.

Toryanik, E.I., Shul’ga, I.V., Shmadchenko, V.N., and Minenko, E.V., Nonsteady Model of the Flow of Plastic Coal Mass, Koks Khim., 1991, no. 9, pp. 19–21.

Shul’ga, I.V., Toryanik, E.I., Lur’e, M.V., et al., Rational Batch Shaping with Increased Participation of TCoal, Koks Khim., 1989, no. 11, pp. 15–18.

Litvin, E.M. and Popov, A.I., Shaping Hot Batch in Various Molding Systems, Koks Khim., 1988, no. 5, pp. 14–17.

Toryanik, E.I. and Sheptovitskii, M.S., More Effective Production of Shaped Coke, Koks Khim., 1990, no. 6, pp. 51–53.

Nefedov, P.Ya., Litvin, E.M., Azimov, A.A., et al., Shaping of Hot Coal in a Double-Screw Molding System with Ultrasound, Koks Khim., 1975, no. 11, pp. 13–17.

Tyutyunnikov, Yu.B., Vasil’ev, V.S., and Lur’e, M.V., Calculation of Roller-Press Parameters, Koks Khim., 1980, no. 3, pp. 8–9.

Semchuk, V.V. and Vasil’ev, V.S., USSR Inventor’s Certificate 765017, Byull. Izobret., 1980, no. 35.

Author information

Authors and Affiliations

Additional information

Original Russian Text © V.S. Vasil’ev, 2011, published in Koks i Khimiya, 2011, No. 4, pp. 32–38.

About this article

Cite this article

Vasil’ev, V.S. Coke-molding systems. Coke Chem. 54, 123–128 (2011). https://doi.org/10.3103/S1068364X11040065

Received:

Published:

Issue Date:

DOI: https://doi.org/10.3103/S1068364X11040065