Abstract

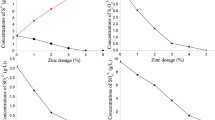

This study investigates the removal of sulfur from high-sulfur bauxite via zinc addition during the Bayer process. The results show that \({{{\text{S}}}_{{\text{2}}}}{\text{O}}_{{\text{3}}}^{{2 - }}\), \({\text{SO}}_{{\text{3}}}^{{2 - }}\), and \({\text{SO}}_{{\text{4}}}^{{2 - }}\) are first reduced to S2–, and after adding zinc, the S2– enters into the red mud in the form of ZnS. So, the different valence sulfur states (S2–, \({{{\text{S}}}_{{\text{2}}}}{\text{O}}_{{\text{3}}}^{{2 - }}\), \({\text{SO}}_{{\text{3}}}^{{2 - }}\), and \({\text{SO}}_{{\text{4}}}^{{2 - }}\)) in the sodium aluminate solution can be effectively removed by adding zinc during the digestion process. The kinetics analysis results indicate that the apparent activation energy is 10.546 kJ/mol, and sulfur removal is controlled by the internal diffusion of the solid film. Increasing the temperature, time, and zinc concentration and decreasing the bauxite particle size are beneficial to the removal of sulfur. This is a new and effective method of sulfur removal by adding zinc during the digestion process, and a reasonable process of alumina production from high-sulfur bauxite is developed and described. The results shed some light on the removal of sulfur from high-sulfur bauxite during the alumina production.

Similar content being viewed by others

REFERENCES

Gu, F.Q., Li, G.H., Peng, Z.W., Luo, J., Deng, B.N., Rao, M.J., Zhang, Y.B., and Jiang, T., Upgrading diasporic bauxite ores for iron and alumina enrichment based on reductive roasting, JOM, 2018, vol. 70, no. 9, pp. 1893–1901.

Liu, Z.W., Yan, H.W., and Ma, W.H., Sulfur removal of high-sulfur bauxite, Min., Metall. Explor., 2020, vol. 37, no. 5, pp. 1617–1626.

Han, G.H., Su, S.P., Huang, Y.F., Peng, W.J., Cao, Y.J., and Liu, J.T., An insight into flotation chemistry of pyrite with isomeric xanthates: A combined experimental and computational study, Minerals, 2018, vol. 8, no. 4, pp. 1–16.

Abikenova, G.K., Kovzalenko, V.A., Ambarnikova, G.A., and Ibragimov, A.T., Investigation of the effect and behavior of sulfur compounds on the technological cycle of alumina production, Russ. J. Non-Ferrous Met., 2008, vol. 49, no. 2, pp. 91–96.

Lou, Z.N., Xiong, Y., Feng, X.D., Shan, W.J., and Zhai, Y.C., Study on the roasting and leaching behavior of high-sulfur bauxite using ammonium bisulfate, Hydrometallurgy, 2016, vol. 165, pp. 306–311.

Hu, X.L., Chen, W.M., and Xie, Q.L., Desulfuration of high sulfur bauxite by oxidation roasting, J. Cent. South Univ. Sci. Technol., 2010, vol. 41, no. 3, pp. 852–858.

Lu, D., Lv, G.Z., Zhang, T.A., Zhang, W.G., Wang, L., and Wang, Y.X., Roasting pre-treatment of high-sulfur bauxite for sulfide removal and digestion performance of roasted ore, Russ. J. Non-Ferrous Met., 2018, vol. 59, no. 5, pp. 493–501.

Chimonyo, W., Corin, K.C., Wiese, J.G., and O’Connor, C.T., Redox potential control during flotation of a sulphide mineral ore, Miner. Eng., 2017, vol. 110, pp. 57–64.

Bulut, G., Arslan, F., and Atak, S., Flotation behaviors of pyrites with different chemical compositions, Miner. Metall. Process., 2004, vol. 21, no. 2, pp. 86–92.

Owusu, C., Quast, K., and Addai-Mensah, J., The use of canola oil as an environmentally friendly flotation collector in sulphide mineral processing, Miner. Eng., 2016, vol. 98, pp. 127–136.

Taguta, J., O’Connor, C.T., and McFadzean, B., The effect of the alkyl chain length and ligand type of thiol collectors on the heat of adsorption and floatability of sulphide minerals, Miner. Eng., 2017, vol. 110, pp. 145–152.

Awe, S.A., Sundlcvist, J.E., and Sandstrom, A., Formation of sulphur oxyanions and their influence on antimony electrowinning from sulphide electrolytes, Miner. Eng., 2013, vol. 53, pp. 39–47.

Gong, X.Z., Wang, Z., Zhuang, S.Y., Wang, D., Wang, Y.H., and Wang, M.Y., Roles of electrolyte characterization on bauxite electrolysis desulfurization with regeneration and recycling, Metall. Mater. Trans. B, 2017, vol. 48, no. 1, pp. 726–732.

Helms, H., Schlomer, E., and Jansen, W., Oscillation phenomena during the electrolysis of alkaline sulfide solutions on platinum electrodes, Monatsh. Chem., 1998, vol. 129, nos. 6–7, pp. 617–623.

Gong, X.Z., Wang, Z., Zhao, L.X., Zhang, S., Wang, D., and Wang, M.Y., Competition of oxygen evolution and desulfurization for bauxite electrolysis, Ind. Eng. Chem. Res., 2017, vol. 56, no. 21, pp. 6136–6144.

Marini, S., Salvi, P., Nelli, P., Pesenti, R., Villa, M., Berrettoni, M., Zangari, G., and Kiros, Y., Advanced alkaline water electrolysis, Electrochim. Acta, 2012, vol. 82, pp. 384–391.

Blight, K., Ralph, D.E., and Thurgate, S., Pyrite surfaces after bio-leaching: a mechanism for bio-oxidation, Hydrometallurgy, 2000, vol. 58, pp. 227–237.

Sun, J., Dai, X.H., Liu, Y.W., Peng, L., and Ni, B.J., Sulfide removal and sulfur production in a membrane aerated biofilm reactor: Model evaluation, Chem. Eng. J., 2017, vol. 309, pp. 454–462.

Wen, S.L., Hu, K.Q., Chen, Y.C., and Hu, Y.Y., The effects of Fe2+ on sulfur-oxidizing bacteria (SOB) driven autotrophic denitrification, J. Hazard. Mater., 2019, vol. 373, pp. 359–366.

Cheng, Y.Q., Chen, Y.L., Lu, J.C., Nie, J.X., and Liu, Y., Fenton treatment of bio-treated fermentation-based pharmaceutical wastewater: removal and conversion of organic pollutants as well as estimation of operational costs, Environ. Sci. Pollut. Res., 2018, vol. 25, no. 12, pp. 12083–12095.

Viviantira, E., Wan, C.L., Wong, B.T., and Lee, D.J., Denitrifying sulfide removal 16 with methanogenic culture, J. Taiwan Inst. Chem. Eng., 2012, vol. 43, no. 3, pp. 374–385.

Liu, Z.W., Li, D.Y., Ma, W.H., Yan, H.W., Xie, K.Q., Zheng, L.C., and Li, P.F., Sulfur removal by adding aluminum in the bayer process of high-sulfur bauxite, Miner. Eng., 2018, vol. 119, pp. 76–81.

Safarzadeh-Amiri, A., Walton, J., Mahmoud, I., and Sharifi, N., Iron(III)-polyphosphates as catalysts for the liquid redox sulfur recovery process, Appl. Catal., B, 2017, vol. 207, pp. 424–428.

Liu, Z.W., Ma, W.H., Yan, H.W., Xie, K.Q., Li, D.Y., Zheng, L.C., and Li, P.F., Sulfur removal with active carbon supplementation in digestion process, Hydrometallurgy, 2018, vol. 179, pp. 118–124.

Letícia, P.D.M., Patrícia, F.C., Mariana, M., Paula, C.S.G., Silvana, D.Q.S., Leandro, V.A.G., and Mônica, C.T., Simultaneous removal of sulfate and arsenic using immobilized nontraditional SRB mixed culture and alternative low-cost carbon sources, Chem. Eng. J., 2018, vol. 334, pp. 1630–1641.

Li, X.B., Li, C.Y., Peng, Z.H., Liu, G.H., Zhou, Q.S., and Qi, T.G., Interaction of sulfur with iron compounds in sodium aluminate solutions, Trans. Nonferrous Met. Soc. China, 2015, vol. 25, no. 2, pp. 608–614.

Kuznetsov, S.I., Grachev, V.V., and Tyurin, N.G., Interaction of iron and sulfur in alkaline aluminate solutions, Zh. Prikl. Khim., 1975, vol. 48, no. 4, pp. 748−750.

Li, X.B., Niu, F., Tan, J., Liu, G.H., Qi, T.G., Peng, Z.H., and Zhou, Q.S., Removal of S2− ion from sodium aluminate solutions with sodium ferrite, Trans. Nonferrous Met. Soc. China, 2016, vol. 26, no. 5, pp. 1419–1424.

Dixon, D.G. and Long, H., Pressure oxidation of pyrite in sulfuric acid media: a kinetic study, Hydrometallurgy, 2004, vol. 73, pp. 335–349.

Choi, A.E.S., Roces, S., Dugos, N., Futalan, C.M., Lin, S.S., and Wan, M.W., Optimization of ultrasound-assisted oxidative desulfurization of model sulfur compounds using commercial ferrate (VI), J. Taiwan Inst. Chem. Eng., 2014, vol. 45, no. 6, pp. 2935–2942.

Podkrajsek, B., Grgic, I., and Tursic, J., Determination of sulfur oxides formed during the S(IV) oxidation in the presence of iron, Chemosphere, 2002, vol. 49, no. 3, pp. 271–277.

Liu, Z.W., Li, W.X., Ma, W.H., Yin, Z.L., and Wu, G.B., Conversion of sulfur by wet oxidation in the Bayer process, Metall. Mater. Trans. B, 2015, vol. 46, no. 4, pp. 1702–1708.

Zhou, X.J., Yin, J.G., Chen, Y.L., Xia, W.T., Xiang, X.Y., and Yuan, X.L., Simultaneous removal of sulfur and iron by the seed precipitation of digestion solution for high-sulfur bauxite, Hydrometallurgy, 2018, vol. 181, pp. 7–15.

Wang, D.L., Light Metal Metallurgical Analysis, Beijing: Metallurgical Industry Press, pp. 67–69.

Pandey, S.K., Pandey, S., Parashar, V., Yadav, R.S., Mehrotra, G.K., and Pandey, A.C., Bandgap engineering of colloidal zinc oxysulfide via lattice substitution with sulfur, Nanoscale, 2014, vol. 6, no. 3, pp. 1602–1606.

Bendikov, T.A., Yarnitzky, C., and Licht, S., Energetics of a zinc–sulfur fuel cell, J. Phys. Chem. B, 2002, vol. 106, no. 11, pp. 2989–2995.

Fu, H., Chen, C.Y., Li, J.Q., and Zhang, X.Q., Effect of sodium thiosulfate on corrosion behavior of Q235 steel in alkaline solution, Hot Work. Technol., 2017, vol. 46, no. 8, pp. 87–90, 93.

Wu, M.M., Chang, B.W., Lim, T.T., Oh, W.D., Lei, J.X., and Mi, J., High-sulfur capacity and regenerable Zn-based sorbents derived from layered double hydroxide for hot coal gas desulfurization, J. Hazard. Mater., 2018, vol. 360, pp. 391–401.

ACKNOWLEDGMENTS

We gratefully acknowledge the support received from the National Natural Science Foundation of China (nos. 22068021 and 52064030) and the Project of State Key Research and Development Plan (2019YFC1904205).

Author information

Authors and Affiliations

Corresponding authors

Ethics declarations

The authors declare that they have no conflicts of interest.

About this article

Cite this article

Zhanwei Liu, Yan, H., Li, M. et al. Sulfur Removal from High-Sulfur Bauxite during the Bayer Process. Russ. J. Non-ferrous Metals 63, 26–36 (2022). https://doi.org/10.3103/S1067821222010126

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.3103/S1067821222010126