Abstract

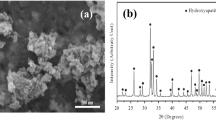

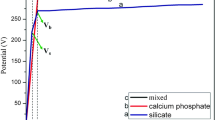

This study covers the influence of bipolar pulsed regime parameters of titanium plasma electrolytic oxidation (PEO): voltage (U), pulse duration (t), and pause duration between pulses on the structure and morphology of TiO2 coatings doped with Ca and P. Threshold values of voltage (U1) and positive pulse duration (t1), which led to pore-free coating formation, are determined. It is shown that an increase in U1 leads to an increase in pore size and Ca and P concentration in the TiO2 coating. A relationship between rutile content in the coating and Ca and P concentrations is identified. It is found that the size and distribution of pores depend on t1. A structure with fine pores evenly distributed over the sample area is formed during a short positive pulse. An increase in t1 leads to the formation of a structure with unevenly distributed large pores. An increase in the values of U2 and t2 leads to a decrease in Ca and P concentrations and rutile content in the coating. It is shown that the surface of PEO TiO2 coatings ensures the growth of crystallites of (Ca, P)-containing phases when kept in a simulated body fluid (SBF) solution. It is found that the amount of apatite-like layer depends on the content of Ca and P in the TiO2 layer, as well as the size and distribution of pores.

Similar content being viewed by others

REFERENCES

Ratner, B.D., Hoffman, A.S., Schoen, A.S., and Lemons, J.E., Biomaterials Science: An Introduction to Materials in Medicine, Oxford: Elsevier, 2004.

Brånemark, P.-I., Zarb, G., and Albrektsso, T., Introduction to osseointegration, in Tissue-Integrated Prostheses: Osseointegration in Clinical Dentistry, Chicago: Quintessence Publ., 1985.

Albrektsson, T., Brånemark, P.I., Hansson, H.A., and Lindström, J., Osseointegrated titanium implants: Requirements for ensuring a long-lasting, direct bone-to-implant anchorage in man, Acta Orthop., 1981, vol. 52, no. 2, pp. 155–170. https://doi.org/10.3109/17453678108991776

Tengvall, P. and Lundström, I., Physico-chemical considerations of titanium as a biomaterial, Clin. Mater., 1992, vol. 9, no. 2, pp. 115–134. https://doi.org/10.1016/0267-6605(92)90056-Y

Hallam, P., Haddad, F., and Cobb, J., Pain in the well-fixed, aseptic titanium hip replacement. The role of corrosion, J. Bone Jt. Surg., Br. Vol., 2004, vol. 86, no. 1, pp. 27–30. https://doi.org/10.1302/0301-620X.86B1.14326

Urban, R.M., Jacobs, J.J., Gilbert, J.L., and Galante, J.O., Migration of corrosion products from modular hip prostheses. Particle microanalysis and histopathological findings, J. Bone Jt. Surg., Am. Vol., 1994, vol. 76, no. 9, pp. 1345–1359. https://doi.org/10.2106/00004623-199409000-00009

Manam, N.S., Harun, W.S.W., Shri, D.N.A., Ghani, S.A.C., Kurniawan, T., Ismail, M.H., and Ibrahim, M.H.I., Study of corrosion in biocompatible metals for implants: A review, J. Alloys Compd., 2017, vol. 701, pp. 698–715. https://doi.org/10.1016/j.jallcom.2017.01.196

Siddiqi, A., Payne, A.G.T., De Silva, R.K., and Duncan, W.J., Titanium allergy: Could it affect dental implant integration?, Clin Oral Implants Res., 2011, vol. 22, no. 7, pp. 673–680. https://doi.org/10.1111/j.1600-0501.2010.02081.x

Egusa, H., Ko, N., Shimazu, T., and Yatani, H., Suspected association of an allergic reaction with titanium dental implants: A clinical report, J. Prosthet. Dent., 2008, vol. 100, no. 5, pp. 344–347. https://doi.org/10.1016/S0022-3913(08)60233-4

Sollazzo, V., Vincenzo, M.D., Pezzetti, F., Scarano, A., Piattelli, A., Massari, L., Brunelli, G., and Carinci, F., Anatase coating improves implant osseointegration in vivo, J. Craniofacial Surg., 2007, vol. 18, no. 4, pp. 806–810. https://doi.org/10.1097/scs.0b013e3180a7728f

Yerokhin, A.L., Nie, X., Leyland, A., Matthews, A., and Dowey, S.J., Plasma electrolysis for surface engineering, Surf. Coat. Technol., 1999, vol. 122, nos. 2–3, pp. 73–93. https://doi.org/10.1016/S0257-8972(99)00441-7

Rakoch, A.G. and Bardin, I.V., Microarc oxidation of light alloys, Metallurgist, 2010, no. 6., pp. 58–61.

Dong, Q., Chen, C., Wang, D., and Ji, Q., Research status about surface modification of biomedical Ti and its alloys by micro-arc oxidation, Surf. Rev. Lett., 2006, vol. 13, no. 1, pp. 35–43. https://doi.org/10.1142/S0218625X06007792

Mortazavi, G., Jiang, J., and Meletis, E.I., Investigation of the plasma electrolytic oxidation mechanism of titanium, Appl. Surf. Sci., 2019, vol. 488, pp. 370–382. https://doi.org/10.1016/j.apsusc.2019.05.250

Quintero, D., Galvis, O., Calderón, J.A., Castaño, J.G., and Echeverría, F., Effect of electrochemical parameters on the formation of anodic films on commercially pure titanium by plasma electrolytic oxidation, Surf. Coat. Technol., 2014, vol. 258, pp. 1223–1231. https://doi.org/10.1016/j.surfcoat.2014.06.058

Cimenoglu, H., Gunyuz, M., Kose, G.T., Baydogan, M., Uùurlu, F., and Sener, C., Micro-arc oxidation of Ti6Al4V and Ti6Al7Nb alloys for biomedical applications, Mater. Charact., 2011, vol. 62, no. 3, pp. 304–311. https://doi.org/10.1016/j.matchar.2011.01.002

Reshadi, F., Faraji, G., Baniassadi, M., and Tajeddini, M., Surface modification of severe plastically deformed ultrafine grained pure titanium by plasma electrolytic oxidation, Surf. Coat. Technol., 2017, vol. 316, pp. 113–121. https://doi.org/10.1016/j.surfcoat.2017.03.016

Wang, Q., Hu, H., Qiao, Y., Zhang, Z., and Sun, J., Enhanced performance of osteoblasts by silicon incorporated porous TiO2 coating, J. Mater. Sci. Technol., 2012, vol. 28, no. 2, pp. 109–117. https://doi.org/10.1016/S1005-0302(12)60030-9

Li, Y., Wang, W., Li, H., Lei, J., and Qi, M., Formation and in vitro/in vivo performance of “cortex-like” micro/nano-structured TiO2 coatings on titanium by micro-arc oxidation, Mater. Sci. Eng., C., 2018, vol. 87, pp. 90–103. https://doi.org/10.1016/j.msec.2018.02.023

Della Valle, C., Rondelli, G., Cigada, A., Bianchi, A.E., and Chiesa, R., A novel silicon-based electrochemical treatment to improve osteointegration of titanium implants, J. Appl. Biomater. Funct. Mater., 2012, vol. 11, no. 2, pp. 106–116. https://doi.org/10.5301/JABFM.2012.9419

Santos-Coquillat, A., Gonzalez Tenorio, R., Mohedano, M., Martinez-Campos, E., Arrabal, R., and Matykina, E., Tailoring of antibacterial and osteogenic properties of Ti6Al4V by plasma electrolytic oxidation, Appl. Surf. Sci., 2018, vol. 454, pp. 157–172. https://doi.org/10.1016/j.apsusc.2018.04.267

Santos-Coquillat, A., Mohedano, M., Martinez-Campos, E., Arrabal, R., Pardo, A., and Matykina, E., Bioactive multi-elemental PEO-coatings on titanium for dental implant applications, Mater. Sci. Eng., C., 2019, vol. 97, pp. 738–752. https://doi.org/10.1016/j.msec.2018.12.097

Gittens, R.A., McLachlan, T., Olivares-Navarrete, R., Cai, Y., Berner, S., Tannenbaum, R., Schwartz, Z., Sandhage, K.H., and Boyan, B.D., The effects of combined micron-/submicron-scale surface roughness and nanoscale features on cell proliferation and differentiation, Biomaterials, 2011, vol. 32, no. 13, pp. 3395–3403. https://doi.org/10.1016/j.biomaterials.2011.01.029

Santos-Coquillat, A., Martínez-Campos, E., Mohedano, M., Martínez-Corriá, R., Ramos, V., Arrabal, R., Matykina, E., In vitro and in vivo evaluation of PEO-modified titanium for bone implant applications, Surf. Coat. Technol., 2018, vol. 347, pp. 358–368. https://doi.org/10.1016/j.surfcoat.2018.04.051

Riehle, M.O., Dalby, M.J., Johnstone, H., MacIntosh, A., and Affrossman, S., Cell behaviour of rat calvaria bone cells on surfaces with random nanometric features, Mater. Sci. Eng., C., 2003, vol. 23, no. 3, pp. 337–340. https://doi.org/10.1016/S0928-4931(02)00282-5

Buser, D., Schenk, R.K., Steinemann, S., Fiorellini, J.P., Fox, C.H., and Stich, H., Influence of surface characteristics on bone integration of titanium implants. A histomorphometric study in miniature pigs, J. Biomed. Mater. Res., 1991, vol. 25, no. 7, pp. 889–902. https://doi.org/10.1002/jbm.820250708

Raines, A.L., Olivares-Navarrete, R., Wieland, M., Cochran, D.L., Schwartz, Z., and Boyan, B.D., Regulation of angiogenesis during osseointegration by titanium surface microstructure and energy, Biomaterials, 2010, vol. 31, no. 18, pp. 4909–4917. https://doi.org/10.1016/j.biomaterials.2010.02.071

Tian, Y., Ding, S., Peng, H., Lu, S., Wang, G., Xia, L., and Wang, P., Osteoblast growth behavior on porous-structure titanium surface, Appl. Surf. Sci., 2012, vol. 261, pp. 25–30. https://doi.org/10.1016/j.apsusc.2012.07.035

Greiner, A.M., Sales, A., Chen, H., Biela, S.A., Kaufmann, D., and Kemkemer, R., Nano- and microstructured materials for in vitro studies of the physiology of vascular cells, Beilstein J. Nanotechnol., 2016, vol. 7, no. 1, pp. 1620–1641. https://doi.org/10.3762/bjnano.7.155

Rupp, F., Scheideier, L., Olshanska, N., De Wild, M., Wieland, M., and Geis-Gerstorfer, J., Enhancing surface free energy and hydrophilicity through chemical modification of microstructured titanium implant surfaces, J. Biomed. Mater. Res., Part A, 2002, vol. 76, no. 2, pp. 323–334. https://doi.org/10.1002/jbm.a.30518

Rao, X., Chu, C.L., Sun, Q., and Zheng, Y.Y., Fabrication and apatite inducing ability of different porous titania structures by PEO treatment, Mater. Sci. Eng., C, 2016, vol. 66, pp. 297–305. https://doi.org/10.1016/j.msec.2016.04.038

Sul, Y.T., Johansson, C.B., Jeong, Y., Wennerberg, A., and Albrektsson, T., Resonance frequency and removal torque analysis of implants with turned and anodized surface oxides, Clin. Oral Implants Res., 2002, vol. 13, no. 3, pp. 252–259. https://doi.org/10.1034/j.1600-0501.2002.130304.x

KrzaĈkaãa, A., Kazek-Kčsik, A., and Simka, W., Application of plasma electrolytic oxidation to bioactive surface formation on titanium and its alloys, RSC Adv., 2013, vol. 3, no. 43, pp. 19725–19743. https://doi.org/10.1039/c3ra43465f

Torres-Ceron, D.A., Restrepo-Parra, E., Acosta-Medina, C.D., Escobar-Rincon, D., and Ospina-Ospina, R., Study of duty cycle influence on the band gap energy of TiO2/P coatings obtained by PEO process, Surf. Coat. Technol., 2019, vol. 375, pp. 221–228. https://doi.org/10.1016/j.surfcoat.2019.06.021

Montazeri, M., Dehghanian, C., Shokouhfar, M., and Baradaran, A., Investigation of the voltage and time effects on the formation of hydroxyapatite-containing titania prepared by plasma electrolytic oxidation on Ti–6Al–4V alloy and its corrosion behavior, Appl. Surf. Sci., 2011, vol. 257, no. 16, pp. 7268–7275. https://doi.org/10.1016/j.apsusc.2011.03.103

Du, Q., Wei, D., Wang, Y., Cheng, S., Liu, S., Zhou, Y., and Jia, D., The effect of applied voltages on the structure, apatite-inducing ability and antibacterial ability of micro arc oxidation coating formed on titanium surface, Bioact. Mater., 2018, vol. 3, no. 4, pp. 426–433. https://doi.org/10.1016/j.bioactmat.2018.06.001

Sedelnikova, M.B., Komarova, E. G., Sharkeev, Y.P., Ugodchikova, A.V., Tolkacheva, T.V., Rau, J.V., Buyko, E.E., Ivanov, V.V., and Sheikin, V.V., Modification of titanium surface via Ag-, Sr- and Si-containing micro-arc calcium phosphate coating, Bioact. Mater., 2019, vol. 4, pp. 224–235. https://doi.org/10.1016/j.bioactmat.2019.07.001

Wang, Y., Jiang, B., Lei, T., and Guo, L., Dependence of growth features of microarc oxidation coatings of titanium alloy on control modes of alternate pulse, Mater. Lett., 2004, vol. 58, nos. 12–13, pp. 1907–1911. https://doi.org/10.1016/j.matlet.2003.11.026

Zhang, X., Yang, L., Lu, X., Lv, Y., Jiang, D., Yu, Y., Peng, Z., and Dong, Z., Characterization and property of dual-functional Zn-incorporated TiO2 micro-arc oxidation coatings: The influence of current density, J. Alloys Compd., 2019, vol. 810, p. 151893. https://doi.org/10.1016/j.jallcom.2019.151893

Kuchmin, I.B. and Nechaev, G.G., Current density as defining parameter of microarc oxidation process, Vestn. Sarat. Gos. Tekh. Univ., 2013, no. 1, pp. 62–65.

Ntomprougkidis, V., Martin, J., Nominé, A., and Henrion, G., Sequential run of the PEO process with various pulsed bipolar current waveforms, Surf. Coat. Technol., 2019, vol. 374, pp. 713–724. https://doi.org/10.1016/j.surfcoat.2019.06.057

Gnedenkov, S.V., Sharkeev, Yu.P., Sinebryukhov, S.L., Khrisanfova, O.A., Legostaeva, E.V., Zavidnaya, A.G., Puz’, A.V., and Khlusov, I.A., Formation and properties of bioactive coatings titanium, Perspekt. Mater., 2011, no. 2, pp. 33–37.

Rakoch, A.G., Bautin, V.A., Bardin, I.V., and Kovalev, V.L., The mechanism and kinetic features of microarc oxidation of ML5PCh magnesium alloy in electrolytes containing NH4F, Korroz.: Mater., Zashch., 2007, no. 9, pp. 7–13.

Sinebryukhov, S.L., Composite multifunctional coatings formed on metals and alloys by plasma electrolytic oxidation, Extended Abstract of Cand. Sci. (Eng.) Dissertation, Vladivostok: Institute of Chemistry, Far-Eastern Branch Russ. Acad. Sci., 2013.

Marques, M., Laobenberg, R., and Almukainzi, M., Simulated biological fluids with possible application in dissolution testing, Dissolution Technol., 2011, vol. 18, pp. 15–28.

Ponomarev, V.A., Orlov, E.A., Malikov, N.A., Tarasov, Y.V., Sheveyko, A.N., Permyakova, E.S., Kuptsov, K.A., Dyatlov, I.A., Ignatov, S.G., Ilnit-skaya, A.S., Gloushankova, N.A., Subramanian, B., and Shtansky, D.V., Ag(Pt) nanoparticles-decorated bioactive yet antibacterial Ca- and P-doped TiO2 coatings produced by plasma electrolytic oxidation and ion implantation, Appl. Surf. Sci., 2020, vol. 516, p. 146068.

Rakoch, A.G., Bardin, I.V., Kovalev, V.L., and Avanesyan, T.G., Microarc oxidation of light structural alloys. Part 1. The basic representation of microarc oxidation of light structural alloys, Izv. Vyssh. Uchebn. Zaved., Poroshk. Metall. Funkts. Pokrytiya, 2011, no. 2, pp. 58–62.

Gordienko, P.S. and Gnedenkov, S.V., Mikrodugovoe oksidirovanie titana i ego splavov (Microarc Oxidation of Titanium and its Alloys), Vladivostok: Dal’nauka, 1997.

Kolobov, Yu.R., Druchinina, O.A., Ivanov, M.B., Sirota, V.V., Lazebnaya, M.A., Khramov, G.V., Trusova, Ya.V., Sergeeva, N.S., and Sviridova, I.K., Formation of porous composite bioactive coatings on titanium alloys VT6 and VT16 via microarc oxidation treatment, Nano-Mikrosist. Tekh., 2009, no. 2 (103), pp. 48–54.

Sedel’nikova, M.B., Sharkeev, Yu.P., Komarova, E.G., and Tolkacheva, T.V., Influence of microarc oxidation process parameters on formation and properties of bio-coatings based on wollastonite and calcium phosphates, Fiz. Khim. Obrab. Mater., 2016, no. 6, pp. 57–63.

ACKNOWLEDGMENTS

This study was funded by the Russian Foundation for Basic Research as part of Scientific Project no. 19-38-90249\19.

Author information

Authors and Affiliations

Corresponding authors

Additional information

Translated by A. Muravev

About this article

Cite this article

Ponomarev, V.A., Kuptsov, K.A., Sheveyko, A.N. et al. Dependence of Morphology, Structure, Composition and Biocompatibility of Ca- and P-Doped TiO2 Coatings on PEO Process Parameters. Russ. J. Non-ferrous Metals 62, 618–628 (2021). https://doi.org/10.3103/S1067821221050187

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.3103/S1067821221050187