Abstract

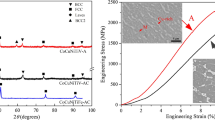

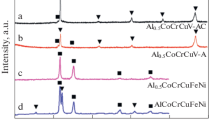

A novel 3d transition metal high entropy alloy (3d TM HEA), CoCrCuNiTi, was exploited by Ti addition into a common 4-elemental group of CoCrCuNi. Its phase constitution, microstructure, and compressive properties in as-cast and annealed conditions were investigated. The studied alloys in both states were composed of a complex multiphase structure, including two BCC phases, one FCC phase, one cubic laves phase, and one HCP Ni3Ti phase. The two BCC phases took up around 50 vol % in total, and the other three phases occurred within the remaining regions. The majority of the BCC phases were attributed to the promising ultimate compressive strength of the studied alloys in both conditions (as-cast: 2.53 GPa, annealed: 2.22 GPa). Furthermore, an outstanding hardness of 694 HV was obtained in the as-cast alloy, implying that no strong relationship was exhibited among the hardness, phase constituent, or valence electron concentration (VEC) in the CoCrCuNi-base HEAs system.

Similar content being viewed by others

REFERENCES

Yeh, J.W., Chen, S.K., and Lin, S.J., et al., Nanostructured high-entropy alloys with multiple principal elements: novel alloy design concepts and outcomes, Adv. Eng. Mater., 2004, vol. 6, pp. 299–303.

Cantor, B., Chang, I.T.H., Knight, P., et al., Microstructural development in equiatomic multicomponent alloys, Mater. Sci. Eng., A, 2004, vols. 375–377, pp. 213–218.

Miracle, D.B. and Senkov, O.N., A critical review of high entropy alloys and related concepts, Acta Mater., 2017, vol. 122, pp. 448–511.

Tsai, M.H. and Yeh, J.W., High-entropy alloys: a critical review, Mater. Res. Lett., 2014, vol. 2, no. 3, pp. 107–123.

Zhang, Y., Zuo, T.T., Tang, Z., et al., Microstructures and properties of high-entropy alloys, Prog. Mater. Sci., 2014, vol. 61, pp. 1–93.

Yeh, J.W., Chen, S.K., Gan, J.Y., et al., Formation of simple crystal structures in Cu–CoNi–Cr–Al–Fe–Ti–V alloys with multiprincipal metallic elements, Metall. Mater. Trans. A, 2004, vol. 35, pp. 2533–2536.

Tong, C.J., Chen, M.R., Chen, S.K., et al., Mechanical performance of the AlxCoCrCuFeNi high-entropy alloy system with multiprincipal elements, Metall. Mater. Trans. A, 2004, vol. 36, pp. 1263–1271.

Eleti, R.R., Bhattacharjee, T., Shibata, A., et al., Unique deformation behavior and microstructure evolution in high temperature processing of HfNbTaTiZr refractory high entropy alloy, Acta Mater., 2019, vol. 171, pp. 132–145.

Li, J., Fang, Q., Liu, B., et al., Transformation induced softening and plasticity in high entropy alloys, Acta Mater., 2018, vol. 147, pp. 35–41.

Basu, I., Ocelik, V., and De Hosson, J.T.M., Size dependent plasticity and damage response in multiphase body centered cubic high entropy alloys, Acta Mater., 2018, vol. 150, pp. 104–116.

Quiambao, K.F., McDonnell, S.J., Schreiber, D.K., et al., Passivation of a corrosion resistant high entropy alloy in non-oxidizing sulfate solutions, Acta Mater., 2019, vol. 164, pp. 362–376.

Hsu, Y.J., Chiang, W.C., and Wu, J.K., Corrosion behavior of FeCoNiCrCux high-entropy alloys in 3.5% sodium chloride solution, Mater. Chem. Phys., 2005, vol. 92, no. 1, pp. 112–117.

Zhou, Y.J., Zhang, Y., Wang, Y.L., et al., Microstructure and compressive properties of multicomponent Alx(TiVCrMnFeCoNiCu)100−x high-entropy alloys, Mater. Sci. Eng., A, 2007, vols. 454–455, pp. 260–265.

Derimow, N., Clark, T., Roach, C., et al., Processing pathway effects in CoCrCuNi + X (Fe, Mn) high-entropy alloys, Philos. Mag., 2019, vol. 99, no. 15, pp. 1899–1913.

Hsu, U.S., Hung, U.D., Yeh, J.W., et al., Alloying behavior of iron, gold and silver in AlCoCrCuNi-based equimolar high-entropy alloys, Mater. Sci. Eng., A, 2007, vols. 460–461, pp. 403–408.

Tsai, M.H., Yuan, H., Cheng, G., et al., Morphology, structure and composition of precipitates in Al0.3CoCrCu0.5FeNi high-entropy alloy, Intermetallics, 2013, vol. 32, pp. 329–336.

Jung, J., Lee, S.J., Kim, S., et al., Effect of Ti additions on micro-alloyed Nb TRIP steel, Steel Res. Int., 2011, vol. 82, no. 7, pp. 857–865.

He, T.T., Wang, W., Chen, D.M., et al., Effect of Ti on the microstructure and Al-water reactivity of Al-rich alloy, Int. J. Hydrogen Energy, 2014, vol. 39, no. 2, pp. 684–691.

Zhou, Y.J., Zhang, Y., Wang, Y.L., et al., Solid solution alloys of AlCoCrFeNiTix with excellent room-temperature mechanical properties, Appl. Phys. Lett., 2007, vol. 90, no. 18, p. 181904.

Chen, M.R., Lin, S.J., Yeh, J.W., et al., Microstructure and properties of Al0.5CoCrCuFeNiTix (x = 0–2.0) high-entropy alloys, Mater. Trans., 2006, vol. 47, no. 5, pp. 1395–1401.

Hu, Z., Zhan, Y., Zhang, G., et al., Effect of rare earth Y addition on the microstructure and mechanical properties of high entropy AlCoCrCuNiTi alloys, Mater. Des., 2010, vol. 31, no. 3, pp. 1599–1602.

Varalakshmi, S., Kamaraj, M., and Murty, B.S., Processing and properties of nanocrystalline CuNiCoZnAlTi high entropy alloys by mechanical alloying, Mater. Sci. Eng., A, 2010, vol. 527, nos. 4–5, pp. 1027–1030.

Wang, X.F., Zhang, Y., Qiao, Y., et al., Novel microstructure and properties of multicomponent CoCrCuFeNiTix alloys, Intermetallics, 2007, vol. 15, no. 3, pp. 357–362.

Cai, Z., Jin, G., Cui, X., et al., Experimental and simulated data about microstructure and phase composition of a NiCrCoTiV high-entropy alloy prepared by vacuum hot-pressing sintering, Vacuum, 2016, vol. 124, pp. 5–10.

Couzinié, J.P., Lilensten, L., Champion, Y., et al., On the room temperature deformation mechanisms of a TiZrHfNbTa refractory high-entropy alloy, Mater. Sci. Eng., A, 2015, vol. 645, pp. 255–263.

Senkov, O.N., Scott, J.M., Senkova, S.V., et al., Microstructure and room temperature properties of a high-entropy TaNbHfZrTi alloy, J. Alloys Compd., 2011, vol. 509, no. 20, pp. 6043–6048.

Wang, W.R., Wang, W.L., Wang, S.C., et al., Effects of Al addition on the microstructure and mechanical property of AlxCoCrFeNi high-entropy alloys, Intermetallics, 2012, vol. 26, pp. 44–51.

Kao, Y.F., Chen, T.J., Chen, S.K., et al., Microstructure and mechanical property of as-cast, -homogenized, and -deformed AlxCoCrFeNi (0 ≤ x ≤ 2) high-entropy alloys, J. Alloys Compd., 2009, vol. 488, no. 1, pp. 57–64.

Tsai, M.H., Tsai, K.Y., Tsai, C.W., et al., Criterion for sigma phase formation in Cr- and V-containing high-entropy alloys, Mater. Res. Lett., 2013, vol. 1, no. 4, pp. 207–212.

Tung, C.C., Yeh, J.W., Shun, T., et al., On the elemental effect of AlCoCrCuFeNi high-entropy alloy system, Mater. Lett., 2007, vol. 61, no. 1, pp. 1–5.

Li, A., Ma, D., and Zheng, Q., Effect of Cr on microstructure and properties of a series of AlTiCrxFeCoNiCu high-entropy alloys, J. Mater. Eng. Perform., 2014, vol. 23, no. 4, pp. 1197–1203.

ACKNOWLEDGMENTS

Financial supports from the Natural Science Foundation of China (Grants no. 51801124) and Natural Science Research of Jiangsu Higher Education Institutions of China (Grants no. 18KJB430012) are gratefully acknowledge.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

We declared that the present work has no conflicts with other researchers or organizations.

About this article

Cite this article

Yi, J., Yang, L., Xu, M. et al. Investigation of a Novel CoCrCuNiTi High Entropy Alloy on Microstructure and Mechanical Properties. Russ. J. Non-ferrous Metals 62, 197–205 (2021). https://doi.org/10.3103/S1067821221020073

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.3103/S1067821221020073