Abstract

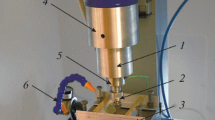

Single- and double-layer coatings on 40Cr steel substrates have been obtained by electrospark alloying (ESA) and a combination of ESA technology and pulsed cathodic arc evaporation (PCAE) using TiCNiCr and TiCNiCr–Dy2O3 electrodes. The electrodes are obtained by powder metallurgy. The structure and elemental and phase composition of the electrodes and coatings are studied using scanning electron microscopy, energy dispersive spectroscopy, and X-ray phase analysis. The tribological properties of the coatings are determined as a result of tests according to the pin-on-disk scheme in contact with the Al2O3 counterbody at loads of 1, 5, and 10 N. The temperature during the tests is T = 20°C. The potential and current density of corrosion are determined using a three-electrode cell with a VoltaLab 50 potentiostat. The results show that the electrodes consist of TiC grains of 12 μm; a solid solution of Ni in Cr; and, in the case of a doped electrode, Dy2O3 up to 5 μm in size. ESA coatings have a low-defect fine-grained structure consisting of regions of a solid solution of Ni and Cr in Fe and titanium carbide grains with a maximum size of 0.3 μm. Coatings with the addition of Dy2O3 have a lower coefficient of friction at loads of 1, 5, and 10 N. All coatings in 1 N H2SO4 are in a stable passive state and have high corrosion resistance: the corrosion current density of the coatings is at least 4 times lower than the values obtained for a 40Cr steel substrate.

Similar content being viewed by others

REFERENCES

Wang, X., He, X., and Guo, H., Influence of Mo on the microstructure and mechanical properties of TiC-based cermets, Rare Met., 2010, vol. 29, pp. 346–350.

Levinskii, Yu.V. and Petrov, A.P., Tungsten-free hard alloys based on titanium carbide, Inorg. Mater., 2000, vol. 36, pp. 24–27.

Rajabi, A., Ghazali, M.J., Syarif, J., and Daud, A.R., Development and application of tool wear: A review of the characterization of TiC-based cermets with different binders, Chem. Eng. J., 2014, vol. 255, pp. 445–452.

Liu, Z., Tian, J., Li, B., and Zhao, L., Microstructure and mechanical behaviors of in situ TiC particulates reinforced Ni matrix composite, Mater. Sci. Eng., A, 2010, vol. 527, pp. 3898–3903.

Kiryukhantsev-Korneev, Ph.V., Sheveyko, A.N., Shvindina, N.V., Levashov, E.A., and Shtansky, D.V., Comparative study of Ti–C–Ni–Al, Ti–C–Ni–Fe, and Ti–C–Ni–Al/Ti–C–Ni–Fe coatings produced by magnetron sputtering, electro-spark deposition, and a combined two-step process, Ceram. Int., 2018, vol. 44, pp. 7637–7646.

Andreev, A.V., Litovchenko, I.Y., Korotaev, A.D., and Borisov, D.P., Thermal stability of Ti–C–Ni–Cr and Ti–C–Ni–Cr–Al–Si nanocomposite coatings, J. Phys.: Conf. Ser., 2015, vol. 652, p. 012057.

Nikolenko, S.V., Verkhoturov, A.D., Syui, N.A., and Kuz’michev, E.N., Influence of electrospark discharge parameters on roughness and microabrasive wear of steel 45 surface after ESA by TiC-based electrodes, Surf. Eng. Appl. Electrochem., 2016, vol. 52, pp. 342–349.

Levashov, E.A., Malochkin, O.V., Kudryashov, A.E., Gammel, F., and Suchentrunk, R., Effects of nanocrystalline powders additions on the characteristics of combustion process, phase and structure-formation, and properties of SHS alloys on titanium carbide base, J. Mater. Synth. Process., 2002, vol. 10, pp. 231–236.

Quazi, M.M., Fazal, M.A., Hasee, A.S.M.A., Yusof, F., Masjuki, H.H., and Arslan, A., Effect of rare earth elements and their oxides on tribo-mechanical performance of laser claddings: A review, J. Rare Earths, 2016, vol. 34, pp. 549–564.

Zhu, R., Li, Z., Li, X., and Sun, Q., Microstructure and properties of the low-power-laser clad coatings on magnesium alloy with different amount of rare earth addition, Appl. Surf. Sci., 2015, vol. 353, pp. 405–413.

Kiryukhantsev-Korneev, F.V., Sytchenko, A.D., Kudryashov, A.E., and Levashov, E.A., Protective coatings produced by electro-spark deposition with TiCNiCr–(Eu2O3) electrodes, CIS Iron Steel Rev., 2018, vol. 16, pp. 57–62.

Kiryukhantsev-Korneev, Ph., Sytchenko, A., Sheveyko, A., and Vorotilo, S., Deposited by pulsed cathodic arc evaporation in Ar, N2, and C2H4 environments using the TiC–NiCr–Eu2O3 cathode, Coatings, 2019, vol. 9, pp. 230–243.

Kiryukhantsev-Korneev, Ph.V., Sytchenko, A.D., and Levashov, E.A., Comparative study of electrospark alloying coatings formed using TiC–NCr and TiC–NiCr–Eu2O3 electrodes, Russ. J. Non-Ferrous Met., 2019, vol. 60, no. 6, pp. 662–672.

Kiryukhantsev-Korneev, Ph.V., Sheveyko, A.N., Kuptsov, K.A., Novikov, A.V., and Shtansky, D.V., Ti–Cr–B–N coatings prepared by pulsed cathodic-arc evaporation of ceramic TiCrB target produced by SHS, Prot. Met. Phys. Chem. Surf., 2013, vol. 49, pp. 677–681.

Dong, X., Cheng, X.L., Zhang, X.F., Sui, L.L., Xu, Y.M., and Gao, S., A novel coral-shaped Dy2O3 gas sensor for high sensitivity NH3 detection at room temperature, Sens. Actuators, B, 2018, vol. 255, pp. 1308–1315.

Wei, C.C., Transparent ceramics for lighting, J. Eur. Ceram. Soc., 2009, vol. 29, pp. 237–244.

Ramay, S.M. and Saleem, M., Magnetron sputtered Dy2O3 with chromium and copper contents for antireflective thin films with enhanced absorption, J. Rare Earths, 2019, vol. 37, pp. 989–994.

Liu, X. and Huang, W., Preparation and tribological performance of electrodeposited Ni–TiB2–Dy2O3 composite coatings, J. Rare Earths, 2009, vol. 27, pp. 480–485.

ACKNOWLEDGMENTS

We are grateful to N.V. Shvyndina (MISiS) for help in conducting structural studies of coatings.

Funding

This study was supported by the Russian Science Foundation (project no. 15-19-00203-P).

Author information

Authors and Affiliations

Corresponding authors

Ethics declarations

The authors declare that they have no conflict of interest.

About this article

Cite this article

Sytchenko, A.D., Sheveyko, A.N., Levashov, E.A. et al. Tribological Characteristics and Corrosion Resistance of Coatings Obtained by Electrospark Alloying, Pulsed Cathodic Arc Evaporation, and Hybrid Technology Using TiCNiCr and TiCNiCr–Dy2O3 Electrodes. Russ. J. Non-ferrous Metals 61, 325–331 (2020). https://doi.org/10.3103/S1067821220030177

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.3103/S1067821220030177