Abstract

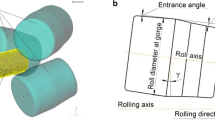

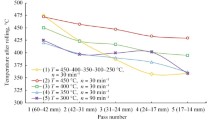

This work is devoted to the finite-element modeling of the deformation mode of a small-diameter rod billet during pressure hot treatment in the combination of radial shear rolling (RSR) and rotary forging (RF). Modeling is performed using a rheological model of the Ti–6Al–4V titanium alloy using the QForm VX program. The combination of RSR for one passage of a billet 15 mm in diameter to a rod 12 mm in diameter and subsequent RF in 1, 2, and 3 passages with the formation of rods 11, 10, and 8 mm in diameter is modeled. The operation-by-operation accumulation of the plastic deformation in nonuniformity conditions of its distribution is taken into account. Intermediate and final plastic deformation fields, deformation rates, and average stresses are found. It is shown that the distribution of the plastic deformation after RSR has the pronounced gradient character with a minimal value (3 and larger) at the cross-section periphery and a minimal value (about 1) in the center. Due to this, RF, even with small reductions, leads to a substantial increase in uniformity of the deformation mode when compared with the billet after the same diameter after radial shear rolling only. In addition, residual tensile stresses decrease due to compressing stresses during RF. The direct experimental approval of the combined deformation method is performed for the promising Ti–Zr–Nb shape memory alloy of medical prescription when fabricating rods 7–8 mm in diameter under pilot production conditions. The results of modeling are qualitatively confirmed by the metallographic analysis. The prospects of a combination of RSR and RF for the development of industrial fabrication technologies of small-diameter rods with a high uniformity of finely dispersed structure are shown.

Similar content being viewed by others

REFERENCES

Geetha, M., Singh, A.K., Asokamani, R., and Gogia, A.K., Ti based biomaterials, the ultimate choice for orthopaedic implants - A review, Prog. Mater. Sci., 2009, vol. 54, no. 3, pp. 397–425.

Kim, H.Y., Fu, J., Tobe, H., Kim, J.I., and Miyazaki, S., Crystal structure, transformation strain, and super-elastic property of Ti–Nb–Zr and Ti–Nb–Ta alloys, Shape Mem. Superelasticity, 2015, vol. 1, no. 2, pp. 107–116.

Sheremet’ev, V.A., Kudryashova, A.A., Dinh, X.T., Galkin, S.P., Prokoshkin, S.D., and Brailovskii, V., Advanced technology for preparing bar from medical grade Ti–Zr–Nb superelastic alloy based on combination of radial-shear rolling and rotary forging, Metallurgist, 2019, vol. 63, nos. 1–2, pp. 51–61.

Sheremetyev, V., Kudryashova, A., Cheverikin, V., Korotitskiy, A., Galkin, S., Prokoshkin, S., and Brailovski, V., Hot radial shear rolling and rotary forging of metastable beta Ti–18Zr–14Nb (at %) alloy for bone implants: Microstructure, texture and functional properties, J. Alloys Compd., 2019, vol. 800, pp. 320–326.

Galkin, S.P., Trajectory of deformed metal as basis for controlling the radial-shift and screw rolling, Stal, 2004, no. 7, pp. 63–66.

Dobatkin, S., Galkin, S., Estrin, Y., Serebryany, V., Diez, M., Martynenko, N., Lukyanova, E., and Perezhogin, V., Grain refinement, texture, and mechanical properties of a magnesium alloy after radial-shear rolling, J. Alloys Compd., 2019, vol. 774, pp. 969–979.

Akopyan, T., Aleshchenko, A.S., Belov, N.A., and Galkin, S.P., Effect of radial-shear rolling on the formation of structure and mechanical properties of Al‒Ni and Al–Ca aluminum-matrix composite alloys of eutectic type, Phys. Met. Metallogr., 2018, vol. 119, no. 3, pp. 241–250.

Karpov, B.V., Patrin, P.V., Galkin, S.P., Kharitonov, E.A., and Karpov, I.B., Radial-shear rolling of titanium alloy VT-8 bars with controlled structure for small diameter ingots (≤200 mm), Metallurgist, 2018, vol. 61, nos. 9–10, pp. 884–890.

Sheremetyev, V., Kudryashova, A., Dubinskiy, S., Galkin, S., Prokoshkin, S., and Brailovski, V., Structure and functional properties of metastable beta Ti–18Zr–14Nb (at %) alloy for biomedical applications subjected to radial shear rolling and thermomechanical treatment, J. Alloys Compd., 2018, vol. 737, pp. 678–683.

Liu, Y., Herrmann, M., Schenck, C., and Kuhfuss, B., Plastic deformation components in mandrel free infeed rotary swaging of tubes, Procedia Manuf., 2019, vol. 27, pp. 33–38.

Al-Khazraji, H., El-Danaf, E., Wollmann, M., and Wagner, L., Microstructure, mechanical, and fatigue strength of Ti–54M processed by rotary swaging, J. Mater. Eng. Perform., 2015, vol. 24, no. 5, pp. 2074–2084.

Moumi, E., Ishkina, S., Kuhfuss, B., Hochrainer, T., Struss, A., and Hunkel, M., 2D-simulation of material flow during infeed rotary swaging using finite element method, Procedia Eng., 2014, vol. 81, pp. 2342–2347.

Vollertsen, F., Micro Metal Forming, Berlin, Heidelberg: Springer, 2013.

Lopatin, N.V., Effect of hot rolling by screw mill on microstructure of a Ti–6Al–4V titanium alloy, Int. J. Mater. Form., 2013, vol. 6, no. 4, pp. 459–465.

Wang, Y.L., Molotnikov, A., Diez, M., Lapovok, R., Kim, H.-E., Wang, J.T., and Estrin, Y., Gradient structure produced by three roll planetary milling: Numerical simulation and microstructural observations, Mater. Sci. Eng., A, 2015, vol. 639, pp. 165–172.

Andreev, V.A., Yusupov, V.S., Perkas, M.M., Prosvirnin, V.V., Shelest, A.E., Prokoshkin, S.D., Khmelevskaya, I.Y., Korotitskii, A.V., Bondareva, S.A., and Karelin, R.D., Mechanical and functional properties of commercial alloy TN-1 semi-products fabricated by warm rotary forging and ECAP, Russ. Metall. (Engl. Transl.), 2017, vol. 2017, vol. 10, pp. 890–894.

Abedian, A., Poursina, M., and Golestanian, H., A Comparison between the properties of solid cylinders and tube products in multi-pass hot radial forging using finite element method, Proc. AIP Conference NUMIFORM’07, Porto, June 17–21, 2007, vol. 908, issue 1, pp. 963–968.

Zhang, Q., Jin, K., Mu, D., Zhang, Y., and Li, Y., Energy-controlled rotary swaging process for tube workpiece, Int. J. Adv. Manuf. Technol., 2015, vol. 80, nos. 9–12, pp. 2015–2026.

Zhang, Q., Jin, K., and Mu, D., Tube/tube joining technology by using rotary swaging forming method, J. Mater. Process. Technol., 2014, vol. 214, no. 10, pp. 2085–2094.

Zhang, Q., Jin, K., Mu, D., Ma, P., and Tian, J., Rotary swaging forming process of tube workpieces, Procedia Eng., 2014, vol. 81, pp. 2336–2341.

Lopatin, N.V. and Galkin, S.P., The effect of combined rolling on the structure and properties of VT1-0 Titanium rods, Izv. Vyssh. Uchebn. Zaved., Tsvetn. Metall., 2013, no. 2, pp. 39–46.

Naizabekov, A., Lezhnev, S., Arbuz, A., and Panin, E., Computer simulation of the combined process “Helical Rolling-Pressing”, Key Eng. Mater., 2016, vol. 716, pp. 614–619.

Pachla, W., Kulczyk, M., Przybysz, S., Skiba, J., Wojciechowski, K., Przybysz, M., Topolski, K., Sobolewski, A., and Charkiewicz, M., Effect of severe plastic deformation realized by hydrostatic extrusion and rotary swaging on the properties of CP Ti grade 2, J. Mater. Process. Technol., 2015, vol. 221, pp. 255–268.

Kolmogorov, V.L., Mekhanika obrabotki metallov davleniem (Metal Forming Mechanics), Moscow: Metallurgiya, 1986.

Wu, Y., Dong, X., and Yu, Q., Upper bound analysis of axial metal flow inhomogeneity in radial forging process, Int. J. Mech. Sci., 2015, vol. 93, pp. 102–110.

Romanenko, V.P., Stepanov, P.P., and Kriskovich, S.M., Production of hollow railroad axles by screw piercing and radial forging, Metallurgist, 2018, vol. 61, nos. 9–10, pp. 873–877.

Funding

This study was supported by the Russian Science Foundation, project no. 18-79-00247.

Author information

Authors and Affiliations

Corresponding authors

Ethics declarations

The authors declare that they have no conflict of interest.

Additional information

Translated by N. Korovin

About this article

Cite this article

Ta Dinh Xuan, Sheremetyev, V.A., Kudryashova, A.A. et al. Influence of the Combined Radial Shear Rolling and Rotary Forging on the Deformation Mode of the Small-Diameter Rod Billet Made of Titanium Alloys. Russ. J. Non-ferrous Metals 61, 271–279 (2020). https://doi.org/10.3103/S1067821220030165

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.3103/S1067821220030165