Abstract

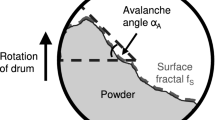

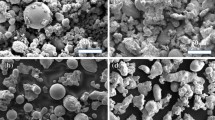

Electron beam melting (EBM) is a powder bed fusion additive manufacturing (AM) technique that produces three-dimensional (3D) parts by fusing metallic powders with a high-energy electron beam. Powder has been major issue for the properties of the final parts. Hence, establishing the effect of powder properties on the final product properties is important for producing parts of quality. In this study, Ta–60Ti, Ta–50Ti, Ta–40Ti was a blend of tantalum and titanium powders. The blend of powder was characterized in terms of the particle size distribution (PSD), bulk and tap density, flowability in Hall Funnel flowmeter and particle morphology. In addition, a universal powder bed (UPB) system was used to characterize the powder behavior raking because the UPB system allows a quick assessment of the powder spreading behavior in AM processes. Surface roughness’s of the powder after raking with universal powder bed (UPB) system, the microstructural heterogeneity, defect distributions were investigated.

Similar content being viewed by others

REFERENCES

ASTM F2792: Standard Terminology for Additive Manufacturing Technologies, West Conshohocken, PA: ASTM Int., 2012.

Levy, G.N., Schindel, R., and Kruth, J.P., Rapid manufacturing and rapid tooling with layer manufacturing (LM) technologies, state of the art and future perspectives, CIRP Ann., 2003, vol. 52, pp. 589–609.

Kruth, J.P., Levy, G., Klocke, F., and Childs, T.H.C., Consolidation phenomena in laser and powder-bed based layered manufacturing, CIRP Ann., 2007, vol. 56, pp. 730–760.

Campbell, J., Bourell, D., and Gibson, J., Additive manufacturing: rapid prototyping comes in age, Rapid Prototyping J., 2012, vol. 18, pp. 255–258.

King, W., Modeling of powder dynamics in metal additive manufacturing, Final Powder Dynamics Meeting Report, 2017.

Herbert, R., Viewpoint: metallurgical aspects of powder bed metal additive manufacturing, J. Mater. Sci., 2016, vol. 51, pp. 1165–1175.

Tan, J., Wong, W., and Dalgarno, K., An overview of powder granulometry on feedstock and part performance in the selective laser melting process, Addit. Manuf., 2017, vol. 18, pp. 228–255.

Drummer, D., Medina- Hernández, M., Drexler, M., and Wudy, K., Polymer powder production for laser melting through immiscible blends, Procedia Eng., 2015, vol. 102, pp. 1918–1925.

Van den Eynde, M., Verbelen, L., and Van Puyvelde, P., Assessing polymer powder flow for the application of laser sintering, Powder Technol., 2015, vol. 286, pp. 151–155.

Zou, R.P. and Yu, A.B., Evaluation of the packing characteristics of mono-sized non-spherical particles, Powder Technol., 1996, vol. 88, pp. 71–79.

Verbelen, L., Dadbakhsh, S., Van den Eynde, M., Kruth, J.P., Goderis, B., and Van Puyvelde, P., Characterization of polyamide powders for determination of laser sintering processability, Eur. Polym. J., 2016, vol. 75, pp. 163–174.

Berretta, S., Ghita, O., and Evans, K.E., Morphology of polymeric powders in Laser Sintering (LS): from polyamide to new PEEK powders, Eur. Polym. J., 2014, vol. 59, pp. 218–229.

Whiting, J. and Fox, J., Characterization of feedstock in the powder bed fusion process: sources of variation in particle size distribution and the factors that influence them, Proc. Int. Solid Freeform Fabrication Symposium, Austin, TX: 2016.

Mindt, H., Megahed, M., Lavery, N., Holmes, M., and Brown, S., Powder bed layer characteristics: the overseen first-order process input, Metall. Mater. Trans. A, 2016, vol. 47, pp. 3811–3822.

Haeri, S., Optimization of blade type spreaders for powder bed preparation in additive manufacturing using DEM simulations, Powder Technol., 2017, vol. 321, pp. 94–104.

Walton, O., Review of adhesion fundamentals for micron scale particles, KONA Powder Part. J., 2008, vol. 26, pp. 129–141.

Herbold, E., Walton, O., and Homel, M., Simulation of Powder Layer Deposition in Additive Manufacturing Processes Using the Discrete Element Method. Technical Report, Livermore, CA: Lawrence Livermore National Lab., 2015.

Foster, B.K., Reutzel, E.W., Nassar, A.R., Hall, B.T., Brown, S.W. and Dickman, C.J., Optical, layerwise monitoring of powder bed fusion, Proc. 26th Annual Int. Solid Freeform (SFF) Symposium, Austin, TX: Univ. of Texas, 2015, pp. 295–307.

Helsen, J.A. and Missirlis, Y., Biomaterials—a Tantalus Experience, Berlin, Heidelberg: Springer, 2010.

Zhou, Y.L. and Niinomi, M., Ti–25Ta alloy with the best mechanical compatibility in Ti–Ta alloys or bio- medical applications, Mater. Sci. Eng., C, 2009, vol. 29, pp. 1061–1065.

Jaffee, R.I., The physical metallurgy of titanium alloys, J. Met., 1955, vol. 7, p. 247.

Fuerst, J., Medlin, D., Carter, M., Sears, J., and Voort, G.V., LASER additive manufacturing of titanium–tantalum alloy structured interfaces for modular orthopedic devices, JOM, 2015, vol. 67, no. 4, pp. 775–780.

Black, J., Biologic performance of tantalum, Clin. Mater., 1994, vol. 16, pp. 167–173.

Harling, R.J., Biocompatibility of Tantalum and Tantalum Coated Material. Technical Report, Danfoss Tantalum Technologies, 2002.

Crochet, D., Grossetête, R., Bach-Lijour, B., Sagan, C., Lecomte, E., Leurent, B., Brunel, P., and Le Nihouannen, J.C., Plasma treatment effects on the tantalum Strecker stent implanted in femoral arteries of sheep, Cardiovasc. Interventions Radiol., 1994, vol. 17, pp. 285–291.

Bobyn, J.D., Stackpool, G.J., Hacking, S.A., Tanzer, M., and Krygier, J.J., Characteristics of bone ingrowth and interface mechanics of a new porous tantalum biomaterial, J. Bone Jt. Surg., 1999, vol. 81, pp. 907–914.

Levine, B.R., Sporer, S., Poggie, R.A., Della Valle, C.J., and Jacobs, J.J., Experimental and clinical performance of porous tantalum in orthopedic surgery, Biomaterials, 2006, vol. 27, pp. 4671–4681.

Yap, C.Y., Chua, C.K., Dong, Z.L., Liu, Z.H., Zhang, D.Q., Loh, L.E., and Sing, S.L., Review of selective laser melting: materials and applications, Appl. Phys. Rev., 2015, vol. 2, p. 041101.

Sing, S.L., An, J., Yeong, W.Y., and Wiria, F.E., Laser and electron-beam powder-bed additive manufacturing of metallic implants: a review on processes, materials and designs, J. Orthop. Res., 2016, vol. 34, pp. 369–385.

Zhang, L.-C. and Attar, H., Selective laser melting of titanium alloys and titanium matrix composites for biomedical applications: a review, Adv. Eng. Mater., 2016, vol. 18, pp. 463–475.

Sing, S.L., Yeong, W.Y., and Wiria, F.E., Selective laser melting of titanium alloy with 50wt% tantalum: microstructure and mechanical properties, J. Alloys Compd., 2016, vol. 660, pp. 461–470.

Fischer, M., Joguet, D., Robin, G., Peltier, L., and Laheurte, P., In situ elaboration of a binary Ti–6Nb alloy by selective laser melting of elemental titanium and niobium mixed powders, Mater. Sci. Eng., C, 2016, vol. 62, pp. 852–859.

Vrancken, B., Thijs, L., Kruth, J.P., and Van Humbeeck, J., Microstructure and mechanical properties of a novel β titanium metallic composite by selective laser melting, Acta Mater., 2014, vol. 68, pp. 150–158.

Zhou, Y.L., Niinomi, M., and Akahori, T., Effects of Ta content on Young’s modulus and tensile properties of binary Ti–Ta alloys for biomedical applications, Mater. Sci. Eng., A, 2004, vol. 371, pp. 283–290.

Meier, H. and Haberland, C., Experimental Studies on Selective Laser Melting of Metallic Parts, Materialwiss. Werkstofftech., 2008, vol. 39, no. 9, pp. 665–670.

ASTM B855-06: Standard Test Method for Volumetric Flow Rate of Metal Powders Using Arnold Meter and Hall Funnel, West Conshohocken, PA: ASTM Int., 2006.

ASTM B703-05: Standard Test Method for Apparent Density of Powders Using Arnold Meter, West Conshohocken, PA: ASTM Int., 2005.

ASTM B527-06: Standard Test Method for Determination of Tap Density of Metallic Powders and Compounds, West Conshohocken, PA: ASTM Int., 2006.

Schmid, M., Levy, G., Amado, F., and Wegener, K., Flowability of powders for selective laser sintering (SLS) investigated by round robin test, in High Value Manufacturing: Advanced Research in Virtual and Rapid Prototyping, Boca Raton, FL: CRC Press, 2013, pp. 95–99.

ASTM D7481: Standard Test Methods for Determining Loose and Tapped Bulk Densities of Powders using a Graduated Cylinder, West Conshohocken, PA: ASTM Int., 2009.

Chatham, C.A., Long, T.E., and Williams, C.B., A review of the process physics and material screening methods for polymer powder bed fusion additive manufacturing, Prog. Polym. Sci., 2019, vol. 93, pp. 68–95.

Author information

Authors and Affiliations

Corresponding authors

Ethics declarations

The authors declare to have no conflict of interest.

About this article

Cite this article

Ahu Celebi, Gulizia, S., Doblin, C. et al. Characterization of Tantalum–Titanium Powders with Universal Powder Bed (UPB) System for Electron Beam Melting Process. Russ. J. Non-ferrous Metals 61, 346–353 (2020). https://doi.org/10.3103/S1067821220030050

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.3103/S1067821220030050