Abstract

The research results of the production of long deformed semi-fabricated products by sheet rolling and direct extrolling from aluminum-magnesium alloys with various scandium content are presented. Computer simulation and physical modeling methods are used and the results are verified by pilot testing. The choice of these materials as objects of research is due to the fact that aluminum alloys of the Al–Mg system doped with scandium have an increased corrosion resistance along with high strength. In this regard, the present work sets up a target of obtaining long deformed semi-fabricated products in the form of sheet metal, bars, and welding wire from Al–Mg alloys, including lean alloyed ones. For computer simulation, the DEFORM-3D software package is used to determine the rational conditions for the hot rolling of large ingots and the deformation modes of the direct extrolling of bars from the alloys under consideration. The technological and power parameters of these processes and the laws of their change are established and justified. The experimental results make it possible to identify marginal values of the force parameters during the physical modeling of the processes under study, as well as to study the structure and properties of deformed, annealed, and welded semi-fabricated products from the alloys under consideration. In addition, the material properties are determined in a quite wide range of temperature, speed, and deformation parameters variations. Based on the experimental and simulation results, recommendations are given for the industrial development of hot rolling of heavy gauge aluminum-magnesium ingots. For this purpose, technological solutions, regulations, and conditions for the production of deformed semi-fabricated products from these alloys are developed and batches of sheet metal with the required mechanical and corrosion properties are obtained.

Similar content being viewed by others

REFERENCES

Gorbunov, Yu.A., Application of products from aluminum alloys in the manufacture and repair of land and water transport in the Russian Federation, Tekhnol. Legk. Splavov, 2015, no. 1, pp. 87–92.

Bronze, A.V., Efremov, V.I., Plotnikov, A.D., and Chernyavsky, A.G., Alloy 1570C – a material for hermetic constructures of the perspective reusable products of RSC “Energia”, Kosm. Tekhn. Tekhnol., 2014, no. 4, pp. 62–67.

Filatov, Yu.A. and Plotnikov, A.D., Structure and properties of deformed semi–finished products from aluminum alloy 01570C of the Al–Mg–Sc system for the RSC “Energia” product, Tekhnol. Legk. Splavov, 2011, no. 2, pp. 15–26.

Orlov, G.A., Technological Processes of Metal Forming, Yekaterinburg: Ural Federal Univ., 2013.

Luts, A.R. and Suslina, A.A., Aluminium and Its Alloys, Samara: Samara State Technical Univ., 2013.

Belov, N.A., Phase Composition of Industrial and Advanced Aluminum Alloys, Moscow: MISIS, 2010.

Toropova, L.S., Eskin, D.S., Kharakterova, M.L., and Dobatkina, T.V., Advanced Aluminum Alloys Containing Scandium: Structure and Properties, Amsterdam: Gordon and Breach Sci. Publ., 1998.

Marquis, E.A. and Seidman, E.A., Nanoscale structural evolution of Al3Sc precipitates in Al (Sc) alloys, Acta Mater., 2001, vol. 49, pp. 1909–1919.

Fuller, C.B. and Seidman, D.N., Temporal evolution of the nanostructure of Al(Sc,Zr) alloys. Part II: coarsening of Al3(Sc1−xZrx) precipitates, Acta Mater., 2005, vol. 53, no. 20, pp. 5415–5428.

Ryset, J. and Ryum, N., Scandium in aluminum alloys, Int. Mater. Rev., 2005, vol. 50, no. 1, pp. 19–44.

Zhemchuzhnikova, D. and Kaibyshev, R., Effect of grain size on cryogenic mechanical properties of an Al–Mg–Sc alloy, Adv. Mater. Res., 2014, vol. 922, pp. 862–867.

Malopheyev, S., Kulitskiy, V., and Kaibyshev, R., Deformation structures and strengthening mechanisms in an Al–Mg–Sc–Zr alloy, J. Alloys Compd., 2017, vol. 698, pp. 957–966.

Pereiraa Pedro, Henrique, R., Wang Ying, Chun Huang Yi, and Langdon Terence, G., Influence of grain size on the flow properties of an Al–Mg–Sc alloy over seven orders of magnitude of strain rate, Mater. Sci. Eng. A, 2017, vol. 685, pp. 367–376.

Mondol, S., Alamb, T., Banerjee, R., Kumar, S., and Chattopadhyay, K., Development of a high temperature high strength Al alloy by addition of small amounts of Sc and Mg to 2219 alloy, Mater. Sci. Eng. A, 2017, vol. 687, pp. 221–231.

Shi Chunchang, Zhang Liang, Wu Guohua, Zhang Xiaolong, Chen Antao, and Tao Jiashen, Effects of Sc addition on the microstructure and mechanical properties of cast Al–3Li–1.5Cu–0.15Zr alloy, Mater. Sci. Eng. A, 2017, vol. 687, pp. 232–238.

Li Mengjia, Pan Qinglin, Shi Yunjia, Sun Xue, and Xiang Hao, High strain rate superplasticity in an Al–Mg–Sc–Zr alloy processed via simple rolling, Mater. Sci. Eng. A, 2017, vol. 687, pp. 298–305.

Buranova, Yu., Kulitskiy, V., Peterlechner, M., Mogucheva, A., Kaibyshev, R., Divinski, S., and Wilde, G., Al3(Sc, Zr)—based precipitates in Al-Mg alloy: effect of severe deformation, Acta Mater., 2017, vol. 53, no. 124, pp. 210–224.

Dovzhenko, I.N., Dovzhenko, N.N., Sidelnikov, S.B., and Konstantinov, I.L., 3D modelling of the large-capacity ingots of an Al–Mg system aluminium alloy doped with scandium rolling process, Non-Ferrous Met., 2017, no. 2, pp. 60–64.

Baranov, V.N., Sidelnikov, S.B., Frolov, V.F., Zenkin, E.Yu., Konstantinov, I.L., Voroshilov, D.S., Yakivyuk, O.V., and Belokonova, I.N., Investigation of mechanical properties of cold-rolled, annealed and welded semi-finished products from the test alloys of Al–Mg system, economically alloyed with scandium, IOP Conf. Ser.: Mater. Sci. Eng., 2018, vol. 411, no. 012015, pp. 1–5.

Baranov, V., Sidelnikov, S., Zenkin, E., Frolov, V., Voroshilov, D., Yakivyuk, O., Konstantinov, I., Sokolov, R., and Belokonova, I., Study of strength properties of semi-finished products from economically alloyed high-strength aluminium-scandium alloys for application in automobile transport and shipbuilding, Open Eng., 2018, no. 8, pp. 69–76.

Baranov, V., Sidelnikov, S., Zenkin, E., and Yakivyuk, O., Physical modeling technological regimes of production deformed semi–finished products from experimental aluminium alloys alloyed by scandium, Mater. Sci. Forum, 2018, vol. 918, pp. 54–62.

Mann, V.Kh., Sidelnikov, S.B., Konstantinov, I.L., Baranov, V.N., Dovzhenko, I.N., Voroshilov, D.S., Lopatina, E.S., Yakivyuk, O.V., and Belokonova, I.N., Modeling and investigation of the process of hot rolling of large-sized ingots from aluminum alloy of the Al‒Mg system, economically alloyed by scandium, Mater. Sci. Forum, 2019, vol. 943, pp. 58–65.

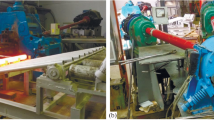

Sidelnikov, S.B., Yakivyuk, O.V., Baranov, V.N., Konstantinov, I.L., Dovzhenko, I.N., Lopatina, E.S., Voroshilov, D.S., Samchuk, A.P., and Frolov, V.A., Computer simulation, analysis of force and temperature-speed parameters of the process of combined machining of Al–Mg–Sc alloys, IOP Conf. Ser.: Mater. Sci. Eng., 2019, vol. 544, no. 012018, pp. 1–5.

Matveev, M.A., Numerical estimation of the probability of metal failure under hot plastic deformation by means of the Cockroft–Latham criterion, Vedomosti SPbPU.Estestv. Inzh. Nauki, 2017, vol. 23, no. 2, pp. 109–126.

Funding

This work was carried out under the project 03.G25.31.0265 “Development of Sparingly Doped High-Strength Al–Sc Alloys for Use in Automotive and Shipbuilding Industries” as part of the Program for the Implementation of Complex Projects for the Creation of High-Tech Production, approved by Decree of the Government of the Russian Federation of April 9, 2010, No. 218.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

The authors declare that they have no conflict of interest.

Additional information

Translated by A. Kolemesin

About this article

Cite this article

Sidelnikov, S.B., Yakivyuk, O.V., Baranov, V.N. et al. Developing, Simulating, and Researching a Production Process of Long Deformed Semi-Fabricated Aluminum–Magnesium Products with a Varying Scandium Content. Russ. J. Non-ferrous Metals 61, 81–88 (2020). https://doi.org/10.3103/S1067821220010150

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.3103/S1067821220010150