Abstract

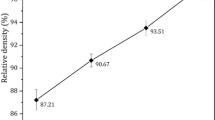

The possibility of increasing the mechanical properties of the ceramic material of the TaSi2–SiC system by reinforcing it with silicon carbide nanofibers forming in situ in the combustion wave of the SHS system is investigated. To fabricate nanofibers, as well as to increase the exothermicity of reaction mixtures, an energetic polytetrafluoroethylene (PTFE) additive C2F4 was applied. The 70%TaSi2 + 30%SiC ceramic, in which silicon carbide is situated in two types of morphology—in the form of rounded grains and discrete nanofibers—was fabricated with the help of self-propagating high-temperature synthesis when using the mechanical activation of initial reaction mixtures. Reinforced ceramic samples sintered using hot pressing have a relative density up to 98%, hardness of 19.0–19.2 GPa, and crack resistance of 7.5–7.8 MPa m1/2 (which noticeably exceeds the crack resistance of the ceramics of the close composition formed without the PTFE additive).

Similar content being viewed by others

REFERENCES

Properties and Applications of Silicon Carbide, Rosario Gerhardt, Ed., IntechOpen, 2011. https://doi.org/10.5772/615.

Moskovskikh, D.O., Lin, Y-C., Rogachev, A.S., McGinn, P.J., and Mukasyan, A.S., Spark plasma sintering of SiC powders produced by different combustion synthesis routes, J. Eur. Ceram. Soc., 2015, vol. 35, no. 2, pp. 477–486.

Vorotilo, S., Potanin, A.Y., Iatsyuk, I.V., and Levashov, E.A., SHS of silicon-based ceramics for the high-temperature applications, Adv. Eng. Mater., 2018, vol. 20, no. 8, p. 1800200.

Chen, P., Jing, S., Chu, Y., and Rao, P., Improved fracture toughness of CNTs/SiC composites by HF treatment, J. Alloys and Compd., 2018, vol. 730, pp. 42–46.

Li, Q., Zhang, Y., Gong, H., Sun, H., Li, W., Ma, L., and Zhang, Y., Enhanced fracture toughness of pressureless-sintered SiC ceramics by addition of graphene, J. Mater. Sci. Technol., 2016, vol. 32, no. 7, pp. 633–638.

Vorotilo, S., Levashov, E.A., Kurbatkina, V.V., Kovalev, D.Yu., and Kochetov, N.A., Self-propagating high-temperature synthesis of nanocomposite ceramics TaSi2–SiC with hierarchical structure and superior properties, J. Eur. Ceram. Soc., 2018, vol. 38, no. 2, pp. 433–443.

Du, S.X., Zhang, K., Wen, M., Ren, P., Meng, Q.N., Zhang, Y.D., and Zheng, W.T., Crystallization of SiC and its effects on microstructure, hardness and toughness in TaC/SiC multilayer films, Ceram. Int., 2018, vol. 44, pp. 613–621.

Luo, H., Chen, W., Zhou, W., Long, L., Deng, L., Xiao, P., and Li, Y., Carbon fiber/Si3N4 composites with SiC nanofiber interphase for enhanced microwave absorption properties, Ceram. Int., 2017, vol. 43, no. 15, pp. 12328–12332.

Ayral, R.M., Rouessac, F., and Massoni, N., Combustion synthesis of silicon carbide assisted by a magnesium plus polytetrafluoroethylene mixture, Mater. Res. Bull., 2009, vol. 44, no. 11, pp. 2134–2138.

Nersisyan, G.A., Nikogosov, V.N., Kharatyan, S.L., and Merzhanov, A.G., Chemical transformation mechanism and combustion regimes in the system silicon-carbonfluoroplast, Combust. Explos. Shock Waves, 1991, vol. 27, no. 6, pp. 720–724.

Anstis, G.R., Chantikul, P., Lawn, B.R., and Marshal, D.B., A critical evaluation of indentation techniques for measuring fracture toughness: I. Direct crack measurements, J. Amer. Ceram. Soc., 1981, vol. 64, pp. 533–538.

Liu, G., Chen, K., and Li, J., Combustion synthesis: An effective tool for preparing inorganic materials, Scripta Mater., 2018, vol. 157, pp. 167–173.

Yang, Z., Li, Z., Ning, T., Zhang, M., Yan, Y., Zhang, D., and Cao, G., Microwave dielectric properties of B and N co-doped nanopowders prepared by combustion synthesis, J. Alloys Compd., 2019, vol. 777, pp. 1039–1043. https://doi.org/10.1016/j.jallcom.2018.11.067.

Dąbrowska, A., Bzymek, A., and Huczko, A., In situ diagnostics of the SiC nanostructures growth process, J. Crystal Growth, 2014, vol. 401, pp. 376–380.

Chu, A., Zhang, D., Guo, S., and Qu, X., Polyacrylamide-assisted combustioncarbothermal synthesis of well-distributed SiC nanowires, Ceram. Int., 2015, vol. 41, no. 10, Pt. B, pp. 14585–14591.

Zheng, C.-S., Yan, Q.-Z., and Xia, M., Combustion synthesis of SiC/Si3N4–NW composite powders: The influence of catalysts and gases, Ceram. Int., 2012, vol. 38, no. 6, pp. 4549–4554.

Potanin, A.Yu., Zvyagintseva, N.V., Pogozhev, Yu.S., Levashov, E.A., Rupasov, S.I., Shtansky, D.V., Kochetov, N.A., and Kovalev, D.Yu., Silicon carbide ceramics SHSproduced from mechanoactivated Si–C–B mixtures, Int. J. SHS, 2015, vol. 24, no. 3, pp. 119–127.

Iatsyuk, I.V., Potanin, A.Yu, Rupasov, S.I., and Levashov, E.A., Kinetics and high-temperature oxidation mechanism of ceramic materials in the ZrB2–SiC–MoSi2 system, Russ. J. Non-Ferrous Met., 2018, vol. 59, no. 1, pp. 76–81.

ACKNOWLEDGMENTS

This study was supported by the Russian Scientific Foundation, project no. 14-19-00273-P.

Author information

Authors and Affiliations

Corresponding authors

Additional information

Translated by N. Korovin

About this article

Cite this article

Vorotilo, S., Polosova, E.D. & Levashov, E.A. Peculiarities of the Synthesis of High-Temperature TaSi2–SiC Ceramics Reinforced in situ by Discrete Silicon Carbide Nanofibers. Russ. J. Non-ferrous Metals 60, 169–172 (2019). https://doi.org/10.3103/S1067821219020159

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.3103/S1067821219020159