Abstract

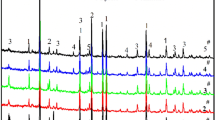

Alumina refineries in China continue to face challenges in achieving clean and efficient utilization of high-sulfur bauxite. Disulfide ions, \({\text{S}}_{2}^{{2 - }},\) in FeS2 can be considered as active components in the Bayer process for alumina production, but they lead to corrosion of the equipment used in the processing of bauxite. Our research investigates the transformation rules of \({\text{S}}_{2}^{{2 - }}\) in bauxite during roasting, and the impact of digestion conditions on the digestion efficiency of the roasted ore and \({\text{S}}_{2}^{{2 - }}\) distribution. The results revealed that the onset temperature of kaolinite dehydration was approximately 700°C. The standard Gibbs free energy of all other reactions, including pyrite oxidation at 500–750°C, was negative. Dehydration began at 433.0°C, attained its maximum rate at 508.5°C, and ended at 593.0°C. Roasting pre-treatment removed approximately 95% of the sulfide, promoted digestion of alumina in bauxite, and reduced the active sulfur content by ~27%.

Similar content being viewed by others

REFERENCES

Li, X., Li, C., Zhou, Q. et al., Interaction of sodium sulfide with silica-containing minerals in sodium aluminate solution, Int. J. Min. Proc., 2015, vol. 137, pp. 9–14.

Li, Z.Y., Zhang, N.B., and He, R.D., Research on the new method of desulfurizing in producing alumina with exploitable sulfur-containing and high grade bauxite, J. Guizhou Univ. Technol. (Nat. Sci. Edit.), 2007, no. 2, pp. 29–32.

Wang, Y.Y., Zhang, T.A. and Chen, X., Effects of microwave roasting on leaching behavior of diaspore ore, Chin. J. Proc. Eng., 2004, no. 2, pp. 317–321.

Zhao, H.Q., Yang, Z.Y., and Liu, H.B., Investigation on kinetics of bauxite’s digestion improved by pre-roasting process, Cons. Utiliz. Miner. Res., 1998, no. 6, pp. 28–32.

Lv, G.Z., Zhang, T.A., Zhu, X.F., et al., Calcification–carbonation method for cleaner alumina production and CO2 utilization, JOM, 2014, no. 9, pp. 1616–1621.

Liu, L.R., Yu, Q.B., Lu, Z.W., et al., The impact of logistics on energy consumption in sintering process of alumina production, Nonferrous Met., 2003, no. 2, pp. 51–54.

Padilla, R., Vega, D., and Ruiz, M.C., Pressure leaching of sulfidized chalcopyrite in sulfuric acid–oxygen media, Hydrometallurgy, 2007, nos. 1–2, pp. 80–88.

Zhang, N.B., Jing, H.S., and Wu, X.X., Research on disposing of sulfur of high grade bauxite containing sulfur in Guizhou, Light Met., 2007, no. 7, pp. 7–10.

Hind, R.A. Bhargava, K.S. and Stephen, C., The surface chemistry of Bayer process solids: a review, Colloids Surf. A: Physicochem. Eng. Asp., 1999, nos. 1–3, pp. 359–374.

He, R.D., Hu, S.C., and Li, Z.Y., Discussion on the method of Hydrometallurgical Desulfurizing during Producing Alumina with High Grade Bauxite Containing Sulfur, Hydromet. China, 2004, vol. 23, pp. 66–68.

Liu, Y., Lin, C.X., and Wu, Y.G., Characterization of red mud derived from a combined Bayer process and bauxite calcination method, J. Hazard. Mater., 2007, nos. 1–2, pp. 255–261.

Qi, Y.Q., et al., Desulfurization of coal through pyrolysis in a fluidized-bed reactor under nitrogen and 0.6% O2–N2 atmosphere, Fuel Energy Abstr., 2004, no. 6, pp. 705–712.

Wang, X.M., Zhang, T.A., Lv, G.Z., et al., Flotation process for desulfurization of high sulfur bauxite, Chin. J. Rare Met., 2009, no. 5, pp. 728–732.

Wang, X.M., Zhang, T.A., Lv, G.Z., et al., Flotation desulfurization of high-sulfur bauxite with butyl xanthate as collector, Chin. J. Proc. Eng., 2009, no. 3, pp. 498–502.

Lv, G.Z., Zhang, T.A., Bao, L., Dou, Z.H., and Zhang, W.G., Roasting pretreatment of high-sulfur bauxite, Chin. J. Proc. Eng., 2008, no. 5, pp. 892–896.

Lv, G.Z., Zhang, T.A., Bao, L., et al., Roasting pretreatment of high-sulfur Bauxite and Digestion Performance of Roasted Ore, Chin. J. Nonferrous Met., 2009, no. 9, pp. 1684–1689.

Lv, G.Z., Zhang, T.A., Liu, Y., et al., Roasting pretreatment of high sulfur bauxite of China, TMS Light Met, 2009, pp. 75–81.

Li, Q., Xu, D.L., Chen, Y.X., et al., Decomposition of ammonium sulfate residue in a high solid/gas ratio suspension state with an industrial-scale reactor system (production line), Particuology, 2015, vol. 22, pp. 107–113.

Chen, Y.X., Zhao, B., Jiu, S.W., et al., Desulfurization roasting of high sulfur bauxite in suspended state, J. Central South Univ. (Sci. Technol.), 2016, no. 8, pp. 2577–2583.

X.J., Liu, Y.X., Chen, B., Zhao, et al., Experimental investigation on roasting desulfurization of high-sulfur bauxite, Min. Metall. Eng., 2017, no. 2, pp. 112–115.

ACKNOWLEDGMENTS

We acknowledge the National Natural Science Foundation of China (nos. U1710257, U1402271, U1202274), Fundamental Research Funds for the Central Universities of China (nos. N140203005, N140204015), and State Key Laboratory of Pressure Hydrometallurgical Technology of Associated Nonferrous Metal Resources (YY2016006).

Author information

Authors and Affiliations

Corresponding authors

Additional information

The article is published in the original

About this article

Cite this article

Dong Lu, Lv, G., Zhang, TA. et al. Roasting Pre-Treatment of High-Sulfur Bauxite for Sulfide Removal and Digestion Performance of Roasted Ore. Russ. J. Non-ferrous Metals 59, 493–501 (2018). https://doi.org/10.3103/S1067821218050097

Received:

Published:

Issue Date:

DOI: https://doi.org/10.3103/S1067821218050097