Abstract

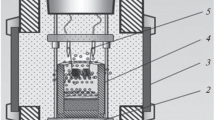

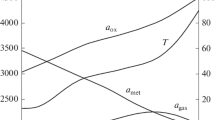

A review of publications on the structure, properties, fabrication methods, and application fields of materials based on the Cr2AlC MAX phase is given. It is noted that the most promising method of formation of such materials is self-propagating high-temperature synthesis (SHS), one of the directions of which is SHS metallurgy. A powder mixture of chromium III and chromium VI oxides of the analytical grade, aluminum of ASD-1 grade, and carbon is used as the base charge in investigations. The adiabatic combustion temperature and composition of final products is calculated using the THERMO special program. Experiments were performed in an SHS reactor with volume V = 3 dm3 under the initial pressure of inert gas (Ar) P0 = 5 MPa. The influence of the ratio of initial reagents on SHS parameters (the combustion rate, pressure increment, and yield of the target product), composition, and microstructure of target products is investigated experimentally. A scientific approach of the formation of cast materials in the Cr–Al–C system consisting of the Cr2AlC MAX phase and phases Cr3C2 and Cr5Al8 by the SHS metallurgy method is developed. The structural-phase states of target products are studied. It is established experimentally that, varying the content of initial reagents (aluminum and carbon) in the charge, it is possible to substantially affect the synthesis regularities, composition, and microstructure of final products. An increase in the content of the Cr2AlC MAX phase in the final product and a decrease in the Cr5Al8 content occur with an increase in the carbon content (above stoichiometric) in the initial mixture. An increase in the aluminum content (above stoichiometric) in the initial mixture leads to an increase in the content of the Cr2AlC MAX phase in the final product and a decrease in the content of the Cr3C2 phase.

Similar content being viewed by others

REFERENCES

Barsoum, M.W. and Raghy, T., The MAX phases: Unique new carbide and nitride materials, Amer. Sci., 2001, vol. 89, no. 4, pp. 336–345.

Tzenov, N.V. and Barsoum, M.W., Synthesis and characterization of Ti3AlC1.8, J. Amer. Ceram. Soc., 2000, vol. 83, no. 4, pp. 825–832.

Barsoum, M.W. and Radovic, M., Elastic and mechanical properties of the MAX phases, Annu. Rev. Mater. Res., 2011, vol. 41, pp. 195–227.

Li, H., Li, S., and Zhou, Y., Cyclic thermal shock behavior of a Cr2AlC ceramic, Mater. Sci. Eng. A, 2014, vol. 607, pp. 525–529.

Ying, G., He, X., Li, M, Du, S., Han, W., and He, F., Synthesis and mechanical properties of high-purity Cr2AlC ceramic, Mater. Sci. Eng. A, 2011, vol. 528, pp. 2635–2640.

Xiao, Li.O., Li, S.B., Song, G., and Sloof, W.G., Synthesis and thermal stability of Cr2AlC, J. Eur. Ceram. Soc., 2011, vol. 31, pp. 1497–1502.

Eklund, P., Beckers, M., Jansson, U., Högberg, H., and Hultman, L., The Mn+1AXn phases: Materials science and thin-film processing, Thin Solid Films, 2010, vol. 518, no. 8, pp. 1851–1878.

Frodelius, J., Sonestedt, M., Bjorklund, S., Palmquist, J., Stiller, K., Högberg, H., and Hultman, L., Ti2AlC coatings deposited by high velocity oxy-fuel spraying, Surf. Coat. Technol., 2008, vol. 202, pp. 5976–5981.

Pasumarthi, V., Chen, Y., Bakchi, S.R., and Agarwal, A., Reaction synthesis of Ti3SiC2 phase in plasma sprayed coating, J. Alloy Compd., 2009, vol. 484, pp. 113–117.

Verhoturov, A.D., Podchernyaeva, I.A., Pryadko, L.F., and Egorov, F.F., Elektrodnye materialy dlya elektroiskrovogo legirovaniya (Electrode Materials for Spark Alloying), Moscow: Nauka, 1988.

Zamulaeva, E.I., Levashov, E.A., Sviridova, T.A., Shvyndina, N.V., and Petrzhik, M.I., Electrospark deposition of protective coatings based on MAX-phases, Izv. Vyssh. Uchebn. Zaved. Poroshk. Metall. Funkts. Pokryt., 2013, no. 3, pp. 73–81.

Gitlevich, A.E., Mikhailov, V.V., Parkanskii, N.Ya., and Revutskii, V.M., Elektroiskrovoe legirovanie metallicheskikh pokrytii (Electric Spark Alloying of Metal Surfaces), Kishinev: Shtinitsa, 1985.

Li, S.B., Yu, W.B., Zhai, H.X., Song, G.M., Sloof, W.G., and Zwaag, S., Mechanical properties of low temperature synthesized dense and fine-grained Cr2AlC ceramics, J. Eur. Ceram. Soc., 2011, no. 31, pp. 217–224.

Zhou, W.B., Mei, B.C., and Zhu, J.Q., On the synthesis and properties of bulk ternary Cr2AlC ceramics, Mater. Sci.-Pol., 2009, vol. 27, no. 4/1, pp. 973–980.

Zhu, J., Jiang, H., Wang, F., Yang, C., and Xiao, D., Synthesis, microstructure and mechanical properties of Cr2AlC, J. Eur. Ceram. Soc., 2014, vol. 34, pp. 4137–4144.

Duan, X., Shen, L., Jia, D., Zhou, Y., Zwaag, S., and Sloof, W.G., Synthesis of high-purity, isotropic or textured Cr2AlC bulk ceramics by spark plasma sintering of pressure-less sintered powders, J. Eur. Ceram. Soc., 2015, vol. 35, pp. 1393–1400.

Merzhanov, A.G., Samorasprostranyayuschiisya vysokotemperaturnyi sintez. Fizicheskaya khimiya. Sovremennye problemy (Self-Propagating High-Temperature Synthesis. Physical Chemistry. Modern Problems), Moscow: Khimiya, 1983.

Levashov, E.A., Rogachev, A.S., Kurbatkina, V.V., Maksimov, Yu.M., and Yukhvid, V.I., Perspektivnye materialy i tekhnologii samorasprostranyayuschegosya vysokotemperaturnogo sinteza (Advanced Materials and Technologies of Self-Propagating High-Temperature Synthesis), Moscow: MISiS, 2011.

Gorshkov, V.A., Kachin, A.R., and Yukhvid, V.I., SHS metallurgy of cast Cr3C2–NiAl composite material and protective coatings based on it, Persp. Mater., 2014, no. 10, pp. 60–67.

Miloserdov, P.A., Gorshkov, V.A., and Yukhvid, V.I., High-temperature synthesis of cast Cr2AlC at an inert gas overpressure, Inorg. Mater., 2013, vol. 49, no. 8, pp. 781–785.

ACKNOWLEDGMENTS

We thank A.E. Sychev, acting head of Laboratory no. 8 at the Institute of Structural Macrokinetics of the Russian Academy of Sciences, for participating in the preparation of the material for the article.

Author information

Authors and Affiliations

Corresponding authors

Additional information

Translated by N. Korovin

About this article

Cite this article

Gorshkov, V.A., Miloserdov, P.A., Sachkova, N.V. et al. SHS Metallurgy of Cr2AlC MAX Phase-Based Cast Materials. Russ. J. Non-ferrous Metals 59, 570–575 (2018). https://doi.org/10.3103/S106782121805005X

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.3103/S106782121805005X