Abstract

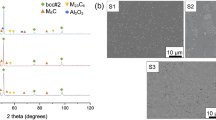

The microstructure and mechanical characteristics of the samples of medium-grained (WC‒8Co), submicron (WC–8Co–1Cr3C2), and ultrafine (WC–8Co–0.4VC–0.4Cr3C2) hard alloys formed by liquid-phase sintering of powders of corresponding dispersity are investigated. It is shown that the alloy hardness increases from 1356 to 1941 HV with a decrease in the average grain size from 1.65 to 0.37 μm. The comparison with the published data shows that alloys considered in this study are no worse than analogs formed by sintering under a pressure, hot pressing, and induction and spark plasma sintering by hardness and fracture toughness. Herewith, the flexural strength of alloys prepared by liquid-phase sintering is lower by a factor of 1.5–2.5 than that of alloys formed by sintering under a pressure or pressing because of the presence of pores, the maximal diameter of which is evaluated as 40 μm. An analysis of the results and published data for the correspondence of theoretical regularities is performed. It is shown that the dependences of hardness, fracture toughness, and strength on the average grain size of formed alloys and their analogs in general correspond to traditional regularities based on the Hall–Petch and Orowan–Griffiths laws, despite the presence of theoretical prerequisites for the deviation from them.

Similar content being viewed by others

Notes

Photographs using a scanning microscope were formed at the Far Eastern Electronic Microscopy Center on the basis of the IBM of the Far East Branch of the Russian Academy of Sciences.

REFERENCES

Grigor’ev, S.N. and Tabakov, V.P., Tekhnologicheskie metody povysheniya iznosostoikosti kontaktnykh ploshchadok rezhushchego instrumenta (Manufacturing Methods of Increasing the Wear Resistance of Contact Areas of the Cutting Tool), Staryi Oskol: TNT, 2011.

Geoffrey, E. and Spriggs, A., History of fine grained hardmetal, Int. J. Refract. Met. Hard Mater., 1995, vol. 13, pp. 241–255.

Panov, V.S. and Zaitsev, A.A., Tendencies in the development of the technology of ultradispersed and nanodimensional W–Co hard alloys, Izv. Vyssh. Uchebn. Zaved. Poroshk. Metall. Funkts. Pokryt., 2014, no. 3, pp. 38–48.

Zak Fang, Z., Xu Wang, Taegong Ryu, Kyu Sup Hwang, and Sohn, H.Y., Synthesis, sintering, and mechanical properties of nanocrystalline cemented tungsten carbide: A review, Int. J. Refract. Met. Hard Mater., 2009, vol. 27, pp. 288–299.

Shatov, A.V., Ponomarev, S.S., and Firstov, S.A., Fracture and strength of hardmetals at room temperature, Compr. Hard Mater., 2007, vol. 1, pp. 38–43.

Mukhopadhyay, A. and Basu, B., Consolidation-microstructure-property relationships in bulk nanoceramics and ceramic nanocomposites: A review, Int. Mater. Rev., 2007, vol. 52, no. 5, pp. 257–288.

Gille, G., Szesny, B., Dreyer, K., Berg, H., Schmidt, J., Gestrich, T., and Leitner, G., Submicron and ultrafine grained hardmetals for microdrills and metal cutting inserts, Int. J. Refract. Met. Hard Mater., 2002, vol. 20, pp. 3–22.

Hiroyuki Saito, Akira Iwabuchi, and Tomoharu Shimizu, Effects of Co content and WC grain size on wear of WC cemented carbide, Wear, 2006, vol. 261, pp. 126–132.

Jia, K. and Fischer, T.E., Sliding wear of conventional and nanostructured cemented carbides, Wear, 2001, vols. 203–204, pp. 310–318.

Krakhmalev, P.V., Adeva Rodil, T., and Bergstrom, J., Influence of microstructure on the abrasive edge wear of WC–Co hardmetals, Wear, 2007, vol. 263, pp. 240–245.

Allen, C., Sheen, M., Williams, J., and Pugsley, V.A., The wear of ultrafine WC–Co hard metals, Wear, 2001, vol. 250, pp. 604–610.

Dvornik, M.I. and Zaitsev, A.V., Comparative analysis of the wear resistance of WC–8Co–1Cr3C2 and traditional hard alloys under dry friction, Perspekt. Mater., 2015, no. 5, pp. C. 34–41.

Dvornik, M.I., Mokritskii, B.Ya., and Zaitsev, A.V., Comparative analysis of microabrasive durability of traditional carbide and carbide submicron WC–8Co–1Cr3C2, Vopr. Materialoved., 2015, no. 1 (81), pp. 45–51.

Ken Brookes, What’s in a name? Nano Experts Seek Definitions, 2006, vol. 6, pp. 24–26.

Zhi-Hui Xu and John Agren, A modified hardness model for WC–Co cemented carbides, Mater. Sci. Eng. A, 2004, vol. 386, pp. 262–268.

Engqvist, H., Jacobson, S., and Axen, N., A model for the hardness of cemented carbides, Wear, 2002, vol. 252, pp. 384–393.

Makhele-Lecala, L., Luiyckx, S., and Nabarro, F.R.N., Semiempirical relationship between hardness, grain size and mean free path of WC–Co, Int. J. Refract. Met. Hard Mater., 2001, vol. 19, pp. 245–249.

Seung I. Cha, Kyong H. Lee, Ho J. Ryu, and Soon H. Hong, Analytical modeling to calculate the hardness of ultrafine WC–Co cemented carbides, Mater. Sci. Eng. A, 2008, vol. 489, pp. 234–244.

Jia, K., Fischer, T.E., and Gallois, B., Microstructure, hardness and toughness of nanostructured and conventional WC–Co composites, Nanostruct. Mater., 1998, vol. 10, no. 5, pp. 875–891.

Binghai Liu, Yue Zhang, and Shixi Ouyang, Study on the relation between structural parameters and fracture strength of WC–Co cemented carbides, Mater. Chem. Phys., 2000, vol. 62, no. 1, pp. 35–43.

Chongbin Wei, Xiaoyan Song, Jun Fu, Xuemei Liu, Haibin Wang, Yang Gao, and Yao Wang, Simultaneously high fracture toughness and transverse rupture strength in ultrafine cemented carbide, Cryst. Eng. Comm., 2013, vol. 15, pp. 3305–3307.

Leon L. Shawa, Hong Luob, Yang Zhong, WC–18 wt % Co with simultaneous improvements in hardness and toughness derived from nanocrystalline powder, Mater. Sci. Eng. A, 2012, vol. 537, pp. 39–48.

Wu Chong-hu and Zhang Tai-quan, Formation mechanisms of microstructure imperfections and their effects on strength in submicron cementer carbide, Int. J. Refract. Met. Hard Mater., 2013, vol. 40, pp. 8–13.

Kurlov, A.S., Rempel’, A.A., Leenaers, A., and Van Der Bergh, S., Flexural strength and microhardness of WC–8% Co hard alloys based on powders of different dispersity, Materialovedenie, 2009, no. 4, pp. 18–21.

Zhikang Zak Fang, Correlation of transverse rupture strength of WC–Co with hardness, Int. J. Refract. Met. Hard Mater., 2005, vol. 23, no. 2, pp. 119–127.

Sherif El-Eskandarany, M., Amir A. Mahday, Ahmed, H.A., and Amer, A.H., Synthesis and characterizations of ball-milled nanocrystalline WC and nanocomposite WC–Co powders and subsequent consolidations, J. Alloys Compd., 2000, vol. 312, pp. 315–325.

Hwan-Cheol Kim, In-Jin Shon, Jin-Kook Yoon, and Jung-Mann Doh, Consolidation of ultra fine WC and WC–Co hard materials by pulsed current activated sintering and its mechanical Properties, Int. J. Refract. Met. Hard Mater., 2007, vol. 25, no. 1, pp. 46–52.

Hwan Cheol Kim, In Kyoon Jeong, In Jin Shon, In Yong Ko, and Jung Mann Doh, Fabrication of WC–8 wt % Co hard materials by two rapid sintering processes, Int. J. Refract. Met. Hard Mater., 2007, vol. 25, no. 4, pp. 336–340.

Friederichs, J.W., US Patent 5368628, 2000.

Panov, V.S., Tekhnologiya i svoistva spechennykh tverdykh splavov i izdelii iz nikh (Technology and Properties of Sintered Hard Alloys and Wares Made of Them), Moscow: MISiS, 2001.

Tret’yakov, V.I., Osnovy metallovedeniya i tekhnologii proizvodstva spechennykh tverdykh splavov (Fundamentals of Metallurgy and Technology of Sintered Hard Alloys), Moscow: Metallurgiya, 1976.

Dvornik, M.I., Zaitsev, A.V., and Ershova, T.B., Increasing strength and hardness of submicron WC–8% Co–1% Cr3C2 hard alloy due to addition carburization during sintering, Vopr. Materialoved., 2011, no. 4 (68), pp. 81–88.

Shetty, D.K., Wright, I.G., Mincer, P.N., and Clauer, A.H., Indentation fracture of WC–Co cermets, J. Mater. Sci., 1985, vol. 20, pp. 1873–1882.

Yamamoto, T., Ikuhara, Y., Watanabe, T., Sakuma, T., Taniuchi, Y., Okada, K., and Tanase, T., High resolution microscopy study in Cr3C2-doped WC–CO, J. Mater. Sci., 2001, vol. 36, pp. 3885–3890.

Yamamoto, T., Ikuhara, Y., and Sakuma, T., High resolution transmission electron microscopy study in VC-doped WC–Co compound, Sci. Technol. Adv. Mater., 2000, vol. 1, pp. 97–104.

Yigao Yuan, Xiaoxiao Zhang, Jianjun Ding, and Jun Ruan, Measurement of WC grain size in ultrafine grained WC–Co cemented carbides, Appl. Mech. Mater., 2013, vols. 278–280, pp. 460–463.

Chernyavskii, K.S. and Travushkin, G.G., Modern notions on the relation of the structure and strength of WC–Co hard alloys (review), Probl. Prochn., 1980, no. 4, pp. 11–19.

Chaporova, I.N. and Chernyavskii, K.S., Struktura spechennykh tverdykh splavov (Structure of Sintered Hard Alloys), Moscow: Metallurgiya, 1975.

Exner, H.E. and Fischmeister, H.F., Structure of sintered tungsten carbide–cobalt alloys, Arch. Eisenhuttenwesen, 1966, vol. 37, pp. 417–426.

Lee, H.C. and Gurland, J., Hardness and deformation of cemented tungsten carbide, Mater. Sci. Eng., 1978, vol. 33, no. 1, pp. 125–133.

Sigl, L.S. and Fischmeister, H.F., On the fracture toughness of cemented carbides, Acta Metal., 1988, vol. 36, no. 4, pp. 887–891.

Luyckx, S. and Love, A., The dependence of the contiguity of WC on Co content and its independence from WC grain size in WC–Co alloys, Int. J. Refract. Met. Hard Mater., 2006, vol. 24, pp. 75–79.

Felten, F., Schneider, A., and Sadowski, T., Estimation of R-curve in WC/Co cermet by CT test, Int. J. Refract. Met. Hard Mater., 2008, vol. 26, pp. 55–60.

Cahal McVeigh and Wing Kam Liu, Multiresolution modeling of ductile reinforced brittle composites, J. Mech. Phys. Sol., 2009, vol. 57, pp. 244–267.

Dvornik, M.I. and Mikhailenko, E.A., Modeling of the spread of cracks in submicron and nanostructured hard alloys, Mekh. Kompoz. Mater. Pokr., 2014, vol. 20, no. 1, pp. 197–210.

Mandel, K., Kruger, L., and Schimpf, C., Study on parameter optimization for field-assisted sintering of fully-dense, near-nano WC–12Co, Int. J. Refract. Met. Hard Mater., 2014, vol. 45, pp. 153–159.

Godse, R. and Gurland, J., Applicability of the critical strain fracture criterion to WC–Co hard metals Pt. 2, Mater. Sci. Eng. A, 1988, vols. 105–106, pp. 331–336.

Osterstock, F. and Chermant, J.-L., Some aspects of the fracture of WC–Co composites, Sci. Hard Mater., 1983, pp. 615–629.

ACKNOWLEDGMENTS

This study was supported by grant no. 9.251.2014/K, project code 251.

Author information

Authors and Affiliations

Corresponding authors

Additional information

Translated by N. Korovin

About this article

Cite this article

Dvornik, M.I., Zaitsev, A.V. Variation in Strength, Hardness, and Fracture Toughness in Transition from Medium-Grained to Ultrafine Hard Alloy. Russ. J. Non-ferrous Metals 59, 563–569 (2018). https://doi.org/10.3103/S1067821218050024

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.3103/S1067821218050024