Abstract

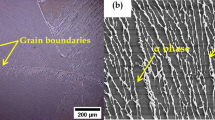

Abstract—Regularities of the formation of ultrafine-grained (UFG) and submicrocrystalline (SMC) structures in new nickel-free low-modulus Ti–Nb–Mo–Zr titanium β alloys under the action of plastic deformation have been studied. Temperature–time ranges of the development of dynamic recrystallization processes under the simultaneous action of temperature and plastic deformation are determined. A type-II recrystallization diagram of the Ti–28Nb–8Mo–12Zr alloy is constructed and analyzed. It is shown using scanning electron microscopy and the electron backscatter diffraction method that the UFG structure with an average grain size of no more than 7 μm and high fraction of high-angle grain boundaries is formed in the investigated alloys as a result of longitudinal rolling, followed by annealing for quenching. It is found that the formation of the UFG structure leads to a significant increase in the strength and plastic characteristics of these alloys. The regularities of the formation of UFG and SMC structures in titanium β alloys Ti–28Nb–8Mo–12Zr and industrial VT30 under the action of plastic deformation by the helical rolling method are studied. It is shown that the helical rolling of the VT30 alloy leads to the formation of the homogeneous UFG state as opposed to the Ti–28Nb–8Mo–12Zr alloy, where this method causes structure softening with micropores and microcracks formed in the central region. It is possible to form a nanostructured state with an average grain size of about 100 nm in Ti–Nb–Mo–Zr titanium β alloys using the high-pressure torsion method.

Similar content being viewed by others

References

Kolobov, Yu.R., Nanotechnologies for the formation of medical implants based on titanium alloys with bioactive coatings, Nanotechnol. Russ., 2009, vol. 4, nos. 11–12, pp. 758–775.

Stráskýa, J., Harcubaa, P., Václavováa, K., Horváth, K., Landa, M., Srba, O., and Janeček, M., Increasing strength of a biomedical Ti–Nb–Ta–Zr alloy by alloying with Fe, Si and O. J. Mechan. Behav. Biomed. Mater., 2017, vol. 71, pp. 329–336.

Wong, J.Y. and Bronzino, J.D., Biomaterials, Boca Raton: CRC, Taylor & Francis, 2007.

Gunawarman, B., Niinomi, M., Akahori, T., Souma, T., Ikeda, M., and Tada, H., Mechanical properties and microstructure of low cost β-titanium alloys for healthcare applications. Mater. Sci. Eng. C, 2005, vol. 25, no. 3, pp. 304–311.

Geetha, M., Singh, A.K., Asokamani, R., and Gogia, A.K., Ti based biomaterials, the ultimate choice for orthopedic implants: A review, Progr. Mater. Sci., 2009, vol. 54, pp. 397–425.

Yaszemski, M.J., Trantolo, D.J., Lewandrowski, K., and Hasirci, V., Biomaterials in Orthopedics, New York: Marcel Dekker, 2004.

Long, Marc and Rack, H.J., Titanium alloys in total joint replacement—material science perspective, Biomaterials, 1998, vol. 19, pp. 1621–1639.

Epple, M., Biomaterialien und Biomineralisation, Wiesbaden: Vieweg + Teubner, 2003.

Peterson, D.R. and Bronzino, J.D., Biomechanics Principles and Applications, Boca Raton: CRC, Taylor & Francis, 2008.

Niinomi, M., Nakai, M., and Heida J., Development of new metallic alloys for biomedical applications, Acta Biomater., 2012, vol. 8, no. 11, pp. 3888–3903.

Leyens, C. and Peter, M., Titanium and Titanium Alloys. Fundamentals and Applications, Weinheim: Wiley, 2003.

Ranter, B.D., Hoffman, A.S., Schoen, F.J., and Lemons, J.E., Biomaterials Science: An Introduction to Materials in Medicine, San Diego: Elsevier, 2004, 2nd ed.

Hanawa, T., Hiromoto, S., and Yamamoto, A., Metallic biomaterials in body fluid and their surface modification, in Structural Biomaterials for the 21 Century, New Orleans: TMS, 2001, pp. 145–154.

Niinomi, M., Recent research and development in titanium alloys for biomedical applications and healthcare goods, Sci. Technol. Adv. Mater., 2003, vol. 4, pp. 445–454.

Lee, C.M., Ju, C.P., and Lin, J.H. Chern, Structureproperty relationship of cast Ti–Nb alloys, J. Oral Rehabilit., 2002, vol. 29, pp. 314–322.

Kollerov, M.Yu., Il’in, A.A., and Skvortsova, S.V., Effect of system and degree of alloying on the characteristics of shape memory effect of titanium alloys, Metally, 2001, no. 2, pp. 74–78.

Sheremetev, V.A., Prokoshkin, S.D., Brailovskii, V., Dubinskii, S.M., Korotitskii, A.V., Filonov, S.M., and Petrzhik, M.I., Investigation of the structure stability and superelastic behavior of thermomechanically treated Ti–Nb–Zr and Ti–Nb–Ta shape-memory alloys, Phys. Met. Metallogr., 2015, vol. 116, no. 4, pp. 413–422.

Konopatskii, A.S., Zhukova, Yu.S., Dubinskii, S.M., Korobkova, A.A., Filonov, M.P., and Prokoshkin, S.D., Microstructure of superplastic alloys based on Ti–Nb for medical purposes, Metallurgist, 2016, vol. 60, pp. 223–228.

Niinomi, M., Metallic biomaterials, Jap. Soc. Artif. Org., 2008, vol. 11, no. 3, pp. 105–110.

Sakaguchi, N., Niinomi, M., Akahori, T., Takeda, J., Toda, H., Relationships between tensile deformation behavior and microstructure in Ti–Nb–Ta–Zr system alloys, Mater. Sci. Eng. C, 2005, no. 25, pp. 363–369.

Conzalez, M., Pena, J., Manero, J.M., Arciniegas, M., and Gil, F.J., Design and characterization of new Ti–Nb–Hf alloys, J. Mater. Eng. Perform., 2009, vol. 18 (5–6), pp. 490–495.

Nitta, K., Watanabe, S., and Masahashi, N., Ni-free Ti–Nb–Sn shape memory alloys, in: Structural biomaterials for the 21 century, New Orleans: TMS, 2001, pp. 25–34.

Kawashima, A., Watanabe, S., Asami, K., and Hanada, S., XPS study of corrosion behavior of Ti–18Nb–4Sn shape memory alloy in a 0.05 mass % HCl solution, Mater. Trans., 2003, vol. 44, no. 7, pp. 1405–1411.

Kolobov, Yu.R., Valiev, R.Z., and Grabovetskaya, G.P., Grain-Boundary Diffusion and Properties of Nanostructured Materials, UK: Cambridge Int. Science, 2007.

Kolobov, Yu.R., Lipnitskii, A.G., Ivanov, M.B., and Golosov, E.V., Role of the diffusion-controlled processes in the formation of structure and properties of metallic materials, Compos. Nanostr., 2009, no. 2, pp. 5–24.

Andrievskii, R.A. and Glezer, A.M., Strength of nanostructures, Usp. Fiz. Nauk, 2009, vol. 179, no. 4, pp. 337–358.

Dubinskiy, S., Brailovski, V., Prokoshkin, S., Pushin V., Inaekyan, K., Sheremetyev, V., Petrzhik, M., and Filonov, M., Structure and properties of Ti–19.7Nb–5.8Ta shape memory alloy subjected to thermomechanical processing including aging, J. Mater. Eng. Perform., 2013, vol. 22, no. 9, pp. 2656–2664.

Hao, Y.L., Zhang, Z.B., Li, S.J., and Yang, R., Microstructure and mechanical behavior of a Ti–24Nb–4Zr–8Sn alloy processed by warm swaging and warm rolling, Acta Mater., 2012, vol. 60, pp. 2169–2177.

Václavová, K., Stráský, J., Veselý, J., Gatina, S., Polyakova, V., Semenova, I., and Janeček, M., Evolution of microstructure and microhardness in Ti–15Mo β-Ti alloy prepared by high pressure torsion, Mater. Sci. Forum., 2016, vol. 879, no. 9, pp. 2555–2560.

Gatina, S., Semenova, I., Leuthold, J., and Valiev, R., Nanostructuring and phase transformations in the β-Alloy Ti–15Mo during high-pressure torsion, Adv. Eng. Mater., 2015, vol. 17, no. 12, pp. 1742–1747.

Janeček, M., Čížek, J., Stráský, J., Václavová, K., Hruška, P., Polyakova, V., Gatina, S., and Semenova, I., Microstructure evolution in solution treated Ti15Mo alloy processed by high pressure torsion, Mater. Charact., 2014, vol. 98, pp. 233–240.

Yilmazer, H., Niinomi, M., Nakai, M., Cho, K., Hieda, J., Todaka, Y., and Miyazaki, T., Mechanical properties of a medical β-type titanium alloy with specific microstructural evolution through high-pressure torsion, Mater. Sci. Eng. C, 2013, vol. 33, pp. 2499–2507.

Golosova, O.A., Ivanov, M.B., Vershinina, T.N., and Kolobov, Yu.R., Structure and properties of low modulus titanium alloy Ti–26Nb–7Mo–12Zr, Mater. Sci. Technol., 2013, vol. 29, no. 2, pp. 204–209.

Betekhtin, V.I., Kolobov, Yu.R., Golosova, O.A., Kardashev, B.K., Kadomtsev, A.G., Narykova, M.V., Ivanov, M.B., and Vershinina, T.N., Elastoplastic properties of a low-modulus titanium-based β alloy, Technical Phys., 2013, vol. 58, no. 10, pp. 1432–1436.

Betekhtin, V.I., Kolobov, Yu.R., Golosova, O.A., Dvorak, J., Sklenicka, V., Kardashev, B.K., Kadomtsev, A.G., Narykova, M.V., and Ivanov, M.B., Elastic modulus, microplastic properties and durability of titanium alloys for biomedical applications, Rev. Adv. Mater. Sci., 2016, vol. 45, no. 1/2, pp. 42–51.

Kydryashov, S.I., Golosova, O.A., Kolobova, A.Yu., Kolobov, Yu.R., and Golosov, E.V., Comparative investigation of the features of the nanostructuring surface relief of α- and β-titanium alloys at pulsed femtosecond laser irradiation, Compoz. Nanostr., 2014, vol. 6, no. 3, pp. 2–11.

Kolobov, Yu.R., Golosov, E.V., Ratochka, I.V. Features of submicrocrystalline structure and its effect on mechanical properties of titanium alloys, Vopr. Materialoved., 2008, vol. 2, no. 54, pp. 43–50.

Author information

Authors and Affiliations

Corresponding author

Additional information

Original Russian Text © Yu.R. Kolobov, O.A. Golosova, S.S. Manokhin, 2018, published in Izvestiya Vysshikh Uchebnykh Zavedenii, Tsvetnaya Metallurgiya, 2018, No. 3, pp. 36–48.

About this article

Cite this article

Kolobov, Y.R., Golosova, O.A. & Manokhin, S.S. Regularities of Formation and Degradation of the Microstructure and Properties of New Ultrafine-Grained Low-Modulus Ti–Nb–Mo–Zr Alloys. Russ. J. Non-ferrous Metals 59, 393–402 (2018). https://doi.org/10.3103/S1067821218040090

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.3103/S1067821218040090