Abstract

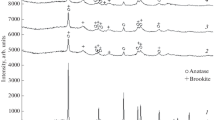

The structure and main physicochemical properties of dysprosium titanate powders prepared by mechanochemical synthesis from the low-temperature modification of titanium oxide and modification of dysprosium oxide are investigated applying X-ray phase analysis (XPA), scanning electron microscopy, Raman spectroscopy (Raman spectra), transmission electron microscopy, and chemical analysis. It is established based on XPA that the initial oxides completely transform into X-ray amorphous dysprosium titanate (Dy2TiO5) during the mechanochemical treatment of a mixture for 30–60 min. A microelectron diffraction pattern of Dy2TiO5 powders prepared by mechanosynthesis has a ring structure characteristic of the X-ray amorphous phase with a certain amount of inclusions of a crystalline phase. The dysprosium titanate powder fabricated by induction melting possesses the regular cubic crystalline lattice with a parameter of 3.4 Å.

Similar content being viewed by others

References

Sickafus, K.E., Grimes, R.W., Valdez, J.A., Cleave, A., Ming, Tang., Ishimaru, Manabu., Corish Siobhan, M., Stanek, Ch.R., and Uberuaga, B.P., Radiationinduced amorphization resistance and radiation tolerance in structurally related oxides, Nature Mater., 2007, no. 6, pp. 217–223.

Risovanny, V.D., Varlashova, E.E., Fridman, S.R., Ponomarenko, V.B., and Shcheglov, A.V., Comparative characteristics of absorbing cluster assemblies WWER-1000 and PWR, Atom. Energ., 1998, vol. 84, no. 6, pp. 508–513.

Belash, N.N., Kushtym, A.V., Tatarinov, V.R., and Chernov, I.A., Analysis of developments of constructions and materials for CPS ARabsorber elements with the increased efficiency, Yadern. Radiats. Tekhnol., 2007, vol. 7, nos. 3–4, pp. 18–28.

Risovanny, V.D., Zakharov, A.V., and Muraleva, E.M., New advanced absorbent materials for nuclear reactors on thermal neutrons, Vopr. Atom. Nauki Tekh. Ser: Fiz. Radiats. Povrezhd. Radiats. Materialoved., 2005, no. 3, pp. 87–93.

Risovanny, V.D., Zakharov, A.V., Muraleva, E.M., Kosenkov, V.M., and Latypov, R.N., Dysprozium hafnate as absorbing material for control rods, J. Nucl. Mater., 2006, vol. 355, pp. 163–170.

Fridman, S.R., Risovanny, V.D., Zakharov, A.V., and Toporova, V.G., Radiation stability of WWER-1000 CPS ARabsorber element with boron carbide, Vopr. Atom. Nauki Tekh. Ser: Fiz. Radiats. Povrezhd. Radiats. Materialoved., 2001, no. 2, pp. 84–90.

Perova, E.B., Spiridonov, L.N., and Komisarova, L.N., Phase equilibria in the HfO2–Dy2O3 system, Izv. Akad. Nauk SSSR. Neorg. Mater., 1982, vol. 8, no. 10, pp. 1878–1882.

Makhmudov, F.A., Shaimardanov, E.N., and Kabgov, Kh.B., Preparation and properties of nanostructured dysprosium oxides, Dokl. Akad. Nauk Resp. Tadzhikistan, 2013, vol. 56, no. 2, pp. 130–134.

Sinha, A. and Sharma, B.P., Development of dysprosium titanate based ceramics, J. Amer. Ceram. Soc., 2005, no. 2, pp. 238–241.

Khalameida, S.V., Some new approaches to mechanochemical synthesis of nanodispersed barium titanate, Nanosist., Nanomater., Nanotechnol. (Ukraina), 2009, vol. 7, no. 3, pp. 911–918.

Xue, J., Wang, J., and Wan, D., Nanosized barium titanate powder by mechanical activation, J. Amer. Ceram. Soc., 2000, vol. 83, no. 1, pp. 232–234.

Lyashenko, L.P., Shcherbakova, L.G., Kolbanev, I.V., Knerel’man, E.I., and Davydova, G.I., Mechanism of structure formation in samarium and holmium titanates prepared from mechanically activated oxides, Inorg. Mater., 2007, vol. 43, no. 1, pp. 46–54.

Szafraniak-Wiza, I., Hilczer, B., Talik, E., Pietraszko, A., and Malic, B., Ferroelectric perovskite nanopowders obtained by mechanochemical synthesis, Process. Appl. Ceram., 2010, vol. 4, no. 3, pp. 99–106.

Anokhin, A.S., Lyanguzov, N.V., Roshal’, S.B., Yuzyuk, Yu.I., and Wen Wang, Raman spectra of polycrystalline bismuth titanate nanotubes, Phys. Solid State, 2011, vol. 53, no. 9, pp. 1867–1871.

Shindo, D. and Oikawa, T., Analytical Electron Microscopy for Materials Science, Tokyo: Springer, 2002.

Brandon, D. and Kaplan, W.D., Microstructural Characterization of Materials, Wiley, 2002, 2nd ed.

Sidorova, O.V., Aleshina, L.A., and Kalinkin, A.M., Influence of mechanical activation of the structural state of strontium titanate, Fundam. Issled., 2014, no. 12–2, pp. 280–288. https://doi.org/www.fundamentalresearch.ru/ru/article/view?id=36218(accessed: May 17, 2016).

Author information

Authors and Affiliations

Corresponding author

Additional information

Original Russian Text © Zh.V. Eremeeva, V.S. Panov, L.V. Myakisheva, A.N. Lizunov, A.A. Nepapushev, D.A. Sidorenko, A.V. Pavlik, E.V. Apostolova, 2017, published in Izvestiya Vysshikh Uchebnykh Zavedenii, Poroshkovaya Metallurgiya i Funktsional’nye Pokrytiya, 2017, No. 1, pp. 11–19.

About this article

Cite this article

Eremeeva, Z.V., Panov, V.S., Myakisheva, L.V. et al. Structure and Properties of Dysprosium Titanate Powder Produced by the Mechanochemical Method. Russ. J. Non-ferrous Metals 59, 304–310 (2018). https://doi.org/10.3103/S1067821218030045

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.3103/S1067821218030045