Abstract

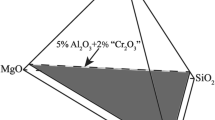

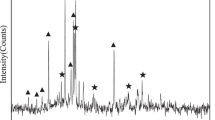

Balance calculations of multicomponent equilibrium compositions in the gas–liquid–solid system under oxidizing smelting of the copper-free copper-electrolyte slime, during which sulfur, selenium, and tellurium dioxides transfer into the gas phase, while compounds of lead, copper, antimony, iron, and aluminum are concentrated in the composition of the silicate slag, are performed with the help of the Outotec’s Chemical Reaction and Equilibrium Software HSC Chemistry program. It is established that, under optimal conditions of oxidizing smelting of the charge (100 kg) of the electrolyte slime (O2 ≈ 0.9 kg, SiO2 ≥ 6%, CaO ~ 3%, t = 1200°C), lead, antimony, and arsenic almost completely transfer into the silicate slag, while copper and silver (above 91%) transfer into the matte. Selenium is distributed between the gas phase (49.8%), matte (24.1%), and metallic phase (26.1%), while tellurium is distributed between sublimates (14.4%), silicate slag (8.4%), and matte (77.2%).

Similar content being viewed by others

References

Soshnikova, L.A. and Kupchenko, M.M., Pererabotka medeelektrolitnykh shlamov (Processing of Copper Electrolytic Slimes), Moscow: Metallurgiya, 1978.

Petrov, G.V., Oxidation features of silver selenide under sulfating, Kompl. Ispol’z. Miner. Syr’ya, 1987, no. 11, pp. 50–53.

Belen’kii, A.M., Boduen, A.Ya., and Petrov, G.V., Effect of oxidants in the liquid-phase sulfating of copper electrolytic slimes, Byul. Tsvetn. Metall., 2004, no. 9, pp. 17–20.

Kubasov, V.L., Nikol’ skaya, L.L., and Miroevskii, G.P., USSR Inventor’s Certificate No. 1678906, Byull. Izobret. no. 35, Sept. 1991.

Wood, P., Intec’s dendritic copper process poised for commercialization, Met. Powder Rep., 2001, vol. 56, no. 3, pp. 26–30.

Xie, F., Cai, T., and Ma, Y., Recovery of Cu and Fe from printed circuit board waste sludge by ultrasound: evaluation of industrial application, J. Clean. Prod., 2009, vol. 17, no. 16, pp. 1494–1498.

Amaral, F.A.D., Santos, V.S., and Bernardes, A.M., Metals recovery from galvanic sludge by sulfate roasting and thiosulfate leaching, Miner. Eng., 2014, vol. 60, pp. 1–7.

Chou, J.-D., Lin, C.-L., and Wey, M-Y., Effect of Cu species on leaching behavior of simulated copper sludge after thermal treatment: ESCA analysis, J. Hazard. Mater., 2010, vol. 179, nos. 1–3, pp. 1106–1110.

Hsiung, J.-S., Huang, Y.-C., and Li, K.-C., Study on the influence of additives in an industrial calcium fluoride and waterworks sludge co-melting system, J. Environ. Manage., 2007, vol. 84, no. 4, pp. 384–389.

Agrawal, A. and Sahu, K.K., Problems, prospects and current trends of copper recycling in India: An overview, Resour. Conservat. Recycl., 2010, vol. 54, no. 7, pp. 401–416.

Zhang, W. and Cheng, C.Y., Manganese metallurgy review. Pt. I: Leaching of ores/secondary materials and recovery of electrolytic/chemical manganese dioxide, Hydrometallurgy, 2007, vol. 89, nos. 3–4, pp. 137–159.

Torres, C.M., Taboada, M.E., and Graber, T.A., The effect of seawater based media on copper dissolution from low-grade copper ore, Miner. Eng., 2015, vol. 71, pp. 139–145.

Puts, G.J. and Crouse, P.L., The influence of inorganic materials on pyrolysis of polytetrafluoroethylene. Pt. 1: The sulfates and fluorides of Al, Zn, Cu, Ni, Co, Fe, and Mn, J. Fluorine Chem., 2014, vol. 168, pp. 260–267.

Sundman, B., Lu, X.-G., and Ohtani, H., The implementation of an algorithm to calculate thermodynamic equilibria for multi-component systems with non-ideal phases in a free software, Comput. Mater. Sci., 2015, vol. 101, pp. 127–137.

Littlejohn, P. and J. Vaughan, J., Selectivity of commercial and novel mixed functionality cation exchange resins in mildly acidic sulfate and mixed sulfate-chloride solution, Hydrometallurgy, 2012, vol. 121–124, pp. 90–99.

Mastyugin, S.A., Volkova, N.A., Naboichenko, S.S., and Lastochkina, M.A., Shlamy elektroliticheskogo rafinirovaniya medi i nikelya (Slimes from Electrolytic Refining of Copper and Nickel), Ekaterinburg: Ural Fed. Univ., 2013.

Author information

Authors and Affiliations

Corresponding author

Additional information

Original Russian Text © S.A. Krayuhin, G.I. Maltsev, K.L. Timofeev, S.S. Naboychenko, 2016, published in Izvestiya Vysshikh Uchebnykh Zavedenii. Tsvetnaya Metallurgiya, 2016, No. 2, pp. 12–17.

About this article

Cite this article

Krayuhin, S.A., Maltsev, G.I., Timofeev, K.L. et al. Thermodynamic prediction of melting of copper-electrolyte slime. Russ. J. Non-ferrous Metals 57, 175–179 (2016). https://doi.org/10.3103/S1067821216030093

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.3103/S1067821216030093