Abstract

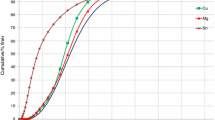

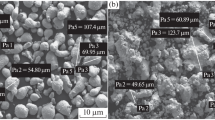

Shrinkage curves of alloys formed from the WC–8% Ni hard-alloy mixture activated by introducing 10% nanodimensional WC and charge without the additive in a temperature range of 800–1500°C are presented. The pore structure and microstructure of the samples at various stages of sintering are investigated. The peculiarity of densification of the modified alloy, which consists in the shift of the shrinkage curve into the lower temperature region, is revealed. This makes it possible to lower the temperature of the vacuumcompression sintering of alloy, form a finer grain structure, and attain high characteristics of hardness–wear resistance without worsening the strength characteristics. Physicomechanical properties and microstructure of compression-sintered samples made of VN8M activated alloy and standard VN8 alloy without additives are investigated.

Similar content being viewed by others

References

SANDVIK PN90. Nano-Series Cemented Carbide Grade for Printed Circuit Board Tooling, www.hardmaterials.sandvik.com.

You Wang, Zhaoyi Pan, Chengbiao Wang, et al., J. Mater. Sci. Technol., 2012, vol. 28, no. 3, pp. 205–213.

Borisenko, N.I. and Chichiro, E.A., Mater. Mezhdunar. nauch.-tekhn. konf. “Avtomobile-i-traktorostroenie v Rossii: Prioritety razvitiya i podgotovka kadrov” (Proc. Int. Sci.-Tech. Conf. Automobile-and-Tractor Industry), Moscow: Mos. Gos. Tekh. Univ. MAMI, 2010.

Mehrotra, P.K., Mizgalskiand, A K.P., Santhanam, T., Trudy 6-i Mezhdunarodnoi konferentsii po vol’framu, ogneuporam i tverdosplavam (Proc. 6th Int. Conf. on Tungsten, Refractory Materials, and Hard Alloys), Orlando, FL: 2006, pp. 7–8.

Plachenov, T.G. and Kolosentsev, S.D., Porometriya (Porometry), Leningrad: Khimiya, 1988.

Kurlov, A.S. and Rempel’, A.A., Neorg. Mater., 2009, vol. 45, no. 4, pp. 428–433.

Tret’yakov, V.I., Osnovy metallovedeniya i tekhnologii proizvodstva spechennykh tverdykh splavov (Foundations of Materials Science and Production Technology of Sintered Hard Alloys), Moscow: Metallurgiya, 1976.

Laptev, A.V., Poroshk. Metall., 2007, nos. 7/8, pp. 8–18.

Author information

Authors and Affiliations

Corresponding author

Additional information

Original Russian Text © D.V. Fedorov, O.V. Semenov, V.I. Rumyantsev, S.S. Ordan’yan, 2014, published in Izvestiya Vysshikh Uchebnykh Zavedenii. Poroshkovaya Metallurgiya i Funktsional’nye Pokrytiya, 2014, No. 3, pp. 26–30.

About this article

Cite this article

Fedorov, D.V., Semenov, O.V., Rumyantsev, V.I. et al. Compaction features during sintering VN8M alloy with additives of nanodimensional tungsten carbide. Russ. J. Non-ferrous Metals 57, 57–61 (2016). https://doi.org/10.3103/S1067821216010041

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.3103/S1067821216010041