Abstract

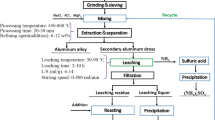

The main directions of resource-saving and environment-saving fabrication technologies of secondary aluminum alloys in modern industrial conditions are considered. The types of feedstocks and applied smelting aggregates are analyzed, and promising ways to further improve this production process are shown. It is revealed that the traditional processing method of secondary aluminum feedstock, which is widely used in practice, is thermal treatment in a medium of molten chloride salts. Salt-free technologies of processing aluminum dross, which are based on the separation of metal and oxides by the mechanical effect on them under conditions of high temperatures in the medium of the furnace atmosphere or collector metal, are proposed. Their advantages over the widespread salt technology are considered: materials applied to treat the melt are substantially less expensive than alkali metal chlorides; dump slags are environmentally pure; and the process has high productivity since it is performed in one metallurgical aggregate, which excludes the necessity of cleaning the walls and bottom part in it. The examples of implementing the salt-free processing technologies of aluminum feedstock under consideration under conditions of several Russian metallurgical enterprises are shown.

Similar content being viewed by others

References

Lainer, Yu.A., Reznichenko, V.A., Tuzhilin, A.S., et al., Tekhnol. Met., 2007, no. 6, pp. 2–11.

Keverhijan, V., J. Miner. Metal. Mater. Soc., 2002, vol. 54, no. 2, pp. 38–41.

Makarov, G.S., Tekhnol. Legk. Splav., 2004, no. 1, pp. 25–30.

How to develop aluminum recycling? Metallosnabzh. Sbyt, 2004, no. 4, pp. 64–66.

Golovnykh, N.V., Grigor’ev, V.G., Chernykh, A.A., et al., in Tr. Mezhdunarodnoi konferentsii “Strategiya razvitiya mineral’no-syr’evogo kompleksa v XXI veke” (Proc. Int. Conf. “Developmental Strategy of Mineral-Feedstock Complex in XXI Century), Moscow: Russ. Univ. People’s Friendship, 2004, pp. 170–172.

Lainer, Yu.A., Mil’kov, G.A., and Tuzhilin, A.S., in Tr. nauchno-tekhnicheskoi konferentsee “Problemy i perspektivy razvitiya metallurgii i mashinostroeniya s ispol’zovaniem zavershennykh fundamental’nykh issledovanii i NIOKR” (Proc. Sci.-and-Tech. Conf. “Problems and Prospects of the Development of Metallurgy and Machinery Using Finished Fundamental Studies and Research Design and Development Works”), Yekaterinburg: Ural Branch, Russ. Acad. Sci., 2011, vol. 2, pp. 581–587.

Kurchner, E., Erzmetall., 2002, vol. 55, no. 9, pp. 465–470.

Shustrov, A.Yu., Matsenko, Yu.A., and Nagibin, V.A., Tsvetn. Met., 2004, no. 1, pp. 70–73.

Larionov, G.V., Vtorichnyi alyuminii (Secondary Aluminum), Moscow: Metallurgiya, 1967.

Altodorfer, J., J. Miner. Metal. Mater. Soc., 2000, vol. 52, no. 11, pp. 19–25.

Khudyakov, I.F., Doroshkevich, A.P., Klyain, S.E., et al., Tekhnologiya vtorichnykh tsvetnykh metallov (Technology of Secondary Nonferrous Metals), Moscow: Metallurgiya, 1981.

Ireland, D.T., US Patent 6379418, 2002.

Barbin, N.K., Moiseev, G.K., Vatolin, N.A., et al., RF Patent 2244027, 2005.

Potanin, S.L., Mikhailov, V.I., Tumanov, V.N., et al., USSR Inventor’s Certificate No. 1199819, 1985.

Deev, V.B. and Selyanin, I.F., Khosen Ri, et al., Liteishchik Rossii, 2012, no. 10, pp. 14–17.

Deev, V.B., Degtyar, V.A., Kutsenko, A.I., et al., Steel Trans., 2007, vol. 37, no. 12, pp. 991–994.

Deev, V.B., Development of Scientific Foundations of Thermal and Electromagnetic Effects on Alloys and Development of Resource-Saving Fabrication Technologies of High-Quality Casts of Aluminum Alloys, Extended Abstract of Doctoral (Eng.) Dissertation, Komsomol’sk-na-Amure: Komsomol’sk-na-Amure State Tech. Univ., 2012.

Selyanin, I.F., Deev, V.B., Voitkov, A.P., and Bashmakova, N.V., Liteishchik Rossii, 2006, no. 2, pp. 18–20.

Kalenik, O.N., Nemenenok, B.M., Dovnar, G.V., and Tribushevskii, V.L., Metall. Mashinostr., 2004, no. 3, pp. 23–25.

Novichkov, S.B., Tsvetn. Met., 2004, no. 1, pp. 67–69.

Tribushevskii, V.L., Rimoshevskii, S.L., Ivanov, D.E., and Kalenik, O.N., Metall. Mashinostr., 2004, no. 3, p. 4.

Kon’ko, O.I., Kuris, Yu.V., and Gritsai, V.P., Vost.-Evrop. Zh. Peredovykh Tekhnol., 2011, no. 3/11 (51), pp. 11–12.

Huber, J., Elutrotechnik (Schweiz), 1988, no. 9, pp. 83–85.

Beckman, M. and Unger, T.W., in Proc. Tech. Ses. Annu. Meet. (San Diego: Calif.), Light Metals, 1992, pp. 1159–1162.

Galevskii, G.V., Kulagin, N.M., and Mintsis, M.Ya., Metallurgiya vtorichnogo alyuminiya (Metallurgy of Secondary Aluminum), Novosibirsk: Nauka, 1998.

Fedotov, V.M., Lebedev, V.N., and Kuznetsov, M.N., in Tekhnologiya. Ser. Resursosberegayushchie protsessy, oborudovanie, materialy (Technology. Ser. Resource-Saving Processes, Equipment, Materials), Moscow: All-Russia Inst. Interdepart. Inform, Res. Inst. Radio, 1994, part 1–2, pp. 39–41.

Vigier, P., Tirilly, L., and Julliard, J., Fr. Patent 2559786, 1985.

Kapur, E.P. and Medvedeva, L.N., USSR Inventor’s Certificate No. 753919, 1980.

Malinovskii, V.S., Malinovskii, V.D., Meshkov, M.A., and Yarnykh, L.V., Metall. Mashinostr., 2004, no. 4, pp. 2–7.

Shustrov, A.Yu., Matsenko, Yu.A., and Nagibin, V.A., Tsvetn. Met., 2004, no. 1, pp. 70–73.

Fedotov, V.M., Chervov, G.A., and Luchinin, N.M., RF Patent 2004607, 1993.

Fedotov, V.M. and Chervov, G.A., RF Patent 2002831, 1993.

Fedotov, M.V., Selyanin, I.F., and Fedotov, V.M., Liteishchik Rossii, 2007, no. 8, pp. 28–31.

Author information

Authors and Affiliations

Corresponding author

Additional information

Original Russian Text © I.F. Selyanin, V.B. Deev, A.V. Kukharenko, 2015, published in Izvestiya VUZ. Tsvetnaya Metallurgiya, 2015, No. 2, pp. 20–25.

About this article

Cite this article

Selyanin, I.F., Deev, V.B. & Kukharenko, A.V. Resource-saving and environment-saving production technologies of secondary aluminum alloys. Russ. J. Non-ferrous Metals 56, 272–276 (2015). https://doi.org/10.3103/S1067821215030189

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.3103/S1067821215030189