Abstract

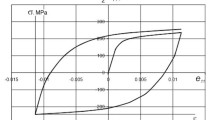

A way to take into account the influence of grain growth in the statement of the edge problem for the mechanics of a deformed solid as applied to the superplastic formation of microcrystalline and ultra-fine-grain materials is suggested. The concrete example of a numerical solution for the edge problem of creep theory in a medium of the ANSYS software complex according to the published experimental data is suggested. A satisfactory agreement between the results of the solution to the edge problem and the experimental data is obtained. This solution is analyzed, and certain features of the character of the stress-strained state in the deformation site are revealed. In particular, it is established that complex disproportionate loading occurs in the vicinity of the fastening contour. Under this loading, the stress trajectories in the Il’yushin space have a larger curvature, despite the fact that the curvature of the corresponding deformation trajectories in the deformation space is relatively small.

Similar content being viewed by others

References

Smirnov, O.M., Obrabotka metallov davleniem v sostoyanii sverkhplastichnosti (Pressure Treatment of Metals in the Superplasticity State), Moscow: Mashinostroenie, 1979.

Kaibyshev, O.A., Sverkhplastichnost’ promyshlennykh splavov (Superplasticity of Industrial Alloys), Moscow: Metallurgiya, 1984.

Masterov, V.A. and Berkovskii, V.S., Teoriya plasticheskoi deformatsii i obrabotki metallov davleniem (Theory of Plastic Deformation and Pressure Treatment of Metals), Moscow: Metallurgiya, 1989.

Valiev, R.Z. and Aleksandrov, I.V., Nanostrukturnye materialy, poluchennye metodom intensivnoi plasticheskoi deformatsii (Nanostructured Materials Obtained by the Method of Intense Plastic Deformation), Moscow: Logos, 2000.

Mulyukov, R.R., Ross. Nanotekhnol., 2007, vol. 2, nos. 7–8, p. 38.

Valiev, R.Z., Ross. Nanotekhnol., 2006, vol. 1, nos. 1–2, p. 208.

Kawasaki, M. and Langdon, T.G., J. Mater. Sci., 2007, vol. 42, p. 1782.

Valiev, R.Z., Islamgaliev, R.K., and Semenova, I.P., Mater. Sci. Eng., 2007, vol. A463, p. 2.

Mulyukov, R.R., Imayev, R.M., and Nazarov, A.A., J. Mater. Sci., 2008, vol. 43, p. 7257.

Kruglov, A.A. and Lutfullin, R.Ya., Probl. Mashinostr. Nadezhn. Mashin, 2009, no. 1, p. 69.

Lutfullin, R.Ya, Kruglov, A.A., Safiullin, R.V., et al., Mater. Sci. Eng., 2009, vol. A503, p. 52.

Padmanabhan, K.A., Vasin, R.A., and Enikeev, F.U., Superplastic Flow: Phenomenology and Mechanics, Berlin-Heidelberg: Springer, 2001.

Rabotnov, Yu.N., Polzuchest’ elementov konstruktsii (Creep of Construction Elements), Moscow: Nauka, 1966.

Vasin, R.A., Enikeev, F.U., Tokuda, M., and Safiullin, R.V., Int. J. Non-linear Mech., 2003, vol. 35, p. 799.

Kumar, V.S., Viswanathan, D., and Natarajan, S., J. Mater. Proc. Technol, 2006, vol. 173, p. 247.

O’Brien, M.J., Bremen, H.F., Furukawa, M., et al., Mater. Sci. Eng., 2007, vol. A456, p. 236.

Luckey, S.G., Friedman, P.A., and Weinmann, K.J., J. Mater. Proc. Technol., 2007, vol. 194, p. 30.

Yoon, J.H., Lee, H.S., Yi, Y.M., and Jang, Y.S., J. Mater. Proc. Technol., 2007, vol. 187–188, p. 463.

Giuliano, G. and Franchitti, S., Int. J. Machine Tools Manuf., 2007, vol. 47, p. 471.

Yoon, J.H., Lee, H.S., and Yi, Y.M., J. Mater. Proc. Technol., 2008, vol. 201, p. 68.

Giuliano, G. and Franchitti, S., Int. J. Machine Tools Manuf., 2008, vol. 48, p. 1519.

Hojjati, M.H., Zoorabadi, M., and Hosseinipour, S.J., J. Mater. Proc. Technol., 2008, vol. 205, p. 482.

Kruglov, A.A., Zagirov, T.M., Karimov, M.S., and Enikeev, F.U., Probl. Mashinostr. Avtomat., 2010, no. 2, p. 65.

Il’yushin, A.A., Plastichnost’ (Plasticity), Moscow: Gostekhizdat, 1948.

Author information

Authors and Affiliations

Corresponding author

Additional information

Original Russian Text © T.M. Zagirov, Yu.V. Zherebtsov, E.M. Kadirov, F. U. Enikeev, 2011, published in Izvestiya VUZ. Tsvetnaya Metallurgiya, 2011, No. 1, pp. 41–45.

About this article

Cite this article

Zagirov, T.M., Zherebtsov, Y.V., Kadirov, E.M. et al. Taking into account grain growth during the finite-element modeling of the superplastic formation of promising construction materials. Russ. J. Non-ferrous Metals 52, 39–43 (2011). https://doi.org/10.3103/S1067821211010263

Published:

Issue Date:

DOI: https://doi.org/10.3103/S1067821211010263