Abstract

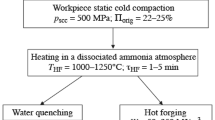

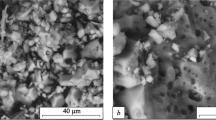

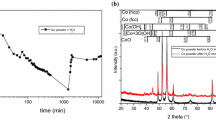

The purpose of the work was to experimentally investigate, simulate, and optimize the crushing methods of foundry alloys. The kinetics of crushing of the Fe-Cr-Al foundry alloy, which was performed in the drum and vibration mills, was investigated. The particle size was determined by two methods, namely, using the optical microscopy and by the specific surface of the powder. In the drum mill, the necessary dispersity of the foundry alloy (average particle size d p = 0.73 µ m) was achieved in the alcohol medium for 75 h. In the vibration mill, the optimal mode is crushing in the argon medium for 18 h (d p = 14 µ m). The vibration mill, compared with the drum one, decreases the preparation time of the foundry alloy by a factor of 1.5–2, which provides a decrease in the product cost.

Similar content being viewed by others

References

Popova, N.M., Katalizatory ochistki vykhlopnykh gazov avtotransporta (Vehicles Exhaust Treatment Catalysts), Alma-Ata: Nauka, 1987.

Zhegalin, O.I. and Lupachev, P.D., Snizheniye toksichnosti avtomobilnykh dvigateley (Vehicle Engines Toxicity Diminishing), M.: Transport, 1985.

Antsiferov, V.N., Artemov, A.A., and Porozova, S.E., Liteinoe Proizvod., 2001, No.1, S.11 [Foundry, 2001, No. 1, P. 11 (Engl. Transl.)].

Sheleg, V.K., Leonov, A.N., and Romashko, A.N., Poroshkovaya Metall. (Minsk), 2003, Vyp. 26, S. 82 [Powder Metallurgy (Minsk), 2003, Iss. 26, P. 82 (Engl. Transl.)].

Antsiferov, V.N., Koshcheyev, O.P., Feoktistova, N.S., et al., USSR Inventor’s Certificate no. 139567, 1980.

Khramtsov, V.D. and Lyudagovsky, A.V., Vestnik PGTU. Problemy Sovrem. Mater. Tekhnol. Sbornik nauchnykh trudov, 2002, Vyp. 8, S.114 [PGTU Bulletin. State-of-the-Art Materials and Technology Problems: Collected Articles, Perm: PGTU, 2002, Issue 8, P. 114 (Engl. Transl.)].

Libenson, G.A., Lopatin, V.Yu., and Komarnitsky, G.V., Protsessy poroshkovoy metallurgii. v 2 tomakh. T. 1. Proizvodstvo metallicheskikh poroshkov, uchebnik dlya vuzov (Process of Powder Metallurgy, 2 vols, vol. 1, Production of Metal Powder: High School Manual), Moscow: MISiS, 2001.

Author information

Authors and Affiliations

Corresponding author

Additional information

Original Russian Text © G.V. Bashkirtsev, 2009, published in Izvestiya VUZ. Poroshkovaya Metallurgiya i Funktsional’nye Pokrytiya, 2009, No. 2, pp. 50–53.

About this article

Cite this article

Bashkirtsev, G.V. Developing foundry alloy preparation technique for producing highly porous permeable cellular chromal. Russ. J. Non-ferrous Metals 50, 552–555 (2009). https://doi.org/10.3103/S1067821209050228

Published:

Issue Date:

DOI: https://doi.org/10.3103/S1067821209050228