Abstract

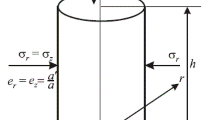

Based on the previously introduced mathematical model of the dynamic compaction of a powder material, the effect of the initial velocity of a tool and the ratio of its weight to the blank weight, which varies in a range of 102–104, on the shock velocity in the powder is considered using a titanium sponge as an example. According to the model, nonreversible volume changes in the material, which occur under the shock action, are considered on the basis of general conservation equations of mass, linear momentum, and energy, which are written for the discontinuity surface. It is shown that, in the investigated range of parameters of dynamic loading, the relationship between the velocities of the shock wave front and the tool can be approximated by a linear dependence. The pressure at the shock wave front and the shock pulse time are determined.

Similar content being viewed by others

References

Roman, O.V. and Gorobtsov, V.G., Aktual’nye problemy poroshkovoi metallurgii, Roman, O.V. and Arunachalam, V.S., Eds., Moscow: Metallurgiya, 1990.

Bogoyavlenskii, K.N., Kuznetsov, P.A., Mertens, K.K., et al., Vysokoskorostnye sposoby pressovaniya detalei iz poroshkovykh materialov (High-Speed Methods of Compaction of the Parts from Powdered Materials), Leningrad: Mashinostroenie, 1984.

Bragov, A.M., Rodionov, S.N., and Rusin, E.E., Pis’ma Zh. Tekh. Fiz., 2004, no. 21, p. 10.

Dmitriev, A.M. and Vorontsov, A.L., Tekhnologiya kovki i ob”emnoi shtampovki. Ch. 1. Ob”emnaya shtampovka vydavlivaniem: Ucheb. dlya vuzov (Technology of Forging and Bulk Stamping. Part 1. Bulk Stamping by Extrusion: Textbook for Colleges), Moscow: Vysshaya Shkola, 2002.

Krupin, A.V., Solov’ev, V.Ya., Popov, G.S., and Kr”stev, M.R., Obrabotka metallov vzryvom (Explosion Processing of Metals), Moscow: Metallurgiya, 1991.

Polyakov, A.P. and Mokrousova, M.S., Kuznech.-Shtamp. Proizv. Obrab. Met. Davl., 2004, no. 2, p. 20.

Dunin, S.Z. and Surkov, V.V., Zh. Prikl. Mekh. Tekh. Fiz., 1979, no. 5, p. 106.

Druyanov, B.A., Prikladnaya teoriya plastichnosti poristykh tel (Applied Theory of Plasticity of Porous Bodies), Moscow: Mashinostroenie, 1989.

Polyakov, A.P., Izv. Vyssh. Uchebn. Zaved., Tsvetn. Metall., 2005, no. 4, p. 35.

Kolachev, B.A., Livanov, V.A., and Bukhanova, A.A., Mekhanicheskie svoistva titana i ego splavov (Mechanical Properties of Titanium and Its Alloys), Moscow: Metallurgiya, 1974.

Polyakov, A.P. and Zalazinskaya, E.A., Izv. Vyssh. Uchebn. Zaved., Tsvetn. Metall., 2003, no. 1, p. 30.

Author information

Authors and Affiliations

Corresponding author

Additional information

Original Russian Text © A.P. Polyakov, 2009, published in Izvestiya VUZ. Tsvetnaya Metallurgiya, 2009, No. 1, pp. 30–34.

About this article

Cite this article

Polyakov, A.P. The effect of parameters of dynamic loading on the propagation character of shock waves in a powder. Russ. J. Non-ferrous Metals 50, 33–38 (2009). https://doi.org/10.3103/S106782120901009X

Published:

Issue Date:

DOI: https://doi.org/10.3103/S106782120901009X