Abstract

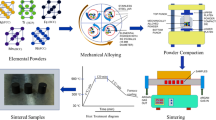

Features of the influence of Al2O3, ZrO2, WC, and Si3N4 nanoparticles on the process of obtainment, mechanical, and tribological properties of the 74%Fe-15%Co-9%Cu-1%Sn alloy obtained by powder metallurgy methods are investigated. Mixing nanoparticles with alloy powder was performed in a centrifugal planetary mill. It is shown that the nanoparticles uniformly distributed over the charge complicate the processes of compaction during cold pressing and sintering. The alloy (dispersion strengthened by nanoparticles), which was obtained by the technology of hot pressing, is characterized by high mechanical and tribological properties. Wear resistance increases by a factor of four, hardness is increased by 10–16 HRB, and the bending breaking point is increased by 54%.

Similar content being viewed by others

References

Anosov, Yu.L., Antonova, T.N., and Bondarev, E.K., Sinteticheskie sverkhtverdye materialy (Synthetic Superhard Materials), Novikov, N.V., Ed., Kiev: Naukova Dumka, 1986, vol. 2.

Zhadanovskii, B.V., Tekhnologiya almaznoi mekhanicheskoi obrabotki stroitel’nykh materialov i konstruktsii (Technology of Diamond Mechanical Treatment of Building Materials and Constructions), Moscow: Stroiizdat, 2004.

Varenkov, A.N., Kostikov, V.I., and Nozhkina, A.V., Fizikokhimiya vzaimodeistviya almazov s metallami, splavami i soedineniyami (Physical Chemistry of Interaction of Diamonds with Metals, Alloys, and Compounds), Moscow: MISiS, 1986.

Ylikerälä, J. and Gasik, M., Metal Powder Rep., 2004, vol. 59, no. 9, p. 36.

Spriano, S., Chen, Q., Settineri, L., and Bugliosi, S., Wear, 2005, vol. 259, nos. 7–12, p. 1190.

Tillmann, W., Gathen, M., Vogli, E., and Kronholz, C., Metal Powder Rep., 2007, vol. 62, no. 7, p. 43.

Nitkiewicz, Z. and Świerzy, M., J. Mater. Process. Tekhnol., 2006, vol. 175, nos. 1–3, p. 306.

Zaitsev, A.A., Kurbatkina, V.V., and Levashov, E.A., Izv. Vyssh. Uchebn. Zaved., Tsvetn. Metall., 2008, no. 5, p. 53.

Levahsov, E.A., Andreev, V.A., and Kurbatkina, V.V., RF Patent 2 286 241, 2007.

Levahsov, E.A., Andreev, V.A., and Kurbatkina, V.V., RF Patent 2 286 242, 2007.

Levahsov, E.A., Andreev, V.A., and Kurbatkina, V.V., RF Patent 2 286 243, 2007.

Levashov, E.A., Andreev, V.A., and Kurbatikina, V.V., Appl. 2007/055 616 (WO), Binder for the Fabrication of Diamond Tools, 2007.

Heinike, G., Tribochemistry, Berlin: Academie-Verlag, 1984.

Boldyrev, V.V. and Tkasova, A.K., J. Mater. Synth. Proces., 2000, vol. 8, nos. 3–4, p. 121.

Yegorychev, K.N., Kurbatkina, V.V., and Levashov, E.A., Izv. Vyssh. Uchebn. Zaved., Tsvetn. Metall., 1996, no. 6, p. 49.

Avvakumov, V.G., Mekhanicheskie metody aktivirovaniya khimicheskikh protsessov (Mechanical Methods of Activation of Chemical Processes), Novosibirsk: Nauka, 1986.

Kurbatkina, V.V., Levashov, E.A., and Rogachev, A.S., Combustion in Heterogeneous Systems: Fundamentals and Application for Materials Synthesis, Mukasyan, A.S. and Martirosyan, K.S., Eds., Kerala: Transword Research Network, 2007, p. 131.

Borisova, A.L., Sovmestimost’ tugoplavkikh soedinenii s metallami i grafitom: Spravochnik (Compatibility of Refractory Compounds with Metals and Graphite: Handbook), Kiev: Naukova Dumka, 1985.

Author information

Authors and Affiliations

Corresponding author

Additional information

Original Russian Text © A.A. Zaitsev, V.V. Kurbatkina, E.A. Levashov, 2008, published in Izvestiya VUZ. Poroshkovaya Metallurgiya i Funktsional’nye Pokrytiya, 2008, No. 5, pp. 35–41.

About this article

Cite this article

Zaitsev, A.A., Kurbatkina, V.V. & Levashov, E.A. Features of the influence of nanodispersed additions on the process of and properties of the Fe-Co-Cu-Sn sintered alloy. Russ. J. Non-ferrous Metals 49, 414–419 (2008). https://doi.org/10.3103/S1067821208050180

Published:

Issue Date:

DOI: https://doi.org/10.3103/S1067821208050180