Abstract

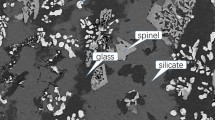

With the HSC Chemistry ver. 4.1 program software, the possibility of obtaining oxidic and spinel phases during the oxidation of chalcopyrite is evaluated and the equilibrium compositions of the oxidized product in the temperature range from 1000 to 1800 K are calculated. For qualitative and quantitative estimation of the phases presenting in the oxidized product, an experiment with chalcopyrite mineral (fraction <100 μm) in a laboratory furnace simulating the flash smelting process at the temperature 973 K has been carried out. The phases obtained after the oxidation of the sulfide particles are identified with the help of x-ray phase analysis. For qualitative and quantitative estimation, determination of the phases is undertaken: electron probe microanalysis (EPMA) and Mössbauer spectroscopy along with the applied chemical analysis. It is established that the contents of copper and iron oxides and spinel phases in the oxidized product are close to the equilibrium composition corresponding to the average combustion temperature of the sulfide particles.

Similar content being viewed by others

References

Makipirtti S., The First International Flash Smelting Congress, Finland, 1972, pp. 221–293.

Kemori, N., Denholm, W.T., Kurokawa, H., Metal. Trans. B, 1989, vol. 20B, pp. 327–336.

Jorgensen, F.R.A., Proc. Australas. Inst. Min. Metall., 1983, no. 288, pp. 37–46.

Hagni, R.D., Vierrether, C.B., and Sohn, H.Y., Metal. Trans. B, 1988, vol. 19B, pp. 719–729.

Kang, J.S. and Pyun, S.I., Trans. Inst. Min. Metall. C, 1988, vol. 97, pp. C198–C206.

Fagerlung, K., Jalkanen, H., Nurmi, P., and Taskinen, P., Abstracts of Papers, EPD Congress, The Minerals, Metals, and Materials Society, 1997, pp. 635–647.

Peuraniemi, E.J. and Jokilaakso, A., Abstracts of Papers, EPD Congress, The Minerals, Metals, and Materials Society, 2000, pp. 173–187.

Stefanova, V., Genevski, K., and Stefanov, B., Can. Met. Quart., 2004, vol. 43, no. 1, pp. 75–88.

Stefanov, B., Krumova, D., and Stefanova, V., Abstracts of Papers, Proc. 9th Int. Metallurgy and Materials Congress, Istanbul, pp. 11–15.

Ahokainen, T., Jokilaakso, A., Vaarno, J., and Jarvi, J., Abstracts of Papers, Int. Conference on CFD in Mineral & Metal Processing and Power Generation, CSIRO, Australia: 1997, pp. 213–221.

Ahokainen, T. and Joiklaakso, A., Can. Met. Quart., 1998, vol. 37, nos. 3–4, pp. 275–283.

Adams, J.B.R., Davis, K.A., Heap, M.P., and Sarofim, A.F., Abstracts of Papers, 4th Int. Conf. Copper 99-Cobre 99, Phoenix, AZ, 1999.

Vaarno, J., Järvy, J., Ahokainen, T., Laurila, T., and Taskinen, P., Abstracts of Papers, 3rd Int. Conf. on CFD in the Minerals and Process Industries, CSIRO, Melbourne: 2003, pp. 147–154.

Solnordal, B.S., Jorgensen, F.R.A., Koh, P.T.L., and Hunt, A., Abstracts of Papers, 3rd Int. Conf. on CFD in the Minerals and Process Industries, CSIRO, Melbourne: 2003, pp. 161–166.

Laurila, T., Oikari, R., Joutsenova, T., Mikkola, P., Ranki-Kilpinen, T., Taskinen, P., and Hernberg, R., Met. Mater. Trans. B, 2005, vol. 36B, pp. 201–208.

Roine, A., Outokumpu HSC Chemistry for Windows, Version 4.0, Outokumpu Research Oy, Finland: 1999.

Kobakhidze, V.V., Talis, L.D., Kazhdan, A.A., Indenbaum, G.V., and Boinykh, N.M., Tsvetn. Met., 1991, no. 6, pp. 19–22.

Razumov, I.M., Psevdoozhizhenie i pnevmotransport sypuchikh materialov (Fluidization and Pneumatic Transport of Loose Materials), Moscow: Khimiya, 1972.

Munro, M.D.H. and Themelis, N.J., Abstracts of Papers, Proc. Copper 91-Cobre 91 Int. Symp., 1991, no. 4, pp. 475–494.

Jokilaakso, A.T., Suominen, R.O., Taskinen, P.A., and Lilius, K.R., Trans. Inst. Min. Met., 1991, pp. C79–C90.

Parra, R., Fan, Y.H., and Wilkomirsky, I., Abstracts of Papers, 6th Int. Conf. on Molten Slags, Fluxes and Salts, Stockholm-Helsinki: 2000.

Espinel, J.A., M.Sc. Thesis, Universidad de Concepcion, Escuela de Graduados, Marzo: 1985.

Kuzmann, E., Nagy, S., and Verses, A., UIPAC Tech. Rep., Pure Appl. Chem., 2003, vol. 75, no. 6, pp. 851–858.

Parfenov, V.V. and Nazipov, R.A., Inorg. Mater. (English Translation), 2002, vol. 38, no. 1, pp. 78–82.

Plocek, J., Hutlova, A., Nižňansky, D., Buršik, J., Rehspringer, J.L. and Mička, Z., Abstracts of Papers, Conf. Nano’02, Brno: 2002.

Author information

Authors and Affiliations

Additional information

This article was submitted by the authors in English.

About this article

Cite this article

Stefanova, V., Trifonov, Y. Phase composition of spinel melts obtained during flash smelting of the mineral chalcopyrite. Russ. J. Non-ferrous Metals 49, 148–155 (2008). https://doi.org/10.3103/S1067821208030048

Published:

Issue Date:

DOI: https://doi.org/10.3103/S1067821208030048