Abstract

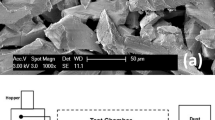

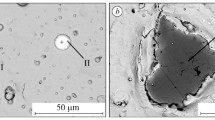

Nitrides of high-entropy alloys TiZrHfVNb produced using a vacuum-arc cathode evaporation have been studied using scanning electron and atomic force microscopies, energy dispersive, Rutherford ions backscattering, and X-ray diffraction analyses, microhardness measurements, and tribological tests. It has been found that the deposition parameters affect the structure, surface morphology, distribution of elements, mechanical and tribological properties of the coatings under study.

Similar content being viewed by others

References

Pogrebnjak, A.D. and Kravchenko, Yu.A., Modification of Mechanical Properties of TiN/Al2O3 and TiN/Cr/Al2O3Coatings Using Low-Energy High-Current Electron Beams, J. Superhard Mater., 2013, vol. 35, no. 2, pp. 105–110.

Musil, J., Hard Nanocomposite Coatings: Thermal Stability, Oxidation Resistance and Toughness, Surf. and Coat. Tech., 2012, vol. 207, pp. 50–65.

Pogrebnjak, A.D., Shpak, A.P., Azarenkov, N.A. and Beresnev, V.M., Structure and properties of Hard and Superhard Nanocomposite Coatings, UPhN, 2009, vol. 179, no. 1, pp. 35–63.

Pogrebnyak, A.D., Ponomarev, A.G., Kolesnikov, et al., Effect of Mass Transfer and Segregation on the Formation of Superhard Nanostructured Ti-Hf-N(Fe) Coatings, Techn. Phys. Lett., 2012, vol. 38, no. 7, pp. 623–626.

Pogrebnjak, A.D., Beresnev, V.M., Demianenko, A.A., Baidak, V.S., Komarov, F.F., Kaverin, M.V., Makhmudov, N.A., and Kolesnikov, D.A., Adhesive Strength, Supermicrohardness, and the Phase and Elemental Compositions of Nanostructured Coatings Based on Ti-Hf-Si-N, Phys. of the Solid State, 2012, vol. 54, no. 9, pp. 1882–1890.

Pogrebnjak, A.D., Shpak, A.P., Beresnev, V.M., et al., Effect of Thermal Annealing in Vacuum and Air on Nanograin Sizes in Hard and Superhard Coatings Zr-Ti-Si-N, J. Nanosci. and Nanotechn., 2012, vol. 12, no. 12, pp. 9213–9219.

Borisov, D.P., Moshkov, D.Yu., Ovchinnikov, S.V., Oskomov, K.V., Pinzhin, Yu.P., Savostikov, V.M., Tyumentsev, A.N., and Korotaev, A.D., Nanocomposite and Nanostructural Superhard Coatings of the Ti-Si-B-N System, Isvestiya Vuzov, Fizika, 2007, vol. 50, no. 10, pp. 13–23.

Pogrebnjak, A.D., Sobol, O.V., Beresnev, V.M., et al., Phase Composition, Thermal Stability, Physical and Mechanical Properties of Superhard on Base Zr-Ti-Si-N Nanocomposite Coatings, Nanostructured Materials and Nanotechnology, IV: Ceramic Eng. Sci. Proc., 2010, vol. 31, no. 7, pp. 127–138.

Veprek, S. and Veprek-Heijman, M.G.J., Limits to the Preparation of Superhard Nanocomposites: Impurities, Deposition, and Annealing Temperature, Thin Solid Films, 2012, vol. 522, pp. 274–282.

Yeh, J.-W., Chen, Y.-L., Lin, S.-J, and Chen, S.-K., High Entropy Alloys—A New Era of Exploitation, Mater. Sci. Forum, 2007, vol. 560, pp. 1–9.

Lai, C.-H., Tsai, M.-H., Lin, S.-J., and Yeh, J.-W., Influence of Substrate Temperature on Structure and Mechanical, Properties of Multi-Element (AlCrTaTiZr)N Coatings, Surf. Coat. Technol., 2007, vol. 201, pp. 6993–6998.

Huang, P.K. and Yeh, J.W., Effects of Nitrogen Content on Structure and Mechanical Properties of Multi-Element (AlCrNbSiTiV)N Coating, ibid., 2009, vol. 203, pp. 1891–1896.

Chang, Sh.-Y. and Chen, D.-Sh., 10-nm-Thick Quinary (AlCrTaTiZr)N Film as Effective Diffusion Barrier for Cu Interconnects at 900°C, Appl. Phys. Lett., 2009, vol. 94, art. 231909.

Liang, S.-Ch., Chang, Z.-Ch., Tsai, D.-Ch., Lin, Y.-Ch., Sung, H.-Sh., Deng, M.-J., and Shieu, F.-Sh., Effects of Substrate Temperature on the Structure and Mechanical Properties of (TiVCrZrHf)N Coatings, Appl. Surf. Sci., 2011, vol. 257, pp. 7709–7713.

Chang, Z.-Ch., Liang, Sh.-Ch., and Han, Sh., Effect of Microstructure on the Nanomechanical Properties of TiVCrZrAl Nitride Films Deposited by Magnetron Sputtering, Nuclear Instruments and Methods in Physics Research B, 2011, vol. 269, pp. 1973–1976.

Krause-Reihberg, R., Pogrebnjak, A.D., Borisyuk, V.N., Kaverin, M.V., Ponomarev, A.G., Belokur, M.A., Oishi, K., Takeda, I., Beresnev, V.M., and Sobol’, O.V., Analysis of Local Regions Near Interfaces in Nanostructural Multicomponent Coatings (Ti-Zr-Hf-V-Nb)N, Produced by the Cathodic-Arc-Vapor Deposition from the Arc of the Evaporating Cathode, Physics of Metals and Metallography, 2013, vol. 114, no. 8, pp. 672–680.

Mishra, Aj.K., Samal, S., and Biswas, Kr., Solidification Behavior of Ti-Cu-Fe-Co-Ni High Entropy Alloys, Transactions of the Indian Institute of Metals, 2012, vol. 65, issue 6, pp. 725–730.

Tsai, Ch.-W., Lai, S.-W., Cheng, K.-H., et al., Strong Amorphization of High-Entropy AlBCrSiTi Nitride Film, Thin Solid Films, 2012, vol. 520, issue 7, pp. 2613–2618.

Firstov, S.A., Gorban’, V.F., Krapivka, N.A., and Pechkovskii, E.P., Hardening and Mechanical Properties of Cast High-Entropy Alloys, Composity i Nanostruktury, 2011, no. 2, pp. 5–20.

Braic, V., Balaceanu, M., Braic, M.A., Vladescu, A., et al., Characterization of Multi-Principal-Element (TiZrNbHfTa)N and (TiZrNbHfTa)C Coatings for Biomedical Applications, J. Mechanical Behavior of Biomedical Materials, 2012, vol. 10, pp. 197–205.

Khomenko, A.V. and Prodanov, N.V., Molecular Dynamics Simulations of Ultrathin Water Film Confined between Flat Diamond Plates, Condensed Matter., 2008, vol. 11, no. 4(56), pp. 615–626.

Khomenko, A.V., Noise Influence on Solid-Liquid Transition of Ultrathin Lubricant Film, Phys. Lett. A, 2004, vol. 329, no. 1-2, pp. 140–147.

Kotunowicz, T.N., Zukowski, P.V., Fedotova, V.V., Saad, A.M., Larkin, A.V., and Fedotov, A.K., The Features of Real Part of Admittance in the Nanocomposites (Fe45Co45Zr10)(Al2O3)100−x Manufactured by the Ion-Beam Sputtering Technique with Ar Ions, Acta Physica Polonica A, 2011, vol. 120, no. 1, pp. 35–38.

Larkin, A.V., Fedotov, A.K., Fedotova, J.A., Kotunowicz, T.N., and Zukowski, P.V., Temperature and Frequency Dependences of Impedance Real Part in the FeCoZr-Doped PZT Nanogranular Composites, Mater. Science-Poland, 2012, vol. 30, issue 2, pp. 75–81.

Author information

Authors and Affiliations

Additional information

Original Russian Text © A.D. Pogrebnjak, I.V. Yakushchenko, G. Abadias, P. Chartier, O.V. Bondar, V.M. Beresnev, Y. Takeda, O.V. Sobol’, K. Oyoshi, A.A. Andreyev, B.A. Mukushev, 2013, published in Sverkhtverdye Materialy, 2013, Vol. 35, No. 6, pp. 36–51.

About this article

Cite this article

Pogrebnjak, A.D., Yakushchenko, I.V., Abadias, G. et al. The effect of the deposition parameters of nitrides of high-entropy alloys (TiZrHfVNb)N on their structure, composition, mechanical and tribological properties. J. Superhard Mater. 35, 356–368 (2013). https://doi.org/10.3103/S106345761306004X

Received:

Published:

Issue Date:

DOI: https://doi.org/10.3103/S106345761306004X