Abstract

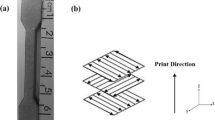

An analysis is performed of the structure and phases of porous samples of the 316L austenitic steel obtained via laser 3D printing. Residual δ-ferrite is found (along with austenite) in the sample via transmission electron microscopy. High density of dislocations is observed in the sample as well. ESBD analysis revealed the textureless state of the sample.

Similar content being viewed by others

REFERENCES

Barannikova, S.A., Nikonova, A.M., and Kolosov, S.V., Vestn. Perm. Nats. Issled. Politekh. Univ., Mekh., 2021, no. 1, p. 22.

Shrinivas, V., Varma, S.K., and Murr, L.E., Metall. Mater. Trans. A, 1995, vol. 26, p. 661.

Tucho, W.M. and Lysne, V.H., Austbø, H., et al., J. Alloys Compd., 2018, vol. 740, p. 910.

Solomon, N. and Solomon, I., Rev. Met., 2010, vol. 46, no. 2, p. 121.

Meszaros, I. and Prohaszka, J., J. Mater. Process. Technol., 2005, vol. 161, p. 162.

Nalepka, K., Skocze, B., Ciepielowska, M., et al., Materials, 2021, vol. 14, p. 127.

Gradzka-Dahlke, M. and Waliszewski, J., Defect Diffus. Forum, 2009, vol. 283, p. 285.

Vock, S., Klöden, B., Kirchner, A., et al., Prog. Addit. Manuf., 2019, vol. 4, p. 383.

Bartolomeu, F., Buciumeanu, M., Pinto, E., et al., Addit. Manuf., 2017, vol. 16, p. 81.

Bajaj, P., Hariharan, A., Kini, A., et al., Mater. Sci. Eng., A, 2020, vol. 772, p. 138633.

Sun, Z., Tan, X., Tor, S.B., Yeong, W.Y., Mater. Des., 2016, vol. 104, p. 197.

Krakhmalev, P., Fredriksson, G., Svensson, K., et al., Metals, 2018, vol. 8, p. 643.

Tucho, W.M., Lysne, V.H., Austbo, H., et al., J. Alloys Compd., 2018, vol. 740, p. 910.

Lo, K.H., Mater. Sci. Eng., R, 2009, vol. 65, p. 39.

Saluja, R. and Moeed, K., Int. J. Eng. Sci. Technol., 2012, vol. 4, no. 5, p. 2206.

Fofanov, D. and Riedner, S., Proc. 2011 Software Shaping Workshop Conference and Exhibition, Maastricht, 2011, p. 1.

Andreaua, O., Koutiri, I., Patrice Peyre, P., et al., J. Mater. Proccess. Technol., 2019, vol. 264, p. 21.

ACKNOWLEDGMENTS

The structural investigations were performed at the Electron Microscopy Center of the Institute of Metal Physics’ Testing Center of Nanotechnology and Advanced Materials.

Funding

This work was supported by the Russian Science Foundation, project no. 22-29-01514.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

The authors declare that they have no conflicts of interest.

Additional information

Translated by A. Shishulin

About this article

Cite this article

Kazantseva, N.V., Vinogradova, N.I., Koemets, Y.N. et al. Electron Microscope Study of Phase Transformations in 316L Austenitic Steel Produced via Laser 3D Printing. Bull. Russ. Acad. Sci. Phys. 87, 1438–1442 (2023). https://doi.org/10.3103/S1062873823703458

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.3103/S1062873823703458