Abstract

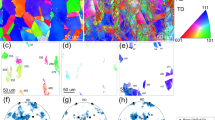

Investigation of the evolution of the parameters of crystallographic texture, microstructure, and mechanical properties of single-phase copper-based alloys with 10 and 30 wt % concentrations of Zn subjected to flat rolling in the coarse-grained state and preformed ultrafine-grained state are performed. A decrease in the stacking fault energy and an increase in the degree of reduction during flat rolling increases the values of the orientation distribution functions corresponding to twin orientations, decreases the grain size and coherent scattering regions, and increases the dislocation density and the twinning probability. These changes have a positive effect on the strength properties of the studied alloys.

Similar content being viewed by others

REFERENCES

Carter, C.B. and Ray, I.L.F., Philos. Mag., 1977, vol. 35, no. 1, p. 189.

Hirsch, P., Philos. Mag., 1962, vol. 7, p. 1349.

Qu, S., An, X.H., Yang, H.J., et al., Acta Mater., 2009, vol. 57, no. 5, p. 1586.

Zhang, P., An, X.H., Zhang, Z.J., et al., Scr. Mater., 2012, vol. 67, p. 871.

Gallagher, P.C.J., Metall. Trans., 1970, vol. 1, no. 9, p. 2429.

Valiev, R.Z., Islamgaliev, R.K., and Alexandrov, I.V., Prog. Mater. Sci., 2000, vol. 45, p. 103.

Wang, Z., Wang, Y., Liao, X., et al., Scr. Mater., 2009, vol. 60, no. 1, p. 52.

Zhao, Y., Horita, Z., Langdon, T., et al., Mater. Sci. Eng., A, 2008, vol. 474, no. 1.

Zhang, Z., Duan, Q., An, X. et al., Mater. Sci. Eng., A, 2011, vol. 528, no. 12, p. 4259.

An, X., Lin, Q., Wu, S., et al., Scr. Mater., 2011, vol. 64, no. 3, p. 249.

Ungar, T., Balogh, L., Zhu, Y., et al., Mater. Sci. Eng., A, 2007, vol. 444, no. 1.

Bahmanpour, H., Youssef, K., Horky, J., et al., Acta Mater., 2012, vol. 60, no. 8, p. 3340.

Roy, B., Kumar, N., Gopalakrishnan Nambissan, P., et al., AIP Adv., 2014, vol. 4, no. 6, 067101.

Konkova, T., Mironova, S., Korznikov, A., et al., Mater. Charact., 2015, vol. 101, p. 173.

Jamaati, R. and Toroghinejad, M., Mater. Sci. Eng., A, 2014, vol. 598, p. 263.

Kallend, J.S. and Davies, G.J., Texture, 1972, vol. 1, p. 51.

Gu, C.F., Toth, L.S., Zhang, Y., and Hoffman, M., Scr. Mater., 2014, vol. 92, p. 51.

Lapeire, L., Sidor, J., Verleysen, P., et al., Acta Mater., 2015, vol. 95, p. 224.

Suwas, S. and Ray, R., Crystallographic Texture of Materials, London: Springer, 2014.

Yan, H., Zhao, X., Jia, N., et al., J. Mater. Sci. Technol., 2014, vol. 30, no. 4, p. 408.

Valiev, R.Z. and Aleksandrov, I.V., Ob”emnye nanostrukturnye metallicheskie materialy: poluchenie, struktura i svoistva (Bulk Nanostructured Metallic Materials: Preparation, Structure, and Properties), Moscow: Akademkniga, 2007.

Lutterotti, L., Matthies, S., and Wenk, H.R., Proc. 12th Int. Conf. Textured Materials, 1999, vol. 1, p. 1599.

Warren, B.E., Prog. Metal. Phys., 1959, vol. 8, p. 147.

Williamson, G.K. and Smallman, R.E., Philos. Mag., 1956, vol. 1, p. 34

https://labosoft.com.

An, X.H., Wu, S.D., Wang, Z.G., and Zhang, Z.F., Prog. Mater. Sci., 2019, vol. 101, p. 1.

Christian, J.W. and Mahajan, S., Prog. Mater. Sci., 1995, vol. 39, p. 1.

El-Danaf, E., Kalidindi, S.R., Doherty, R.D., et al., Acta Mater., 2000, vol. 48, p. 2665.

Funding

This work was supported by the Russian Foundation for Basic Research, project no. 19-33-90109; and by the RF Ministry of Science and Higher Education, project no. 0838-2020-0006 “Fundamental Study of New Principles for Creating Promising Electromechanical Energy Converters with Characteristics above the World Level, Increased Efficiency, and Minimum Specific Indicators, Using Highly Efficient Electrotechnical Materials.”

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

The authors declare they have no conflicts of interest.

Additional information

Translated by E. Boltukhina

About this article

Cite this article

Zaynullina, L.I., Alexandrov, I.V. Evolution of Crystallographic Texture, Microstructure, and Mechanical Properties during Flat Rolling of Alloys of the Cu–Zn System with Different Grain Sizes. Bull. Russ. Acad. Sci. Phys. 86, 1301–1308 (2022). https://doi.org/10.3103/S1062873822110351

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.3103/S1062873822110351