Abstract

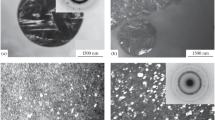

The structure of amorphous Ti50Ni25Cu25 alloy is investigated upon megaplastic deformation in a Bridgman chamber at room temperature. The dependences of average and local fractions of the crystalline phase along a sample’s radius on deformation are obtained. Radial distribution functions that allow calculation of the interatomic distances and coordinate numbers in several coordinate shells of investigated sample are found. It is concluded that the amorphous state in a Ti50Ni25Cu25 system fabricated by melt quenching is virtually the same as the one that arises through deformation-driven amorphization at room temperature in a Bridgman chamber.

Similar content being viewed by others

References

Nosova, G.I. Shalimova, A.V., et al., Kristallografiya, 2009, vol. 54, no. 6, pp. 1111–11183.

Glezer, A.M., Sundeev, R.V., and Shalimova, A.V., Dokl. Akad. Nauk, 2011, vol. 440, no. 1, pp. 39–42.

Prokoshkin, S.D., Khmelevskaya, I.Yu., et al., Acta Mater., 2005, vol. 53, pp. 2703–2714.

Pushin, V.G., Kuranova, N.N., et al., Fiz. Met. Metalloved., 2012, vol. 113, no. 3, pp. 286–298.

Zhilyaev, A.P. and Langdon, T.G., Prog. Mater. Sci., 2008, vol. 53, pp. 893–979.

Moroz, E.M., Usp. Khim., 2011, vol. 80, no. 4, pp. 315–332.

Veligzhanin, A.A., Zubavichus, Ya.V., et al., Vestn. Tomsk. Gos. Univ., 2013, vol. 18, no. 3, pp. 1709–1711.

Shelekhov, E.V. and Sviridova, T.A., Metalloved. Term. Obrab. Met., 2000, no. 8, pp. 16–22.

Visser, J.W., J. Appl. Crystallogr., 1975, vol. 8, pp. 1–7.

Blank, V.D. and Estrin, E.I., Fazovye prevrashcheniya v tverdykh telakh pri vysokom davlenii (Phase Transitions in Solids under High Pressures), Moscow: Fizmatlit, 2011.

De Lima, J.C., Poffo, C.M., et al., Phys. B: Condens. Matter, 2013, vol. 424, pp. 60–68.

Glezer, A.M., Permyakova, I.E., et al., Mekhanicheskoe povedenie amorfnykh splavov (Mechanical Behavior of Amorphous Alloys), Novokuznetsk: Siberian State Industrial Univ., 2006.

Author information

Authors and Affiliations

Corresponding author

Additional information

Original Russian Text © A.V. Shalimova, A.A. Veligzhanin, R.V. Sundeev, Ja.V. Zubavichus, A.M. Glezer, A.A. Chernyshov, 2014, published in Izvestiya Rossiiskoi Akademii Nauk. Seriya Fizicheskaya, 2014, Vol. 78, No. 11, pp. 1506–1512.

About this article

Cite this article

Shalimova, A.V., Veligzhanin, A.A., Sundeev, R.V. et al. Comparative analysis of the amorphous phases obtained in Ti50Ni25Cu25 alloy using different approaches. Bull. Russ. Acad. Sci. Phys. 78, 1232–1237 (2014). https://doi.org/10.3103/S1062873814110240

Published:

Issue Date:

DOI: https://doi.org/10.3103/S1062873814110240