Abstract

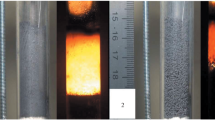

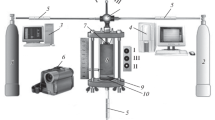

For the first time, a comparative study of the macrokinetic combustion parameters for granular and powder Ti + C and (Ti + C) + 20% Ni mixtures with variation in Ti particle sizes from 31 to 142 µm was carried out. It was found that the combustion velocity of (Ti + C) + 20% Ni powder mixture is 2–3 times higher than that of Ti + C mixture, in spite of the lower combustion temperature. The data obtained contradict theoretical concepts about the dependence of the combustion velocity on the maximum temperature, which leads to a formal negative value of the activation energy of combustion. In the convective–conductive model of combustion, these unusual results are explained by the strong effect of impurity gas release on the combustion velocity. For Ti + C and (Ti + C) + 20% Ni compositions, the conditions for heating particles of powder mixtures in the combustion wave warm-up zone were experimentally confirmed. The values of the reaction front velocity inside the granules were calculated using values of combustion velocities of samples with granules 0.6–1.7 mm in diameter for different sizes of Ti particles. They turned out to be several times higher than combustion velocities of powder mixtures with the same composition. The ratio of the values of the combustion velocity of the substance of the granules to the burning front velocity in the powder mixture can serve as a quantitative measure of the effect of the release of impurity gases on the burning velocity of powder mixtures. For both mixture compositions, the same power function ~d–0.9 approximates dependences of the combustion velocity inside the granules on the Ti particle size, which indicates the leading role of the Ti + C reaction in the propagation of the combustion wave.

Similar content being viewed by others

REFERENCES

Rogachev, A.S. and Mukasyan, A.S., Combustion for Material Synthesis, New York: CRC Press Taylor & Francis Group, 2015.

Han, J.-C., Zhang, X.-H., and Wood, J.V., In-situ combustion synthesis and densification of TiC–xNi cermets, Mater. Sci. Eng. A, 2000, vol. 280, pp. 328–333. https://doi.org/10.1016/S0921-5093(99)00606-1

Huang, L., Wang, H.Y., Qiu, F., and Jiang, Q.C., Synthesis of dense ceramic particulate reinforced composites from Ni–Ti–C, Ni–Ti–B, Ni–Ti–B4C, and Ni–Ti–C–B systems via the SHS reaction, arc melting and suction casting, Mater. Sci. Eng. A, 2006, vol. 422, pp. 309–315. https://doi.org/10.1016/j.msea.2006.02.019

Li, Y., Bai, P., Wang, Y., Hu, J., and Guo, Z., Effect of TiC content on Ni/TiC composites by direct laser fabrication, Mater. Des., 2009, vol. 30, pp. 1409–1412. https://doi.org/10.1016/j.matdes.2008.06.046

Liu, G., Li, J., and Chen, K., Combustion synthesis of refractory and hard materials: A review, Int. J. Refr. Met. Hard Mater., 2013, vol. 39, pp. 90–102. https://doi.org/10.1016/j.ijrmhm.2012.09.002

André, B., Levin, E., Jansson, U., and Wiklund, U., Friction and contact resistance of nanocomposite Ti–Ni–C coatings, Wear, 2011, vol. 270, pp. 555–566. https://doi.org/10.1016/j.wear.2010.12.006

Kiryukhantsev-Korneev, P., Sytchenko, A., Sheveyko, A., and Vorotilo, S., Structure and properties of protective coatings deposited by pulsed cathodic arc evaporation in Ar, N2, and C2H4 environments using the TiC–NiCr–Eu2O3 cathode, Coatings, 2019, vol. 9, pp. 230–243. https://doi.org/10.3390/coatings9040230

Sahoo, C.K. and Masanta, M., Microstructure and mechanical properties of TiC–Ni coating on AISI304 steel produced by TIG cladding process, J. Mater. Process. Technol., 2017, vol. 240, pp. 126–137. https://doi.org/10.1016/j.jmatprotec.2016.09.018

Merzhanov, A.G., Solid flames: discovery, concepts, and horizon of cognition, Combust. Sci. Technol., 1994, vol. 98, pp. 307–336. https://doi.org/10.1080/00102209408935417

Vershinnikov, V.I. and Filonenko, A.K., Pressure dependence of rate of gas-free combustion, Combust. Explos. Shock Waves, 1978, vol. 14, pp. 588–592.

Dunmead, S.D., Readey, D.W., and Semler, C.E., Kinetics of combustion synthesis in the Ti–C and Ti–C–Ni systems, J. Amer. Ceram. Soc.,1989, vol. 72, pp. 2318–2324. https://doi.org/10.1111/j.1151-2916.1989.tb06083.x

Varma, A., Rogachev, A.S., Mukasyan, A.S., and Hwang, S., Combustion synthesis of advanced materials: principles and applications, Adv. Chem. Eng., 1998, vol. 24, pp. 79–226. https://doi.org/10.1016/S0065-2377(08)60093-9

Rogachev, A.S., Microkinetics of gasless combustion: old problems and new approaches, Int. J. Self-Propag. High-Temp. Synth., 1997, vol. 6, pp. 215–240.

Aldushin, A.P., Martem’yanova, T.M., Merzhanov, A.G., Khaikin, B.I., and Shkadinskii, K.G., Propagation of the front of an exothermic reaction in condensed mixtures with the interaction of the components through a layer of high-melting product, Combust. Explos. Shock Waves, 1972, vol. 8, vol. 159–167.

Azatyan, T.S., Mal’tsev, V.M., Merzhanov, A.G., and Seleznev, V.A., Spectral-optical investigation of the mechanism of the combustion of mixtures of titanium and carbon, Combust. Explos. Shock Waves, 1977, vol. 13, pp. 156–158. https://doi.org/10.1007/BF00754993

Kachelmayer, C.L., Varma, A., Rogachev, A.S., and Sytschev, A.E., Influence of reaction mixture porosity on the effective kinetics of combustion synthesis, Ind. Eng. Chem. Res.,1988, vol. 37, pp. 2246–2249. https://doi.org/10.1021/ie9704915

Shcherbakov, V.A., Sytschev, A.E., and Shteinberg, A.S., Outgassing macrokinetcs in SPS, Combust. Explos. Shock Waves, 1986, vol. 22, pp. 437–443. https://doi.org/10.1007/BF00862888

Merzhanov, A.G., Rogachev, A.S., Umarov, L.M., and Kir’yakov, N.V., Experimental study of the gas phase formed in the processes of self-propagating high-temperature synthesis, Combust. Explos. Shock Waves, 1997, vol. 33, pp. 439–447. https://doi.org/10.1007/BF02671837

Mukas'yan, A.S., Shugaev, V.A., and Kir’yakov, N.V., Effect of gaseous fluid phases on combustion of metals in nitrogen, Combust. Explos. Shock Waves, 1993, vol. 29, pp. 7–11. https://doi.org/10.1007/BF00755319

Kamynina, O.K., Rogachev, A.S., and Umarov, L.M., Deformation dynamics of a reactive medium during gasless combustion, Combust. Explos. Shock Waves, 2003, vol. 39, pp. 548–551. https://doi.org/10.1023/A:1026161818701

Seplyarskii, B.S. and Vadchenko, S.G., Role of convective heat transfer in gasless combustion by the example of combustion of the Ti–C system, Dokl. Phys. Chem., 2004, vol. 398, pp. 203–207. https://doi.org/10.1023/B:DOPC.0000041487.87644.26

Vadchenko, S.G., Effect of thermal treatment in vacuum on ignition of titanium compacts in hydrogen, Int. J. Self-Propag. High-Temp. Synth., 2010, vol. 19, pp. 206–208. https://doi.org/10.3103/S1061386210030064

Seplyarskii, B.S., The nature of the anomalous dependence of the velocity of combustion of “gasless” systems on the sample diameter, Dokl. Phys. Chem., 2004, vol. 396, pp. 130–133. https://doi.org/10.1023/B:DOPC.0000033505.34075.0a

Rubtsov, N.M., Seplyarskii, B.S., and Alymov, M.I., Ignition and Wave Processes in Combustion of Solids, Cham, Switzerland: Springer International Publishing AG, 2017.

Seplyarskii, B.S. and Kochetkov, R.A., Granulation as a tool for stabilization of SHS reactions, Int. J. Self-Propag. High-Temp. Synth., 2017, vol. 26, pp. 134–136. https://doi.org/10.3103/S106138621702011X

Amosov, A.P., Makarenko, A.G., Samboruk, A.R., Seplyarskii, B.S., Samboruk, A.A., Gerasimov, I.O., Orlov, A.V., and Yatsenko, V.V., Effect of batch pelletizing on a course of SHS reactions: An overview, Int. J. Self-Propag. High-Temp. Synth., 2010, vol. 19, pp. 70–77. https://doi.org/10.3103/S1061386210010127

Seplyarskii, B.S. and Kochetkov, R.A., A study of the characteristics of the combustion of Ti + xC (x > 0.5) powder and granular compositions in a gas coflow, Russ. J. Phys. Chem. B, 2017, vol. 11, pp. 798–807. https://doi.org/10.1134/S1990793117050116

Seplyarsky, B.S., Kochetkov, R.A., Lisina, T.G., Abzalov, N.I., and Alymov, M.I., Phase composition and structure of titanium carbide/nickel binder synthesis products, Inorg. Mater., 2019, vol. 55, pp. 1104–1110. https://doi.org/10.1134/S0020168519110116

Vorotilo, S., Kiryukhantsev-Korneev, Ph.V., Seplyarskii, B.S., Kochetkov, R.A., Abzalov, N.I., Kovalev, I.D., Lisina, T.G., and Zaitsev, A.A., (Ti,Cr)C-based cermets with varied NiCr binder content via elemental SHS for perspective cutting tools, Crystals, 2020, vol. 10, pp. 412–428. https://doi.org/10.3390/cryst10050412

Seplyarskii, B.S., Kochetkov, R.A., Lisina, T.G., and Abzalov, N.I., Effect of a Ti + C granule size on combustion in a nitrogen flow, Combust. Explos. Shock Waves, 2021, vol. 57, pp. 60–66. https://doi.org/10.1134/S001050822101007X

Seplyarskii, B.S., Kochetkov, R.A., Lisina, T.G., Rubtsov, N.M., and Abzalov, N.I., Macrokinetic analysis of the combustion patterns in the transition from powder to granular mixtures by the example of compositions 5Ti + 3Si and Ti + C, Combust. Flame, 2022, vol. 236, p. 111811. https://doi.org/10.1016/j.combustflame.2021.111811

Zenin, A.A., Merzhanov, A.G., and Nersisyan, G.A., Thermal wave structure in SHS processes, Combust. Explos. Shock Waves, 1981, vol. 17, pp. 63–71. https://doi.org/10.1007/BF00772787

Slezak, T., Zmywaczyk, J., and Koniorczyk, P., Thermal diffusivity investigations of the Titanium Grade 1 in wide temperature range, AIP Conf. Proc., 2019, vol. 2170, p. 020019. https://doi.org/10.1063/1.5132738

Korol’chenko, I.A., Kazakov, A.V., and Kukhtin, A.S., Experimental determination of thermal diffusivity of materials, Пожаровзрывоопасность веществ и материалов, 2004, vol. 13, pp. 36–38.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

The authors declare that they have no conflicts of interest.

About this article

Cite this article

Seplyarskii, B.S., Kochetkov, R.A., Lisina, T.G. et al. Explanation of Increase in Combustion Velocity of Ti + C Powder Mixture upon Dilution with Nickel Using Convective–Conductive Combustion Model. Int. J Self-Propag. High-Temp. Synth. 31, 195–207 (2022). https://doi.org/10.3103/S1061386222040100

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.3103/S1061386222040100