Abstract

During the synthesis of MAX phases using combustion synthesis (or Self-Propagating High-temperature Synthesis), the main drawback is the presence of binary phases, and especially the simple MX carbide, when X = C. Our experiments were designed in order to check whether the cooling rate of the sample immediately after synthesis might play a key role for obtaining samples with low-level carbide contents. In the best conditions, a TiC content of about 2% only has been observed. A systematic study on the direct effect of the cooling rate on the final composition has then been conducted, and confirms that high cooling rates allow the synthesis of high-purity MAX phases in the Ti-Al-C system.

Similar content being viewed by others

References

Jeitschko, W., Nowotny, H., and Benesovsky, F., Die H-Phasen Ti2TlC, Ti2PbC, Nb2InC, Nb2SnC und Ta2GaC, Monatsh. Chem., 1964, vol. 95, p. 1004.

Barsoum, M.W., Brodkin, D., and El-Raghy, T., Layered Machinable Ceramics for High-Temperature Applications, Scr. Mater., 1997, vol. 36, no. 5, pp. 535–541.

Barsoum, M.W. and El-Raghy, T., Synthesis and Characterization of a Remarkable Ceramic: Ti3SiC2, J. Am. Ceram. Soc., 1996, vol. 79, no. 7, pp. 1953–1956.

Barsoum, M.W. and El-Raghy, T., Room Temperature Ductile Carbides, Metall. Mater. Trans., Ser. A, 1999, vol. 30, pp. 363–369.

Pampuch, R., Lis, J., Stobierski, L., and Tymkiewicz, M., Solid Combustion Synthesis of Ti3SiC2, J. Eur. Ceram. Soc., 1989, vol. 5, p. 283.

Pampuch, R., Lis, J., et al., Ti3SiC2-Based Materials Produced by Self-Propagating High-Temperature Synthesis and Ceramic Processing, J. Mater. Synth. Process., 1993, vol. 1, no. 1, pp. 93–98.

Lis, J., Miyamoto, Y., Pampuch, R., et al., Ti3SiC2-Based Materials Prepared by HIP-SHS Technique, Mater. Lett., 1995, vol. 22, no. 3, pp. 163–168.

Morgiel, J., Lis, J., and Pampuch, R., Microstructure of Ti3SiC2-Based Ceramics, Mater. Lett., 1986, vol. 27, pp. 85–89.

Lis, J., Pampuch, R., Rudnik, T., et al., Reaction Sintering Phenomena of Self-Propagating High-Temperature Synthesis-Derived Ceramic Powders in the Ti-Si-C System, Solid State Ionics, 1997, vols. 101–103, no. 1, pp. 59–64.

Feng, A. Orling, T., and Munir, Z.A., Field-Activated Pressure-Assisted Combustion Synthesis of Polycrystalline Ti3SiC2, J. Mater. Res., 1999, vol. 14, pp. 925–939.

Khoptiar, Y. and Gotman, I., Synthesis of Dense Ti3SiC2-Based Ceramics by Thermal Explosion under Pressure, J. Eur. Ceram. Soc., 2003, vol. 23, pp. 47–53.

Barsoum, M.W., El-Raghy, T., and Ogbuji, L., Oxidation of Ti3SiC2 in Air, J. Electrochem. Soc., 1997, vol. 144, no. 7, pp. 2508–2516.

Barsoum, M.W., El-Raghy, T., and Radovic, M., Ti3SiC2: A Layered Machinable Ductile Carbide, Interceram, 2000, vol. 49, pp. 226–233.

Barsoum, M.W., Yoo, H.I., Polushina, I.K., Rud, V.Yu., Rud, Yu.V., and El-Raghy, T., Electrical Conductivity, Thermopower, and Hall Effect of Ti3AlC2, Ti4AlN3, and Ti3SiC2, Phys. Rev., Ser. B, 2000, vol. 62, no. 15, pp. 10195–10198.

Chlubny, L. and Lis, J., Intermetallics as Precursors in SHS Synthesis of the Ti3AlC2, in Abstr. IX Int. Symp. on SHS, Dijon, France, 2007.

Racault, C., Langlais, F., and Naslain, R., Solid-State Synthesis and Characterization of the Ternary Phase Ti3SiC2, J. Mater. Sci., 1994, vol. 29, no. 13, pp. 3384–3392.

Gauthier, V., Cochepin, B., Dubois, S., and Vrel, D., Self-Propagating High-Temperature Synthesis of Ti3SiC2: Study of the Reaction Mechanism by Time-Resolved X-Ray Diffraction and Infrared Thermography, J. Am. Ceram. Soc., 2006, vol. 89, no. 9, pp. 2899–2907.

Rogachev, A.S., Gachon, J.-C., Grigoryan, H.E., Vrel, D., Schuster, J.C., and Sachkova, N.V., Phase Evolution in the Ti-Al-B and Ti-Al-C systems during Combustion Synthesis: Time Resolved Study by Synchrotron Radiation Diffraction Analysis, J. Mater. Sci., 2005, vol. 40, nos. 9–10, pp. 2689–2691.

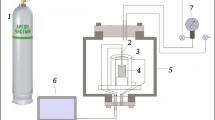

Vrel, D., Girodon-Boulandet, N., Paris, S., Mazué, J.-F., Couqueberg, E., Gailhanou, M., Thiaudiére, D., Gaffet, E., and Bernard, F., A New Experimental Setup for the Time Resolved X-ray Diffraction Study of Self-Propagating High-Temperature Synthesis, Rev. Sci. Instrum., 2003, vol. 73, no. 2, pp. 422–428.

Bernard, F., Paris, S., Vrel, D., Gailhanou, M., Gachon, J.-C., and Gaffet, E., Time-Resolved XRD Experiments Adapted to SHS Reactions: Past and Future, Int. J. SHS, 2002, vol. 12, no. 2, pp. 181–190.

Cochepin, B., Heian, E.M., Karnatak, N., Vrel, D., and Dubois, S., TiC nucleation/Growth Processes during CHS Reactions, Powder Technol., 2005, vol. 157, pp.92–99.

Author information

Authors and Affiliations

Corresponding author

About this article

Cite this article

Hendaoui, A., Andasmas, M., Amara, A. et al. SHS of high-purity MAX compounds in the Ti-Al-C system. Int. J Self-Propag. High-Temp. Synth. 17, 129–135 (2008). https://doi.org/10.3103/S1061386208020088

Received:

Published:

Issue Date:

DOI: https://doi.org/10.3103/S1061386208020088