Abstract

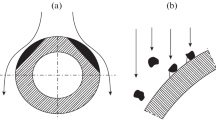

During operation of the International Thermonuclear Experimental Reactor (ITER), its removable blanket modules undergo significant shock loads in the process of plasma disruption, which lead to the displacement of parts with a gas-thermal insulating coating on the mount points of the protective panels of the vacuum chamber. A high friction coefficient \(f~\) ≥ 0.28 at maximum shear resistance provokes peeling, fracturing, and chipping of insulating coatings. Methods of reducing the friction coefficient of supporting surfaces coated with an electrical insulation coating (Al2O3, MgAl2O4) and mount points of the ITER blanket modules experiencing significant shear stresses are considered. The tribotechnical tests of electrical insulating coatings paired with the proposed modified zirconium alloy plates with an antifriction layer in the range of sliding speeds \({v}\) = 10–5−10–2 m/s, loads \(N\) = 100−600 N according to the pin-on-disk scheme at temperatures \(T\) = 20°C, T = 250°C showed a change in the friction coefficient in the range \(f\) = 0.08−0.23 and high wear resistance of ceramic coatings. The use of innovative intermediate plates with a modified layer (ZrO2−C) in blanket modules could be an alternative to low pressure plasma spraying of an antifriction MoS2 finish layer on electrical insulation coatings.

Similar content being viewed by others

REFERENCES

IO ITER, Insulating coatings for the blanket system components, ITER_D_25QF6 v. 1.4, 2013.

IO ITER, ITER Vacuum Vessel Load Specification, ITER_D_2F52JY v. 3.3, 2013.

Danilov, I.V., Leshukov, A.Yu., Razmerov, A.V., Sviridenko, M.N., Strebkov, Yu.S., Mazul’, I.V., Ger-vash, A.A., and Labusov, A.N., The supporting structure of the first wall of the ITER blanket module, Vopr. At. Nauki Tekh., Ser. Termoyad. Sintez, 2013, vol. 36, no. 1, p. 17.

Dragunov, Yu.G., Leshukov, A.Yu., Strebkov, Yu.S., Kirillov, S.Yu., Makarov, S.V., Trofimovich, P.D., et al., Design development, manufacture and experimental justification of the health of the components of the ITER blanket system, Vopr. At. Nauki Tekh., Ser. Termoyad. Sintez, 2016, vol. 39, no. 4, p. 13.

Poddubnyi, I., Kolganov, V., Elkin, V., Khomiakov, S., Danilov, I., Strebkov, Yu., et al., Analysis and experimental justification of electrical connector for ITER blanket module, Fusion Eng. Des., 2017, vol. 124, p. 516.

Khomiakov, S., Poddubnyi, I., Kolganov, V., Zhmakin, A., Parshutin, E., Danilov, I., et al., ITER blanket module connectors. Design, analysis and testing for procurement arrangement, Fusion Eng. Des., 2016, vols. 109–111, Part C, p. 261.

Suvorova, A.A., Danilov, I.V., Kalinin, G.M., and Korostelev, A.B., Heat treatment effects on the microstructure and properties of Cu–Cr–Zr alloy used for the ITER blanket components, Nucl. Mater. Energy, 2018, vol. 15, p. 80.

Zaitsev, A.N., Strebkov, Yu.S., Leshukov, A.Yu., Ivanov, V.M., Kuksenova, L.I., Sachek, B.Ya., Mezrin, A.M., and Aleksandrova, Yu.P., Assessment of critical level of shear stresses in tribocouples of Al2O3 and metal details of ITER blanket modules, J. Mach. Manuf. Reliab., 2016, vol. 45, no. 6, p. 522.

Baldaev, L.Kh., Renovatsiya i uprochnenie detalei mashin metodami gazotermicheskogo napyleniya (Renovation and Hardening of Machine Parts Using Thermal Spraying Methods), Moscow: KKhT, 2004.

ASTM G99 Standart Test Method for Wear Testing with Pin-on-Disk Apparatus, West Conshohocken, PA: ASTM Int., 1999.

Materialy dlya uzlov sukhogo treniya, rabotayushchikh v vakuum: Spravochnik (Materials for Dry Friction Units Working in a Vacuum, The Handbook), Tseev, N.A., Kozelkin, V.V., and Gurov, A.A., Eds., Moscow: Mashinostroenie, 1991.

Isaev, V.G. and Kostylev, A.G., Dusting in dynamic vacuum—the further way of improvement of quality of coverings, Inform.-Tekhnol. Vestn., 2016, no. 3 (09), p. 114.

Young, E.J., Mateeva, E., Moore, J.J., Mishra, B., and Loch, M., Low pressure plasma spray coatings, Thin Solid Films, 2000, vol. 377, p. 788.

Ouyang, J.H. and Sasaki, S., Tribological characteristics of low-pressure plasma-sprayed Al2O3 coating from room temperature to 800°C, Tribol. Int., 2005, vol. 38, p. 49.

Zaitsev, A.N., Aleksandrova, Yu.P., and Yagopol’skii, A.G., A comparative analysis of physical and mechanical properties of gas-thermal radiation-resistant electrical insulating coatings depending on the application method, Izv. Vyssh. Uchebn. Zaved., Ser. Mashinostr., 2018, no. 6, p. 12.

Gazotermicheskie pokrytiya iz poroshkovykh materialov: Spravochnik (Thermal Coatings of Powder Materials: A Guide), Borisov, Yu.S., Kharlamov, Yu.A., Sidorenko, S.L., and Ardatovskaya, E.N., Eds., Kiev: Naukova Dumka, 1987.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

The authors declare they have no conflict of interest.

Additional information

Translated by M. Chubarova

About this article

Cite this article

Zaitsev, A.N., Aleksandrova, Y.P. Reduction of Shear Stresses in Friction Units with an Electrical Insulation Coating of the ITER Blanket Modules. J. Mach. Manuf. Reliab. 49, 763–769 (2020). https://doi.org/10.3103/S1052618820090137

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.3103/S1052618820090137