Abstract

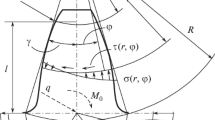

The results of the simulation of the deformation mode in the root of the teeth of cylindrical involute gears under the action of a concentrated force are given. It is the first step in determining the bending strength of involute teeth in the case that at least some of them (those in a pinion or in a gear) have a longitudinal surface modification providing for a contact that is a point one from the theoretical point of view and local from the practical point of view. The investigations have been performed using the finite-element model developed in an ANSYS environment. Taking into account the effective (equivalent) stresses responsible for damaging the material of the teeth, the volume factor of the shape of the tooth has been reduced to a form that makes it possible to use the bending durability limits specified for ordinary (unmodified) teeth of involute gears with a theoretically linear contact, which enter the working stresses for estimating the bending resistance.

Similar content being viewed by others

References

GOST (State Standard) no. 21354-87: Involute Cylindrical Tooth Gears. Strength Calculation, Moscow: Izd. standartov, 1988.

Chasovnikov, L.D., Peredachi zatsepleniem (zubchatye i chervyachnye) (Catching Gears (Tooth and Worm)), Moscow: Mashinostroenie, 1969.

MR (Methodological Recommendations) no. 221-86: Novikov’s Tooth Gears with HB ≥ 350 Hardness of Teeth Surface. Strength Calculation, Moscow: VNIIMASh, 1987.

Korotkin, V.I., Onishkov, N.P., and Kharitonov, Yu.D., Zubchatye peredachi Novikova. Dostizheniya i razvitie (Novikov’s Tooth Gears. Achievements and Development), Moscow: Mashinostroenie-1, 2007.

Ustinenko, V.L., Napryazhennoe sostoyanie zub’ev tsilindricheskikh pryamozubnykh koles (Teeth Stress Condition of Cylindrical Straight-Toothed Wheels), Moscow: Mashinostroenie, 1972.

Litvin, F.L., Teoriya zubchatykh zatseplenii (Gear Theory), Moscow: Nauka, 1968.

Timoshenko, S.P., Soprotivlenie materialov (Strength of Materials), Moscow: Nauka, 1965, vol. 2.

Yakovlev, A.S., On Detecting the Bending Stresses in Cylindrical Gear Teeth by Means of Finite Boundary Element Method, Mashinoved., 1982, no. 2, p. 89–94.

Koval’skii, B.S., Raschet detalei na mestnoe szhatie (Details Calculation against Local Pressure), Kharkov: KhVKIU, 1967.

Yakovlev, A.S., The Way to Estimate the Stress State of Teeth Material for Novikov’s Gears, Izv. Vyssh. Uchebn. Zaved. Mashinostroen., 1985, no. 6, pp. 13–16.

Additional information

Original Russian Text © V.I. Korotkin, E.M. Kolosova, D.Yu. Sukhov, 2010, published in Problemy Mashinostroeniya i Nadezhnosti Mashin, 2010, No. 6, pp. 63–69.

About this article

Cite this article

Korotkin, V.I., Kolosova, E.M. & Sukhov, D.Y. Calculation of the bending stresses of involute teeth with longitudinal surface modification. J. Mach. Manuf. Reliab. 39, 562–567 (2010). https://doi.org/10.3103/S1052618810060099

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.3103/S1052618810060099