Abstract

A serious environmental impact of Russian blast furnaces is the generation of copious dust on account of the low strength of the sinter and pellets employed. Their strength may be increased if red mud from alumina production is introduced in the initial batch. A problem here is that the red mud lowers the iron content in the blast-furnace batch. However, this effect may be compensated by reducing the content of fines in the batch, according to research on the chemical composition of Russian blast-furnace batch. The minimum iron content in the red mud at which such compensation is feasible is established.

Similar content being viewed by others

References

Utkov, V.A. and Leont’ev, L.I., Increasing of the strength of agglomerates and pellets by bauxite red mud, Stal’, 2005, no. 9, pp. 2–4.

Kozhevnikov, G.N., Vodop’yanov, A.G., Pan’kov, V.K., and Kuz’min, B.P., Complex processing of bauxite and red mud, Tsvetn. Met. (Moscow), 2013, no. 12, pp. 36–39.

Atasoy, A., The comparison of the Bayer process wastes on the base of chemical and physical properties, J. Therm. Anal. Calorim., 2007, vol. 90, no. 1, pp. 153–158.

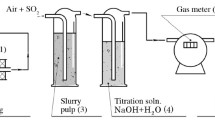

Fois, E., Lallai, A., and Mura, G., Sulfur dioxide absorption in a bubbling reactor with suspensions of Bayer red mud, Ind. Eng. Chem. Res., 2007, vol. 46, no. 21, pp. 6770–6776.

Vaclavikova, M., Misaelides, P., Gallios, G., et al., Removal of cadmium, zinc, copper and lead by red mud, an iron oxides containing hydro metallurgical waste, in Oxide Based Materials. New Sources, Novel Phases, New Applications, Amsterdam: Elsevier, 2005, vol. 155, pp. 517–525.

Piga, L., Pochetti, F., and Stoppa, L., Recovering metals from red mud generated during alumina production, J. Met., 1993, vol. 45, no. 11, pp. 54–59.

Jamieson, E., Jones, A., Cooling, D., and Stockton, N., Magnetic separation of Red Sand to produce value, Min. Eng., 2006, vol. 19, no. 15, pp. 1603–1605.

Pyagai, I.N., Yatsenko, S.P., and Pasechnik, L.A., RF Patent 2483131, Byull. Izobret., 2013, no. 15.

Liu, Li Y., Luan, C., Peng, Z., et al., Phosphate removal from aqueous solutions using raw and activated red mud and fly ash, J. Hazard. Mater., 2006, vol. 137, no. 1, pp. 374–383.

Mohapatra, B.K., Mishra, B.K., and Mishra, C.R., Investigation on alumina discharge into the red mud pond at Nalco’s Alumina Refinery, Damanjodi, Orissa, India, Proc. Technical Sessions, presented by TMS Aluminum Committee at the TMS 140 Annual Meeting and Exhibition “Light Metals 2011,” San Diego, California, February 27–March 3, 2011, New York: Wiley, 2011.

Wang, H., She, X.-F., Zhao, Q.-Q., Xue, Q.-G., and Wang, J.-S., Chin. J. Process. Eng., 2012, vol. 12, no. 5, pp. 816–821.

Li, X.-B., Xiao, W., Liu, W., et al., Recovery of alumina ferric oxide from Baer red mud rich in iron by reduction sintering Trans. Non-Ferrous Metal Soc. China, 2009, vol. 19, no. 5, pp. 1342–1347.

Ercag, E. and Apak, R., Furnace smelting and extractive metallurgy of red mud: recovery of TiO2, Al2O3 and pig iron, J. Chem. Technol. Biotechnol., 1997, vol. 70, no. 3, pp. 241–246.

Horvath, G., Red mud smelting experiments, Act Tech. Acad. Sci. Hung., 1974, vol. 79, nos. 3–4, pp. 413–449.

The Making Shaping and Treating of Steel, Pittsburg, PA: AISI Steel Found., 1998, 11th ed.

Klauber, C., Gräfe, M., and Power, G., Review of Bauxite Residue “Re-use” Options, CSIRO Document DMR-3609, Karawara: CSIRO Miner., 2009.

Vegman, E.F., Zherebin, B.N., Pokhvisnev, A.N., et al., Metallurgiya chuguna (Metallurgy of Cast Iron), Moscow: Akademkniga, 2004.

The 20th anniversary of Nikolaev Alumina Refinery, Materialy nauchno-tekhnicheskoi konferentsii (Proc. Sci.-Tech. Conf.), Nikolaev: Nikolaevsk. Glinozem. Zavod, 2000.

Besedin, A.A., Utkov, V.A., Brichkin, V.N., and Sizyakov, V.M., Red mud sintering, Obogashch. Rud, 2014, no. 2, pp. 28–31.

Bratygin, E.V., Gazaleeva, G.I., Dmitrieva, E.G., and Kalugin, Ya.I., Study of enriched red mud in the production of high-fluxed agglomerates for their further processing in blast furnaces, Materialy pyatoi mezhdunarodnoi konferentsii “Metallurgiya—INTEKhEKO–2012” (Proc. Fifths Int. Conf. “”Metallurgy—INTEKhEKO–2012”), Moscow, 2012, pp. 63–67.

Author information

Authors and Affiliations

Corresponding author

Additional information

Original Russian Text © V.L. Trushko, V.A. Utkov, A.A. Sivushov, 2017, published in Stal’, 2017, No. 8, pp. 63–65.

About this article

Cite this article

Trushko, V.L., Utkov, V.A. & Sivushov, A.A. Reducing the environmental impact of blast furnaces by means of red mud from alumina production. Steel Transl. 47, 576–578 (2017). https://doi.org/10.3103/S0967091217080149

Received:

Published:

Issue Date:

DOI: https://doi.org/10.3103/S0967091217080149