Abstract

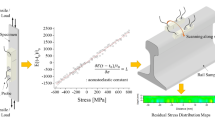

The velocity of Rayleigh waves is correlated with the depth of the decarburized layer and the hardness of rail steel. With increase in the depth of the decarburized layer and decrease in the hardness, the velocity of Rayleigh waves increases. Conversely, in the same conditions, the coercive force of the rail steel declines. The thickness of the decarburized layer is determined by this method and confirmed by direct measurements.

Similar content being viewed by others

References

Ermolov, I.N. and Lange, Yu.V., Nerazrushayushchii kontrol’: spravochnik. Tom 3. Ul’trazvukovoi kontrol’ (Nondestructive Testing: A Handbook, Vol. 3: Ultrasonic Testing), Klyuev, V.V., Ed., Moscow: Mashinostroenie, 2004.

Murav’ev, V.V. and Boyarkin, E.V., Nondestructive testing of the structural-mechanical state of currently produced rails on the basis of the ultrasonic wave velocity, Russ. J. Nondestr. Test., 2003, vol. 39, no. 3, pp. 189–197.

Bobrov, V.T., Bobrov, S.V., and Danilov, V.N., Propagation of pulses of shear elastic SH-polarization waves in a solid layer in a direction orthogonal to its surfaces, Russ. J. Nondestr. Test., 2013, vol. 49, no. 8, pp. 436–445.

Babkin, S.E., The determination of the Poisson ratio for ferromagnetic materials using the EMA method, Russ. J. Nondestr. Test., 2015, vol. 51, no. 5, pp. 303–307.

Murav’eva, O.V., Petrov, K.V., Sokov, M.Yu., and Gabbasova, M.A., The simulation and study of the propagation of the acoustic waves that are radiated by an electromagnetic–acoustic trough-type transducer over the elliptic cross-section of a bar, Russ. J. Nondestr. Test., 2015, vol. 51, no. 7, pp. 400–406.

Ul’yanov, A.I., Zakharov, V.A., and Pospelova, I.G., Coercive force of low-carbon steels during elastic and plastic tensile deformation, Russ. Phys. J., 2015, vol. 58, no. 1, pp. 85–91.

Murav’ev, V.V., Zlobin, D.V., Len’kov, S.V., and Zverev, N.N., An instrument for measuring acoustic wave velocities in metals and alloys, Instrum. Exp. Tech., 2016, vol. 59, no. 3, pp. 476–480.

Author information

Authors and Affiliations

Corresponding author

Additional information

Original Russian Text © V.V. Murav’ev, A.V. Baiteryakov, S.V. Len’kov, V.A. Zakharov, 2017, published in Stal’, 2017, No. 8, pp. 42–44.

About this article

Cite this article

Murav’ev, V.V., Baiteryakov, A.V., Len’kov, S.V. et al. Correlation of rail structure with the Rayleigh-wave velocity and the coercive force. Steel Transl. 47, 561–563 (2017). https://doi.org/10.3103/S0967091217080125

Received:

Published:

Issue Date:

DOI: https://doi.org/10.3103/S0967091217080125