Abstract

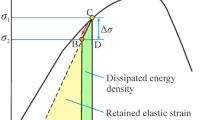

The problem of determining the loading conditions under which the maximum softening of materials is attained with minimal fracture energy consumption is posed in many practical applications (in building, explosion, drilling, grinding, metal processing by cutting, domestic and industrial waste processing, food industry, drug production, and pulp-and-paper industry). Nowadays, in many of these areas, the fracture energy consumption is rather large and ill grounded. Comparison of energy consumption by different loading programs allows one to distinguish energy saving loading conditions which can be recommended to improve the structures and operation modes of various equipment, in particular, in the field of grinding of hard materials. In the present paper, it is proposed to estimate the energy consumption according to the damage summation law expressed in terms of relative energy consumption indices.

Similar content being viewed by others

References

M. A. Miner, “Cumulative Damage in Fatigue,” J. Appl. Mech. 12(3), 159–164 (1945).

E. L. Robinson, “Effect of Temperature Variation on the Long-Time Rupture Strength of Steels,” Trans. ASME 74(5), 777–781 (1952).

R. W. Bailey, “The Utilization of Creep Test Data in Engineering Design,” The Institution of Mechanical Engrs. Proc. 131, 131–349 (1935).

Abo el Ata and I. Finni, “Study of Laws of Damage Summation in Creep,” Teoret. Osnovy Inzh. Raschetov, No. 3, 21–32 (1972).

R. A. Arutyunyan, Problem of Strain Aging and Long-Time Fracture in Mechanics of Materials (Izd-vo St. Petersburg Univ., St. Petersburg, 2004) [in Russian].

J. Lemetr and A. Plamtri, “Utilization of the Notion of Damage in Calculations of Fracture under Conditions of Simultaneous Fatigue and Creep,” Teoret. Osnovy Inzh. Raschetov, No. 3, 124–134 (1979).

J. Collins, Failure of Materials in Mechanical Design (Wiley, New York, 1981; Mir, Moscow, 1984).

A. Fatemi and L. Young, “Cumulative Fatigue Damage and Life Prediction Theories: A Survey of the State of the Art for Homogeneous Materials,” Int. J. Fatigue 20(1), 9–34 (1998).

H. Mayer, C. Ede, and J. E. Allison, “Influence of Cyclic Loads below Endurance Limit or Threshold Stress Intensity on Fatigue Damage in Cast Aluminum Alloy,” Int. J. Fatigue 27(2), 139–141 (2005).

A. Westwood and J. Pikkens, “Use of Fracture,” in Atomic Theory of Fracture (Mir, Moscow, 1987) [in Russian].

R. A. Arutyunyan, L. I. Doktorenko, V. V. Drozdov, and V. M. Chebanov, “Vulnerability of Damage and Failure of Organic Glass in Alternating Long-Term and Cyclic Loading,” Dokl. Akad. Nauk SSSR 287(4), 810–812 (1986) [Sov. Phys. Dokl. (Engl. Transl.) 31, 355–358 (1986)].

C. E. Feltner and J. D. Morrow, “Microplastic Strain Hysteresis Energy as a Criterion for Fatigue Fracture,” Trans. ASME 83(1), 15–22 (1961).

Author information

Authors and Affiliations

Corresponding author

Additional information

Original Russian Text © R.A. Arutyunyan, 2012, published in Izvestiya Akademii Nauk. Mekhanika Tverdogo Tela, 2012, No. 4, pp. 63–70.

About this article

Cite this article

Arutyunyan, R.A. Estimate of energy consumption in fracture of solids. Mech. Solids 47, 426–432 (2012). https://doi.org/10.3103/S0025654412040073

Received:

Published:

Issue Date:

DOI: https://doi.org/10.3103/S0025654412040073