Abstract—

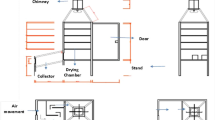

The results of numerical simulation for investigating and estimating heat efficiency of a combined solar-fuel dryer of the cradle-conveyor type heated by direct solar radiation and by infra-red irradiation (IR lamps) are presented in the paper. All calculations are performed for the case of the “empty” condition of the drying chamber and “inoperative” mode of IR lamps. In these cases, the amount of heat received from solar radiation (the solar radiation flux is constant and equal to 800 W/m2) is investigated and established at various values of the volumetric flow rate of the drying agent (air flow with a constant input temperature of 20°C) ranging from 100 to 1200 m3/h. The heat efficiency of a solar-fuel dryer under the same solar radiation fluxes and ambient temperature and at the input of drying agent is increased by 5 times when the volumetric flow rate of the drying agent is increased by 12 times. According to the obtained data the main growth of heat efficiency, i.e., the optimal heat efficiency, takes place under a volumetric flow rate of drying agent of 700 and 800 m3/h under the mentioned ambient parameters. We perform hydrodynamic analysis for clarifying how turbulence influences thermal performances of the dryer.

Similar content being viewed by others

REFERENCES

Chua, K.J., et al., Radiant-convective drying of osmotic treated agro-products: effect on drying kinetics and product quality, Food Control, 2004, vol. 15, no. 2, pp. 145–158.

Chua, K.J., Chou, S.K., Ho, J.C., Mujumdar, A.S., and Hawlader, M.N.A., Cyclic air temperature drying of guava pieces: Effects on moisture and ascorbic acid contents, Transactions of IChemE, Part CP, 2000a, vol. 78, pp. 72–78.

Chua, K.J. and Chou, S.K., New hybrid drying technologies, Emerging Technologies for Food Processing, Elsevier, 2005, part 20, pp. 536–551.

Ginzburg, A.S., Application of Infrared Radiation in Food Processing, London: Leonard Hill Books, 1969.

Paakkonen, K., Havento, J., Galambosi, B., and Pyykkonen, M., Infrared drying of herb, Agric. Food Sci. Finl., 1999, vol. 8, pp. 19–27.

Dontigny, P., Angers, P., and Supino, M., Graphite slurry dehydration by infrared radiation under vacuum conditions, Drying, 1992, vol. 92, pp. 669–678.

Zbicinski, I., Jakobsen, A., and Driscoll, J.L., Application of infra-red radiation for drying of particulate material, Drying, 1992, vol. 92, pp. 704–711.

Dostie, M., Seguin, J.N., Maure, D., et al., Preliminary measurements on the drying of thick porous materials by combinations of intermittent IR and continuous convection heating, Drying, 1989, vol. 89, pp. 513–520.

Carroll, M.B. and Churchill, S.W., A numerical study of periodic on-off versus continuous heating by conduction, Numer. Heat Transfer, 1986, vol. 10, pp. 297–310.

El-Mesery, H.S. and Mwithiga, G., Performance of a convective, infrared and combined infrared-convective heated conveyor-belt dryer, J. Food Sci. Technol., 2015, vol. 52, no. 5, pp. 2721–2730.

Pathare, P.B. and Sharma, G.P., Effective moisture diffusivity of onion slices undergoing infrared convective drying, Biosyst. Eng., 2006, vol. 93, no. 3, pp. 285–291.

Burdo, O.G., Terziev, S.G., Yarovoi, I.I., and Borshch, A.A., Electromagnetic technologies for raw material dehydration, Vost.-Evr. Zh. Peredovykh Tekhnol., 2015, vol. 4, no. 8, p. 76.

Mikhailov, V.M., Kiptelaya, L.V., Saenko, S.Yu., and Zagorul’ko, A.N., Computer simulation of heat flow distribution in an IR dryer, Vestn. Nats. Tekh. Univ. Kharkiv Politekh. Inst., 2014, no. 49 (1091), p. 65.

Iskandarov, Z.S., Khalimov, A.S., and Tangrieva, Z.S., Evaluation of the influence of thermal and hydrodynamic parameters of the drying agent on the thermal power of a solar-fuel cradle-conveyor type dryer, Mukobil energiya manbalaridan foidalanishning dolzarb muammolari Respublika ilmii amalii anzhumani materiallari (Proceedings of the Republican Scientific-Practical Conference on Current Issues in the Use of Alternative Energy Sources), Bukhara, Uzbekistan, 2015.

Iskandarov, Z.S., Kombinirovannye solnechno-toplivnye sushil’nye ustanovki (Combined Solar-Fuel Dryers), Tashkent: Fan, 2005.

Ginzburg, A.S., et al., Teplofizicheskie kharakteristiki kartofelya, ovoshchei i plodov (Thermophysical Characteristics of Potatoes, Vegetables, and Fruits), Moscow: Agropromizdat, 1987.

Yufa, A.I. and Mukhiddinov, D.N., USSR Inventor’s Certificate no. 1048272, Byull. Izobret., 1983, no. 38.

Il’yasov, S.G., Theoretical foundations of infrared irradiation of food products, Doctoral (Tech.) Sci. Dissertation, Moscow: Mosk. Tekhnol. Inst. Pishch. Prom., 1977.

Nurumbetov, A.K., Research and development of means for electromechanization of the oscillating mode of drying fruits and grapes, Cand. Sci. (Tech.) Dissertation, Tashkent, 1979.

Radzhabov, A., Ismailov, M., and Muratov, Kh., Nauchnye osnovy energeticheskogo sovershenstvovaniya proizvodstva sukhofruktov i kishmisha (Scientific Foundations of Energy Improvement in the Production of Dried Fruits and Sultana Raisin), Tashkent: Mekhnat, 1993.

Sazhin, B.S., Osnovy tekhniki sushki (Fundamentals of Drying Technique), Moscow: Khimiya, 1984.

Silich, A.A., Zozulevich, B.V., and Panovskii, V.G., Sushka plodov i vinograda v tunnel’nykh sushilkakh (Drying of Fruit and Grapes in Tunnel Dryers), Moscow: Legkaya i pishchevaya promyshlennost’, 1982.

Kats, Z.A. and Rysin, A.N., Sushka pishchevykh produktov v vibrokipyashchem sloe (Drying of Food Products in a Vibrofluidized Bed), Moscow: TsNIITEI-pishcheprom, 1972.

Grishin, M.A., Intensification of the drying process of food plant materials, Extended Abstract of Doctoral (Tech.) Dissertation, Odessa, 1974.

Alimbaev, A.U., Development of a combined drying plant for grapes, Cand. Sci. (Tech.) Dissertation, Tashkent, 1986.

Zafrin, E.Ya., Bologa, M.K., and Roman, B.F., Intensification of the freeze-drying process with microwave energy supply, Elektron. Obrab. Mater., 1977, no. 2, pp. 71–73.

Katson, S. and Smit, D.V., Sublimatsionnaya sushka pishchevykh produktov (Freeze Drying of Food Products), Moscow: Pishchevaya promyshlennost’, 1968.

Lebedev, A.D. and Berel’man, T.N., Teplo- i massoobmen v protsessakh sublimatsii v vakuume (Heat and Mass Transfer in Sublimation Processes in Vacuum), Moscow: Energiya, 1975.

Rudenko, N., et al., USSR Inventor’s Certificate no. 908300, Byull. Izobret., 1982, no. 8.

Grishin, M.A., et al., Ustanovki dlya sushki pishchevykh produktov. Spravochnik (Food Drying Plants. Reference Book), Moscow: Agropromizdat, 1989.

Déribéré, M., Les applications pratiques des rayons infrarouges, Paris: Dunod, 1953.

Levitin, I.B., Primenenie IK tekhniki v narodnom khozyaistve (The Use of IR Technology in the National Economy), Leningrad: Energoizdat, 1981.

Melekh, E.N., Ustanovki IK-nagreva dlya sushki fruktov: Otchet KB Po ul’trazvukam i vysokochastotnym ustanovkam (IR Heaters for Drying Fruit: KB Report on Ultrasonics and High Frequency Machines), 1964.

Hii, C.L., Jangam, S.V., Ong, S.P., and Mujumdar, A.S., Solar Drying: Fundamentals, Applications and Innovations, Singapore, 2012, pp. 1–50.

Bena, B. and Fuller, R.J., Natural convection solar dryer with biomass back-up heater, Sol. Energy, 2002, vol. 72, no. 1, pp. 75–83.

Condori, M., Echazu, R., and Saravia, L., Solar drying of sweet pepper and garlic using the tunnel greenhouse dryer, Renewable Energy, 2001, vol. 22, pp. 447–460.

Amer, B.M.A., Hossain, M.A., and Gottschalk, K., Design and performance evaluation of a new hybrid solar dryer for banana, Energy Convers. Manage., 2010, vol. 51, pp. 813–820.

Colijn, H., Mechanical conveyors and elevators-CPI workhorses, Chem. Eng., 1978, vol. 85, pp. 43–58.

Jumah, R.Y. and Mujumdar, A.S., Dryer feeding systems, in Handbook of Industrial Drying, Mujumdar, A.S., Ed., New York: Marcel Dekker, 1995.

Roberts, A.W., The influence of granular vortex motion on the volumetric performance of enclosed screw conveyors, Powder Technol., 1999, vol. 104, pp. 56–67.

Marinelli, J. and Carson, J.W., Use screw feeders effectively, Chem. Eng. Prog., 1992, vol. 88, pp. 47–51.

Nonhebel, G. and Moss, A.A.H., Drying of Solids in the Chemical Industry, London: Butterworth, 1971.

Funding

The authors express that no funding has been received for this study.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

The authors declare that they have no conflicts of interest.

Additional information

Translated by Yu. Zikeeva

About this article

Cite this article

Iskandarov, Z.S., Sataev, M.I., Azimov, A.M. et al. Hydrodynamic Analysis of a Solar-Fuel Dryer of the Cradle-Conveyor Type Combined with Infrared Radiation. Appl. Sol. Energy 57, 528–535 (2021). https://doi.org/10.3103/S0003701X21060098

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.3103/S0003701X21060098