Abstract

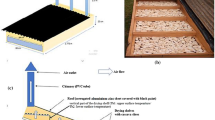

This article presents a household solar dryer’s experimental performance for drying banana and presents modelling of the solar dryer for drying banana. This new type of solar dryer setup consists of a parabolic roof structure covered with a polycarbonate sheet on a collector flat plate. This solar dryer has a base of 0.90 × 1.90 m2 and 0.45 m in height. Two 9-W DC fans powered by one 20-W PV modules were used to ventilate the dryer. Drying experiments have been a performance for banana during from January to September 2019. To investigate the experimental performance, the dryer was used to dry 10 full-scale experimental runs, and 10 kg of ripe bananas were dried for each experiment. The air temperature inside the dryer varied from 35 to 55°C from 8:00 am to 6:00 pm. The moisture content of banana decrease from an initial moisture content of 72% (wb) to a final moisture content of 20% (wb) within 4 days, whereas the moisture content with natural sun dried was reduced to 32% (wb) under similar weather conditions. The banana being dried in this solar dryer was completely protected from animals, rain, and insects, and good quality product in terms of flavor and texture were obtained. A system of partial differential equations describing heat and moisture transfer during drying of banana was developed and solved numerically using the finite difference method. The simulated moisture contents agreed well with the experimental data for the solar drying of banana.

Similar content being viewed by others

REFERENCES

Hoesinzadeh, S., Zakeri, M.H., Shirkhani, A., and Chamkha, A.J., Analysis of energy consumption improvements of a zero-energy building in a humid mountainous area, J. Renewable Sustainable Energy, 2019, vol. 11, art. id. 015103.

Hoseinzadeh, S., Yargholi, R., Kariman, H., and Heyns, P.S., Exergoeconomic analysis and optimization of reverse osmosis desalination integrated with geothermal energy, Environ. Prog. Sustainable Energy, 2020, vol. 39, no. 5, art. id. e13405.

Yargholi, R., Kariman, H., Hoseinzadeh, S., Bidi, M., and Naseri, A., Modeling and advanced exergy analysis of integrated reverse osmosis desalination with geothermal energy, Water Supply, 2020, vol. 20, no. 3, pp. 984–996.

Hoseinzadeh, S. and Azadi, R., Simulation and optimization of a solar-assisted heating and cooling system for a house in Northern of Iran, J. Renewable Sustainable Energy, 2017, vol. 9, art. id. 045101.

Nezhad, M.E.Y. and Hoseinzadeh, S., Mathematical modelling and simulation of a solar water heater for an aviculture unit using MATLAB/SIMULINK, J. Renewable Sustainable Energy, 2017, vol. 9, art. id. 063702.

Janjai, S., Lakanaboonsong, J., Nunez, M., and Thongsathitya, A., Development of a method for generating operational solar radiation maps from satellite data for satellite data for a tropical environment, Sol. Energy, 2005, vol. 78, no. 6, pp. 739–751.

Bala, B.K., Solar Drying Systems: Simulations and Optimization, Udaipur, India: Agrotech Publishing Academy, 1998.

Mühlbauer, W., Present status of solar crop drying, Energy Agric., 1986, vol. 5, no. 2, pp. 121–137.

Chauhan, P.S. and Kumar, A., Performance analysis of greenhouse dryer by using insulated north–wall under natural convection mode, Energy Rep., 2016, vol. 2, pp. 107–116.

Dina, S.F., Ambarita, H., Napitupulu, F.H., and Kawai, H., Study on effectiveness of continuous solar dryer integrated with desiccant thermal storage for drying cocoa beans, Case Studies Therm. Eng., 2015, vol. 5, pp. 32–40.

Akhatov, J.S., Samiev, K.A., Mirzaev, M.S., and Ibraimov, A.E., Study of the thermal technical characteristics of a combined solar desalination and drying plant, Appl. Sol. Energy, 2018, vol. 54, no. 2, pp. 49–58.

Pangavhane, D.R., Sawhney, R.L., and Sarsavadia, P.N., Design, development and performance testing of a new natural convection solar dryer, Energy, 2002, vol. 27, no. 6, pp. 579–590.

Sekyere, C.K.K., Forson, F.K. and Adam, F.W., Experimental investigation of the drying characteristics of a mixed mode natural convection solar crop dryer with back up heater, Renewable Energy, 2016, vol. 92, pp. 532–542.

Simate, I.N., Optimization of mixed-mode and indirect-mode natural convection solar dryers, Renewable Energy, 2003, vol. 28, no. 3, pp. 435–453.

Bezbaruah, P.J., Das, R.S., and Sarkar, B.K., Overall performance analysis and GRA optimization of solar air heater with truncated half conical vortex generators, Sol. Energy, 2020, vol. 196, pp. 637–652.

Bezbaruah, P.J., Das, R.S., and Sarkar, B.K., Solar air heater with finned absorber plate and helical flow path: a CFD analysis, Appl. Sol. Energy, 2020, vol. 56, no. 1, pp. 35–41.

Chauhan, P.S., Kumar, A., and Nuntadusit, C., Heat transfer analysis of PV integrated modified greenhouse dryer, Renewable Energy, 2018, vol. 121, pp. 53–65.

Fterich, M., Chouikhi, H., Bentaher, H., and Maalej, A., Experimental parametric study of a mixed-mode force convection solar dryer equipped with a PV/T air collector, Sol. Energy, 2018, vol. 171, pp. 751–760.

Karthikeyan, A.K. and Murugavelh, S., Thin layer drying kinetics and exergy analysis of turmeric (Curcuma longa) in a mixed mode forced convection solar tunnel dryer, Renewable Energy, 2018, vol. 128, pp. 305–312.

Lakshmi, D.V.N., Muthukumar, P., Layek, A., and Nayak, P.K., Performance analysis of mixed mode forced convection solar dryer for drying of stevia leaves, Sol. Energy, 2019, vol. 188, pp. 507–518.

Lamnatou, C., Papanicolaou, E., Belessiotis, V., and Kyriakis, N., Experimental investigation and thermodynamic performance analysis of a solar dryer using an evacuated-tube air collector, Appl. Energy, 2012, vol. 94, pp. 232–243.

Rathore, N.S. and Panwar, N.L., Experimental studies on hemi cylindrical walk-in type solar tunnel dryer for grape drying, Appl. Energy, 2010, vol. 87, no. 8, pp. 2764–2767.

Singh, P.L. Silk cocoon drying in forced convection type solar dryer, Appl. Energy, 2011, vol. 88, no. 5, pp. 1720–1726.

Wang, W., Li, M., Hasanien, R.H.E., Wang, Y., and Yang, L., Thermal performance of indirect forced convection solar dryer and kinetics analysis of mango, Appl. Therm. Eng., 2018, vol. 134, pp. 310–321.

Janjai, S., Srisittipokakun, N., and Bala, B.K., Experimental and modelling performances of a roof-integrated solar drying system for drying herbs and spices, Energy, 2008, vol. 33, no. 1, pp. 91–103.

Janjai, S., Lamlert, N., Intawee, P., et al., Experimental and simulated performance of a PV-ventilated solar greenhouse dryer for drying of peeled longan and banana, Sol. Energy, 2009, vol. 83, no. 9, pp. 1550–1565.

Sevik, S., Aktas, M., Dolgun, E.C., et al., Performance analysis of solar and solar infrared dryer of mint and apple slices using energy-exergy methodology, Sol. Energy, 2019, vol. 180, pp. 537–549.

Afriyie, J.K., Rajakaruna, H., Nazha, M.A.A., and Forson, F.K., Simulation and optimisation of the ventilation in a chimney-dependent solar crop dryer, Sol. Energy, 2011, vol. 88, no. 7, pp. 1523–1531.

Tarigan, E., Mathematical modeling and simulation of a solar agricultural dryer with back-up biomass burner and thermal storage, Case Studies Therm. Eng., 2018, vol. 12, pp. 149–165.

Duran, G., Condorí, M., and Altobelli, F., Simulation of a passive solar dryer to charqui production using temperature and pressure networks, Sol. Energy, 2015, vol. 119, pp. 310–318.

Kituu, G.M., Shitanda, D., Kanali, C.L., et al., Thin layer drying model for simulating the drying of Tilapia fish (Oreochromis niloticus) in a solar tunnel dryer, J. Food Eng., 2010, vol. 98, no. 3, pp. 325–331.

Motahayyer, M., Arabhosseini, A., and Akhijahani, H.S., Numerical analysis of thermal performance of a solar dryer and validated with experimental and thermo-graphical data, Sol. Energy, 2019, vol. 193, pp. 692–705.

Akhatov, Zh.S. and Khalimov, A.S., Numerical calculations of heat engineering parameters of a solar greenhouse dryer, Appl. Sol. Energy, 2015, vol. 51, no. 2, pp. 107–111.

Prem Kumar, T., Naveen, C., and Premalatha, M., Performance analysis of 2 in 1 parabolic trough collector for both hot water and hot air production for domestic household applications, Appl. Sol. Energy, 2019, vol. 55, no. 6, pp. 397–403.

Nukulwar, M.R. and Tungikar, V.B., Evaluation of drying model and quality analysis of turmeric using solar thermal system, Appl. Sol. Energy, 2020, vol. 56, no. 4, pp. 233–241.

Duffie, J.A. and Beckman, W.A., Solar Engineering of Thermal Processes, New York: John Wiley & Sons, 1991.

Kays, W.M. and Crawford, M.E., Convective Heat and Mass Transfer, New York: McGraw-Hill, 1980.

Smitabhindu, R., Janjai, S., and Chankong, V., Optimization of a solar-assisted drying system for drying bananas, Renewable Energy, 2008, vol. 33, no. 7, pp. 1523–1531.

Guarte, R.C., Mühlbauer, W., and Kellert, M., Drying characteristics of copra and quality of copra on coconut oil, Postharvest Biol. Technol., 1996, vol. 9, no. 3, pp. 361–372.

ASHRAE Handbook: Fundamentals, Atlanta, GA: American Society of Heating, Refrigerating and Air-Conditioning Engineers, 1997.

Mohsenin, N.N., Thermal Properties of Food and Agricultural Materials, New York: Gordon and Breach Science, 1980.

Janjai, S., Masiri, I., Pattarapanitchai, S., and Laksanaboonsong, J., Mapping global solar radiation from long-term satellite data in the tropics using and improved model, Int. J. Photoenergy, 2013, vol. 2013, art. id. 210159.

Nguyen, M.H. and Price, W.E., Air-drying of banana: influence of experimental parameters, slab thickness, banana maturity and harvesting season, J. Food Eng., 2007, vol. 79, no. 1, pp. 200–207.

Pankaew, P., Aumporn, O., Janjai, S., Mundpookhiew, T., and Bala, B.K., Performance of parabolic greenhouse solar dryer equipped with rice husk burning system for banana drying, J. Renewable Energy Smart Grid Technol., 2019, vol. 14, no. 1, pp. 52–65.

O’Callaghan, J.R., Menzies, D.J., and Bailey, P.H., Digital simulation of agricultural drier performance, J. Agric. Eng. Res., 1971, vol. 16, no. 3, pp. 223–244.

ACKNOWLEDGMENTS

The author would like to thank the Division of Physics, Faculty of Science and Technology, Thepsatri Rajabhat University for the support of the equipment in this project.

Author information

Authors and Affiliations

Corresponding author

About this article

Cite this article

Nabnean, S., Nimnuan, P. Experimental and Modelling Performances of a Household Solar Dryer for Drying Banana. Appl. Sol. Energy 57, 34–43 (2021). https://doi.org/10.3103/S0003701X21010059

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.3103/S0003701X21010059