Abstract

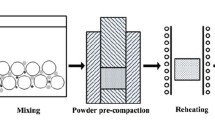

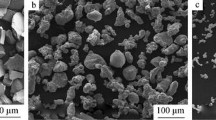

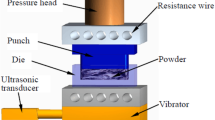

Commercial F500 SiC powder and 6061Al powder were chosen to fabricate the mid-fraction SiC particles (SiCp)/6061Al composite of 30 vol % (volume fraction) SiC using a pressureless sintering technique. Decantation of the SiC powder and optimization of the sintering temperature were performed to improve the microstructure and properties of the composite. The results show that near full-densification of the 30 vol % SiCp/6061Al composite sintered at 680°C is achieved, and no SiCp/Al interfacial reaction occurs. The composite possess the following set of properties: relative density of 98.2%, bending strength of 425.6 MPa, thermal conductivity (TC) of 159 W/(m K) and coefficient of thermal expansion (CTE) of 12.5 × 10–6/°C (20–100°C). The fracture of the composite occurs via cleavage of the SiC particles and ductile tearing of the Al alloy matrix, indicating a strong SiCp/Al interface bonding.

Similar content being viewed by others

REFERENCES

Ma, P., Wei, Z.J., Jia, Y.D., Yu, Z.S., Prashanth, K.G., Yang, S.L., Li, C.G., Huang, L.X., and Eckert, J., Mechanism of formation of fibrous eutectic Si and thermal conductivity of SiCp/Al–20Si composites under high pressure, J. Alloys Compd., 2017, vol. 709, pp. 329–336.

Thermal Transfer Composites, http://www.thermaltc.com/products.html, accessed April 15, 2017.

Fang, M., Hu, L., Yang, L., Shi, C.D., Wu, Y.C., and Tang, W.M., Electroless plating and growth kinetics of Ni–P alloy film on SiCp/Al composite with high SiC volume fraction, Trans. Nonfer. Met. Soc. China, 2016, vol. 26, pp. 799–805.

Wang, D.M., Zheng, Z.X., Lv, J., Xu, G.Q., Zhou, S.A., Tang, W.M., and Wu, Y.C., Enhanced thermal conductive 3D-SiC/Al–Si–Mg interpenetrating composites fabricated by pressureless infiltration, Ceram. Inter., 2017, vol. 43, pp. 1755–1761.

Jayakumar, K., Mathew, J., Joseph, M., Kumar, R.S., Shukla, A.K., and Samuel, M.G., Synthesis and characterization of A356–SiC composite produced through vacuum hot pressing, Adv. Manuf. Proc., 2013, vol. 28, pp. 991–998.

Gui, M., Kang, S.B., and Euh, K., Thermal conductivity of Al–SiCp composites by plasma spraying, Scr. Mater., 2005, vol. 52, pp. 51–56.

Hao, S. and Xie, J., Tensile properties and strengthening mechanisms of SiCp-reinforced aluminum matrix composites as a function of relative particle size ratio, J. Mater. Res., 2013, vol. 28, pp. 2047–2055.

Pieczonka, T., Schubert, T., Baunack, S., and Kieback, B., Dimensional behaviour of aluminium sintered in different atmospheres, Mater. Sci. Eng. A, 2008, vol. 478, pp. 251–256.

Mao, X.Z., Hong, Y., Wang, B.H., Liu, J.W., Zhang, Y.J., Feng, D., Yang, L., Shi, C.D., Wu, Y.C., and Tang, W.M., Fabrication, microstructures and properties of 50vol%SiC/6061Al composites via a pressureless sintering technique, Powder Metall., 2018, vol. 61, pp. 1–9.

Hafizpour, H.R. and Simchi, A., Investigation on compressibility of Al–SiC composite powders, Powder Metall., 2008, vol. 51, pp. 217–223.

Asgharzageh, H. and Simichi, A., Supersolidus liquid phase sintering of Al6061/SiC metal matrix composites, Powder Metall., 2009, vol. 52, pp. 28–35.

Kang, Z.C., Mao, D.H., and Deng, J.L., The study of measuring molten aluminium viscosity, Hunan Nonfer. Met., 2001, vol. 17, pp. 18–20.

Wang, R.M., Surappa, M.K., Tao, C.H., and Li, C.Z., Microstructure and interface structure studies of SiCp-reinforced Al(6061) metal-matrix composites, Mater. Sci. Eng. A, 1988, vol. 254, pp. 219–226.

Liu, P., Wang, A.Q., Xie, J.P., and Hao, S.M., Characterization and evaluation of interface in SiCp/2024 Al composite, Trans. Nonfer. Met. Soc. China, 2015, vol. 25, pp. 1410–1418.

Jin, P., Xiao, B.L., Wang, Q.Z., and Hao, S.M., Effect of hot pressing temperature on microstructure and mechanical properties of SiC particle reinforced aluminum matrix composites, Acta Metall. Sin., 2011, vol. 47, pp. 1025–1037.

Padmavathi, C. and Upadhyaya, A., Densification, microstructure and properties of supersolidus liquid phase sintered 6711Al–SiC metal matrix composites, Sci. Sinter., 2010, vol. 42, pp. 363–382.

Euh, K.J. and Kang, S.B., Effect of rolling on the thermo-physical properties of SiCp/Al composites fabricated by plasma spraying, Mater. Sci. Eng. A, 2005, vol. 395, pp. 47–52.

Liu, Y.Q., Fan, J.Z., Sang, J.M., and Shi, L.K., Development of metal matrix composites by powder-metallurgy processing, Mater. Rev., 2010, vol. 24, pp. 18–23.

Hao, S.M., Xie, J.P., Wang, A.Q., Wang, W.Y., Li, J.W., and Sun, H.L., Thermal expansion and mechanical properties of middle reinforcement content SiCp/Al composites fabricated by PM technology, J. Wuhan Univ. Technol. Mater. Sci. Ed., 2014, vol. 29, pp. 660–664.

ACKNOWLEDGMENTS

This work was financially supported by International Science and Technology Cooperation Program of China (grant numbers 2014DFA50860).

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

The authors claim that they have no conflict of interest.

About this article

Cite this article

Yinqiu Huang, Chen, G., Wang, B. et al. Fabrication, Microstructure and Properties of the Mid-Fraction SiC Particles/6061Al Composites Using an Optimized Powder Metallurgy Technique. Russ. J. Non-ferrous Metals 60, 312–318 (2019). https://doi.org/10.3103/S1067821219030076

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.3103/S1067821219030076