Abstract

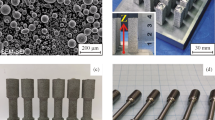

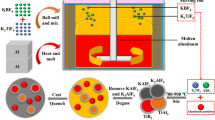

Titanium aluminide intermetallic compounds have an excellent capability for use in engineering structures at high temperatures. In the present work the formation of Nb rich inclusions in microstructure and evaporation of Al during melting of γ-TiAl based alloy (Ti-48Al-2Cr-2Nb-1B (at %)) was studied. The results show that the inclusions cannot be removed even with a four-stage melting process, when elemental Nb is used as raw material. However, by replacing Nb with NbAl3 and using a three-stage melting process, the inclusions were removed from microstructure and also evaporation of Al was reduced remarkably. Otherwise, with removing elemental Al from raw material by using TiAl compound, evaporation of Al will be very low. Increasing vessel pressure from 400 to 600 mbar will not influence evaporation of Al.

Similar content being viewed by others

References

Boyer, R., et al., Materials Properties Handbook: Ti Alloys, USA: ASM International, 1994, pp. 1011–1034

Westbrook, J.H. and Fliecher, R.L., Structural Application of Intermetallic Compounds, New York: John Wiley & Sons Ltd, 1995, pp. 77–134.

Westbrook, J.H. and Fliecher, R.L, Intermetallic Compounds- Principle and Practice, John Wiley & Sons Ltd, 2002, vol. 3, pp. 591–596.

Yanqing, S., et al., Composition Control of a TiAl During the Induction Skull Melting (ISM) Process, J. Alloys and Compounds, 2002, vol. 334, pp. 261–266.

Szkliniarz, W., et al., The Chemical Composition and Properties of Gamma-TiAl Intermetallic Phase Based Alloys Melted in Vacuum Induction Furnaces in Ceramic Crucibles, Proc. 10th World Conference on Titanium, 2003, p. 2225.

Chatterjee, A., et al., Recent Improvements in Gamma Titanium Aluminide Ingot Metallurgy, Proc. Aeromat 2000 Conference and Exhibition, Seattle, 2000.

Blum, M., et al., US Patent 20060230871, 2006.

Guther, V. et al., Microstructure and Defects in Gamma Titanium Aluminide Based Vacuum ARC Remelted Ingot Materials, Proc. Int. Symposium on Structural Intermetallics, 2001, pp. 167–172.

Jingjie, Juo, et al., Evaporation Behavior of Al during the Cold Crucible Induction Skull Melting of Titanium Aluminum Alloys, Metallurgical and Materials Trans., Ser. B, 2000, p. 837.

Alireza, Kamali, et al., AU Patent 2005100278, 2005.

Alireza, Kamali, et al., A New Process for Production of Titanium Aluminides from TiO2, J. Materials Sci. and Technology, 2007, vol. 23, no. 3, pp. 367–372.

Szkliniarz, W., et al., Effects of Boron, Carbon, and Gadolinium Additions on the Microstructure and Grain Size of Ti-48Al-2Cr-2Nb Alloy, Proc. 10th World Conference on Titanium, 2003, p. 23–47.

Brandes, E.A. and Brook, G.B., Smithells Metals Reference Book, Reed Educational and Professional Publishing Ltd, 1992, pp. 11–43.

Author information

Authors and Affiliations

Corresponding author

Additional information

The article is published in the original.

About this article

Cite this article

Hadi, M., Kamali, A.R., Khalil-Allafi, J. et al. Elimination of inclusions and evaporation control during melting of Ti-48Al-2Cr-2Nb-1B intermetallic alloy. Russ. J. Non-ferrous Metals 50, 24–29 (2009). https://doi.org/10.3103/S1067821209010076

Published:

Issue Date:

DOI: https://doi.org/10.3103/S1067821209010076