Abstract

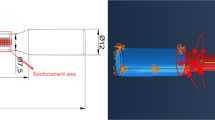

An investigation concerning the influence of laser shock processing (LSP) of stainless steel specimens made of 03Kh22N6M2 steel for the fatigue life by finite element modeling was performed. The known experimental fatigue life parameters were compared with the data taken from the finite element modeling. A conforming comparison is observed between the numerical and experimental data. It was shown that the thickness of the specimen is an important parameter during application of the LSP technology. It was found that with the decrease in the specimen thickness the fatigue life, conditioned by the LSP application, improves significantly. It was shown that for thin specimens (about 2 mm) the application of the LSP technology improves the fatigue life to 300%.

Similar content being viewed by others

REFERENCES

Peyre, P. and Fabbro, R., Laser shock processing: a review of the physics and applications, Opt. Quantum Electron., 1995, no. 27, p. 1213.

Vázquez Jiménez, C.A., Gómez Rosas, G., Rubio González, C., and Hereñú, S., Effect of laser shock processing on fatigue life of 2205 duplex stainless steel notched specimens, Opt. Laser Technol., 2017, no. 907, p. 308.

Peyre, P., Chaieb, I., and Braham, C., FEM calculations of residual stresses induced by laser shock processing in stainless steels, Model. Simul. Mater. Sci. Eng., 2007, no. 15, p. 205.

Rubio-González, C., Felix-Martinez, C., Gomez-Rosas, G., Ocaña, J.L., Morales, M., and Porro, J., Effect of laser shock processing on fatigue crack growth of duplex stainless steel, Mater. Sci. Eng., A, 2011, no. 528, p. 914.

Cuellar, S.D., Hill, M.R., DeWald, A.T., and Rankin, J.E., Residual stress and fatigue life in laser shock peened open hole samples, Int. J. Fatigue, 2012, no. 44, p. 8.

Achintha, M., Nowell, D., Fufari, D., Sackett, E.E., and Bache, M.R., Fatigue behaviour of geometric features subjected to laser shock peening: experiments and modelling, Int. J. Fatigue, 2014, no. 62, p. 171.

Ivetic, G., Three-dimensional fem analysis of laser shock peening of aluminium alloy 2024–T351 thin sheets, Surf. Eng., 2011, no. 27, p. 445.

Korsunsky, A.M., Residual elastic strain due to laser shock peening: modelling by eigenstrain distribution, J. Strain Anal. Eng. Des., 2006, vol. 41, no. 3, p. 195.

Sakhvadze, G.Zh., Features of finite element modeling of residual stresses arising in material under laser shock-wave processing using the intrinsic deformations method, J. Mach. Manuf. Reliab., 2018, vol. 47, no. 4, pp. 373–379.

Sakhvadze, G.Zh., Finite element modeling of the technology of multiple laser shock processing of materials using the eigenstrain method, J. Mach. Manuf. Reliab., 2018, vol. 47, no. 5, p. 473.

Sakhvadze, G.Zh., Gavrilina, L.V., and Kikvidze, O.G., Influence of laser spot overlap effect on residual stresses during laser-shock-wave processing of materials, J. Mach. Manuf. Reliab., 2016, vol. 45, no. 3, pp. 258–265.

Sakhvadze, G.Zh. and Gavrilina, L.V., Single and multiple laser shock processing of materials, J. Mach. Manuf. Reliab., 2015, vol. 44, no. 6, pp. 549–554.

Sakhvadze, G.Zh., Kavtaradze, R.Z., and Nikabadze, M.U., Eigenstrain modeling of laser–shock processing of materials, Russ. Eng. Res., 2006, vol. 38, no. 10, pp. 755–760.

Sakhvadze, G.Zh., Pugachev, M.S., and Kikvidze, O.G., Features of strengthening of materials by laser shock processing, Uprochn. Tekhnol. Pokryt., 2016, no. 9 (141), p. 20.

Sakhvadze, G.Zh., Bulekbaeva, G.Zh., and Kikvidze, O.G., Research of surface layers quality hardening by laser shock processing at different rates of laser spots overlapping, Probl. Mashinostr. Avtomatiz., 2016, no. 2, p. 132.

Makhutov, N.A., Prochnost’ i bezopasnost’: fundamental’nye i prikladnye issledovaniya (Strength and Safety: Basic and Applied Research), Novosibirsk: Nauka, 2008, p. 528.

Makhutov, N.A., A criterion base for assessment of strength, lifetime, reliability, survivability, and security of machines and man–machine systems, J. Mach. Manuf. Reliab., 2013, vol. 42, no. 5, pp. 364–373.

Burago, N.G., Zhuravlev, A.B., Nikitin, I.S., and Yakushev, V.L., Study of different modes of fatigue fracture and durability estimation for compressor disc of gas turbine engine, Math. Models Comput. Simul., 2016, vol. 8, no. 5, pp. 523–532.

Pavlov, V.F., Kirpichev, V.A., Kocherova, E.E., and Zlobin, A.S., Evaluation of low cycle fatigue based on the use of Coffin-Manson dependence under zero-to-‘soft’ loading cycle, Vestn. Samar. Univ., Aerokosm. Tekh., Tekhnol. Mashinostr., 2017, vol. 16, no. 1, p. 129.

Tropkin, S., Devyatov, A., Vinkler, A., Tlyasheva, R., and Zakirnichnaya, M., Predicting the fatigue strength of impellers of centrifugal pumping units using SIMULIA solutions: Abaqus, fe-safe and FlowVision hydrodynamic analysis complex, SAPR Grafika, 2014, no. 5, p. 1.

Zakirnichnaya, M.M. and Kul’sharipov I.M., Wedge gate valves safe exploitation resource calculation specifics taking into account working parameters in technological pipelines, Neftegaz. Delo, 2016, vol. 14, no. 4, p. 121.

ACKNOWLEDGMENTS

The authors are grateful to N.A. Vlasov for assistance in calculations in the finite element packages ABAQUS and FE-SAFE.

Funding

This work was supported by the Ministry of Science and Higher Education of the Russian Federation within the framework of the designated program “Investigations and Development by the Priority Development Fields of the Scientific and Technological Complex of Russia for 2014–2020,” grant no 14.607.21.0191 dated Sept. 26, 2017, project RFMEFI60717X0191.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

The authors declare that they have no conflict of interest..

Additional information

Translated by E. Grishina

About this article

Cite this article

Sakhvadze, G.Z., Kavtaradze, R.Z., Nikabadze, M.U. et al. Improvement of the Fatigue Life of Stainless Steel Specimens by Laser Shock Processing. J. Mach. Manuf. Reliab. 48, 353–360 (2019). https://doi.org/10.3103/S1052618819040137

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.3103/S1052618819040137