Abstract

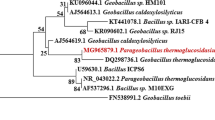

Amylases constitute one of the most important groups of enzymes for commercial use. In the present study, production of α-amylase was optimized using a newly isolated actinobacterial strain from the coral reef environment of the Gulf of Mannar Biosphere Reserve, India. It was identified as Streptomyces sp. ML12 based on chemotaxonomy, cultural and morphological characteristics, carbon source utilization and 16S rRNA gene sequencing. Fermentation variables were selected in accordance with the Plackett-Burman design and were optimized by response surface methodology. Five significant variables (rice bran and wheat bran — both agricultural byproducts, sodium chloride, magnesium sulphate and incubation period) were selected for the optimization via central composite design. The optimal features were rice bran (5.5 g/100 mL), wheat bran (5.3 g/100 mL), sodium chloride (2.8 g/100 mL), magnesium sulphate (1.4 g/100 mL) and 8 days of incubation period. Optimization of the medium with the above tested features increased the amylase yield by 4.4-fold.

Similar content being viewed by others

Abbreviations

- CCD:

-

central composite design

- ISP:

-

international Streptomyces project

- RSM:

-

response surface methodology

References

Altschul S.F., Gish W., Miller W., Myers E.W. & Lipman D.J. 1990. Basic local alignment search tool. J. Mol. Biol. 215: 403–410.

Archana A. & Satyanarayana T. 1997. Xylanase production by thermophilic Bacillus licheniformis A99 in solid-state fermentation. Enzyme Microb. Technol. 21: 12–17.

Ausubel F.M., Brent R., Kingstone R.E., Seidman J.G., Smith J.A. & Struhl K. 1999. Short Protocols in Molecular Biology. John Wiley & Sons, Ltd., New York.

Babu K.R. & Satyanarayana, T. 1995. α-Amylase production by thermophilic Bacillus coagulans in solid state fermentation. Process Biochem. 30: 305–309.

Bertoldo C. & Antranikian G. 2001. Amylolytic enzymes from hyperthermophiles. Methods Enzymol. 330: 269–289.

Broedel S.E., Papciak S.M. & Jones W.R. 2001. The selection of optimum media formulantions for improved expression of recombinant proteins in E. coli. Technical Bull. 2: 1–6.

Chen Q.H., He G.Q. & Mokhtar A.M. 2002. Optimization of medium composition for the production of elastase by Bacillus sp. EL31410 with response surface methodology. Enzyme Microb. Technol. 30: 667–672.

Deepak V., Kalishwaralal K., Ramkumarpandian S., Babu S.V., Senthilkumar S.R. & Sangiliyandi G. 2008. Optimization of media composition for Nattokinase production by Bacillus subtilis using response surface methodology. Bioresource Technol. 99: 170–174.

Dey G., Mitra A., Banerjee R. & Matri B.R. 2001. Enhanced production of α-amylase by optimization of nutritional constituents using response surface methodology. Biochem. Eng. J. 7: 227–231.

Francis F., Sabu A., Nampoothiri K.M., Ramachandran S., Ghosh S., Szakacs G. & Pandey A. 2003. Use of response surface methodology for optimizing process parameters for the production of α-amylase by Aspergillus oryzae. Biochem. Eng. J. 15: 107–115.

Gangadharan D., Sivaramakrishnan S., Nampoothiri K.M. & Pandey A. 2006. Solid culturing of Bacillus amyloliquefaciens for α-amylase production. Food Technol. Biotechnol. 44: 269–274.

Gouda M. & Elbahloul Y. 2008. Statistical optimization and partial characterization of amylases production by halotolerant Penicillium sp. World J. Agric. Sci. 4: 359–369.

Hagihara H., Igarashi K., Hayashi Y., Endo K., Ikawa-Kitayama K., Ozaki K., Kawai S. & Ito S. 2001. Novel α-amylase that is highly resistant to chelating reagents and chemical oxidants from the alkaliphilic Bacillus isolate KSM-K38. Appl. Environ. Microbiol. 67: 1744–1750.

Haq I., Ashraf H., Qadeer M.A. & Iqbal J. 2003. Production of α-amylase by Bacillus licheniformis using an economical medium. Bioresource Technol. 87: 57–61.

Hasegawa T., Takizawa M. & Tanida S. 1983. A rapid analysis for chemical grouping of aerobic actinomycetes. J. Gen. Appl. Microbiol. 29: 319–322.

Hernandez M.S., Rodriguez M.R., Guerra N.P. & Roses R.P. 2006. Amylase production by Aspergillus niger in submerged cultivation on two wastes from food industries. J. Food Eng. 73: 93–100.

Hostinova, E. 2002. Amylolytic enzymes produced by the yeast Saccharomycopsis fibuligera. Biologia 57(Suppl. 11): 247–251.

John R.P., Nampoothiri K.M. & Pandey A. 2006. Solid state fermentation for L-lactic acid production from agro wastes using Lactobacillus delbruecki. Process Biochem. 41: 759–763.

Karuppiah V., Aarthi C. & Sivakumar K. 2011. Enhancement of PCR amplification of actinobacterial 16S rRNA gene using an adjuvant, dimethyl sulphoxide. Curr. Sci. 101: 22–23.

Kar S. & Ray R.C. 2007. Partial characterization and optimization of extracellular thermostable Ca2+ inhibited α-amylase production by Streptomyces erumpens MTCC 7317. J. Sci. Ind. Res. 67: 58–64.

Khurana S., Kapoor M., Gupta S. & Kuhad R.C. 2007. Statistical optimization of alkaline xylanase production from Streptomyces violaceoruber under submerged fermentation using response surface methodology. Indian J. Microbiol. 47: 144–152.

Kimura M. 1980. A simple method for estimating evolutionary rate of base substitution through comparative studies of nucleotide sequences. J. Mol. Evol. 16: 111–120.

Kundu S., Sahu M.K., Sivakumar K. & Kannan L. 2006. Isolation and characterization of extracellular enzymes producing actinomycetes from the alimentary canal of estuarine fishes. Asian J. Microbiol. Biotechnol. Environ. Sci. 8: 811–815.

Lechevalier M.P. & Lechevalier H. 1970. Chemical composition as a criterion in the classification of aerobic actinomycetes. Int. J. Syst. Bacteriol. 20: 435–443.

Miller G.L. 1959. Use of dinitrosalicylic acid reagent for determination of reducing sugar. Anal. Chem. 31: 426–429.

Nonomura H. 1974. Key for classification and identification of 458 species of the Streptomycetes included in ISP. J. Ferment. Technol. 52: 78–92.

Parekh S., Vinci V.A. & Strobel R.J. 2000. Improvement of microbial strains and fermentation processes. Appl. Microbiol. Biotechnol. 54: 287–301.

Plackett R.L. & Burman J.P. 1946. The design of optimum maultifactorial experiments. Biometrika 33: 305–325.

Poorna C.A. & Prema P. 2007. Production of cellulase-free endoxylanase from novel alkalophilic thermotolerent Bacillus pumilus by solid-state fermentation and its application in wastepaper recycling. Bioresour. Technol. 98: 485–490.

Ramachandran S., Patel A.K., Nampoothiri K.M., Chandran S., Szakacs G., Soccol C.R. & Pandey A. 2004. α-Amylase from a fungal culture grown on oil cakes and its properties. Braz. Arch. Biol. Technol. 47: 309–317.

Rao J.L.M. & Satyanarayana T. 2003. Statistical optimization of a high maltose-forming, hyperthermostable and Ca2+-independent α-amylase production by an extreme thermophile Geobacillus thermooleovorans using response surface methodology. J. Appl. Microbiol. 95: 712–718.

Ray C.R. & Kar S. 2009. Statistical optimization of α-amylase production by Bacillus brevis MTCC 7521 in solid-state fermentation using cassava bagasse. Biologia 64: 864–870.

Saban M. T., Elibol M. & Ozer D. 2006. Optimization of growth medium for the production of α-amylase from Bacillus amyloliquefaciens using response surface methodology. J. Chem. Technol. Biotechnol. 81: 618–622.

Saitou N. & Nei M. 1987. The neighbor-joining method: a new method for reconstructing phylogenetic trees. Mol. Biol. Evol. 4: 406–425.

Shirling E. B. & Gottlieb D. 1966. Methods for characterization of Streptomyces species. Int. J. Syst. Bacteriol. 16: 313–340.

Silva C.J.S.M. & Roberto I.C. 2001. Optimization of xylitol production by Candida guilliermondii FTI 20037 using response surface methodology. Process Biochem. 36: 1119–1124.

Sivakumar K., Sahu M.K., Thangaradjou T. & Kannan L. 2007. Review on actinobacteria in India. Indian J. Microbiol. 47: 186–196.

Tamura K., Dudley J., Nei M., Kumar S. 2007. MEGA4: Molecular Evolutionary Genetics Analysis (MEGA) software version 4.0. Mol. Biol. Evol. 24: 1596–1599.

Tanyildizi S.M., Elibol M. & Ozer D. 2006.Optimization of growth medium for the production of α-amylase from Bacillus amyloliquefaciens using response surface methodology. J. Chem. Technol. Biotechnol. 81: 618–622.

Techapun C., Poosaran N., Watanabe M. & Sasaki K. 2003. Thermostable and alkaline-tolerant microbial cellulase-free xylanases produced from agricultural wastes and the properties required for use in pulp bleaching bioprocesses: a review. Process Biochem. 38: 1327–1340.

Thompson J.D., Gibson T.J., Plewniak F., Jeanmougin F. & Higgins D.G. 1997. The CLUSTAL X windows interface: flexible strategies for multiple sequence alignment aided by quality analysis tools. Nucleic Acids Res. 25: 4876–4882.

Wang S.L., Yen Y.H., Shih I.L., Changc A.C., Changa W.T., Wu W.C. & Chai Y.D. 2003. Production of xylanases from rice bran by Streptomyces actuosus A-151. Enzyme Microb. Technol. 33: 917–925.

Yang S.S. & Wang J.Y. 1999. Protease and amylase production of Streptomyces rimosus in submerged and solid state cultivations. Bot. Bull. Acad. Sin. 40: 259–265.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Sivakumar, K., Karuppiah, V., Sethubathi, G.V. et al. Response surface methodology for the optimization of α-amylase production by Streptomyces sp. ML12 using agricultural byproducts. Biologia 67, 32–40 (2012). https://doi.org/10.2478/s11756-011-0159-2

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.2478/s11756-011-0159-2